Precast high-strength building beam and column node component

A building and high-strength technology, applied to the connection method of columns at the intersection nodes and beams, can solve the problems of laborious assembly, low connection strength, poor precision, etc., to avoid local overload, high production efficiency, and gentle stress uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

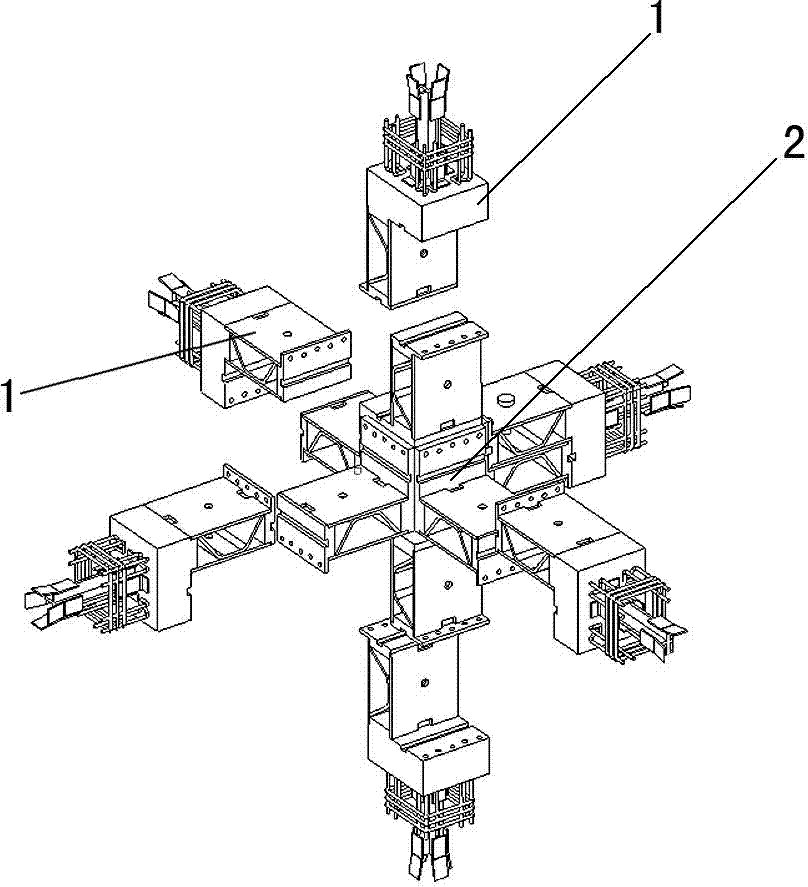

[0021] refer to figure 1 1. The prefabricated high-strength building beam and column node components of the present invention have lap joints 1 that are prefabricated to the beam and column ends, collect each lap joint at the collective joint 2 of the node, and prevent detachment of the connecting member.

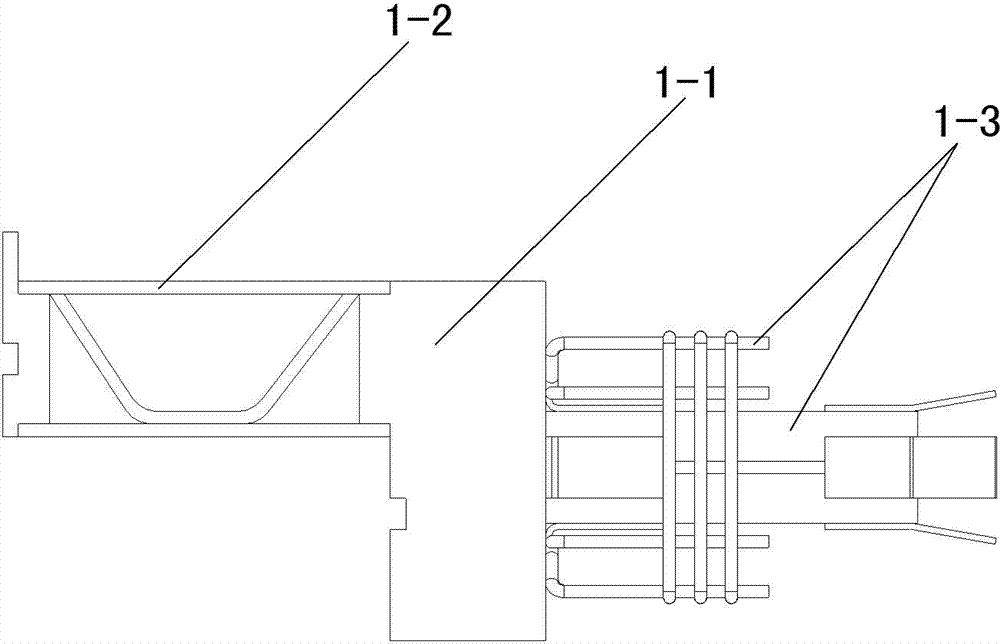

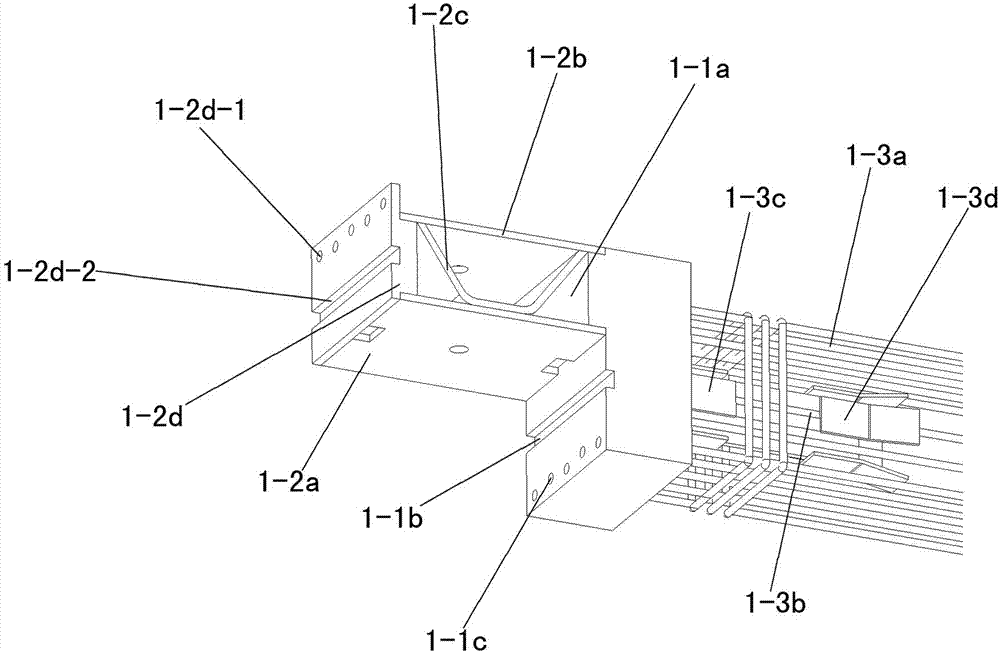

[0022] refer to figure 2 , image 3 , Figure 4 , Figure 5 , the lap joint includes a tenon seat 1-1, a lap tenon 1-2 welded on the side of the tenon seat facing the node, a tenon 1-4 welded on the side of the tenon seat facing the beam or column, and a lap tenon welded on the tenon seat One side of the end face has a lap tenon positioning rib 1-1a, and the lap joint tenon is welded by an inner side plate 1-2a and an outer plate 1-2b welded to the positioning rib on the tenon seat and welded to the tenon seat. The arched support plate 1-2c between the side plate and the outer plate is composed of a butt end 1-2d welded on the end of the inner side plate and the outer ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com