Automated laboratory machine for automatic handling of laboratory samples

An automatic processing and laboratory technology, applied in the direction of laboratory utensils, instruments, chemical instruments and methods, etc., can solve the problem of tight placement area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

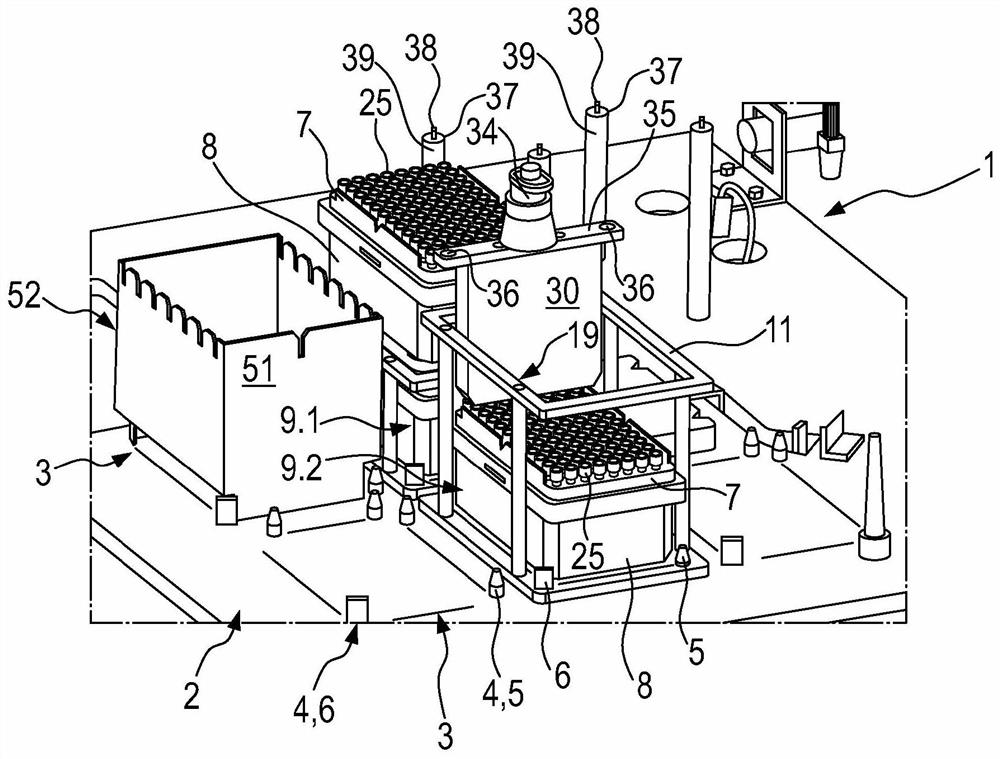

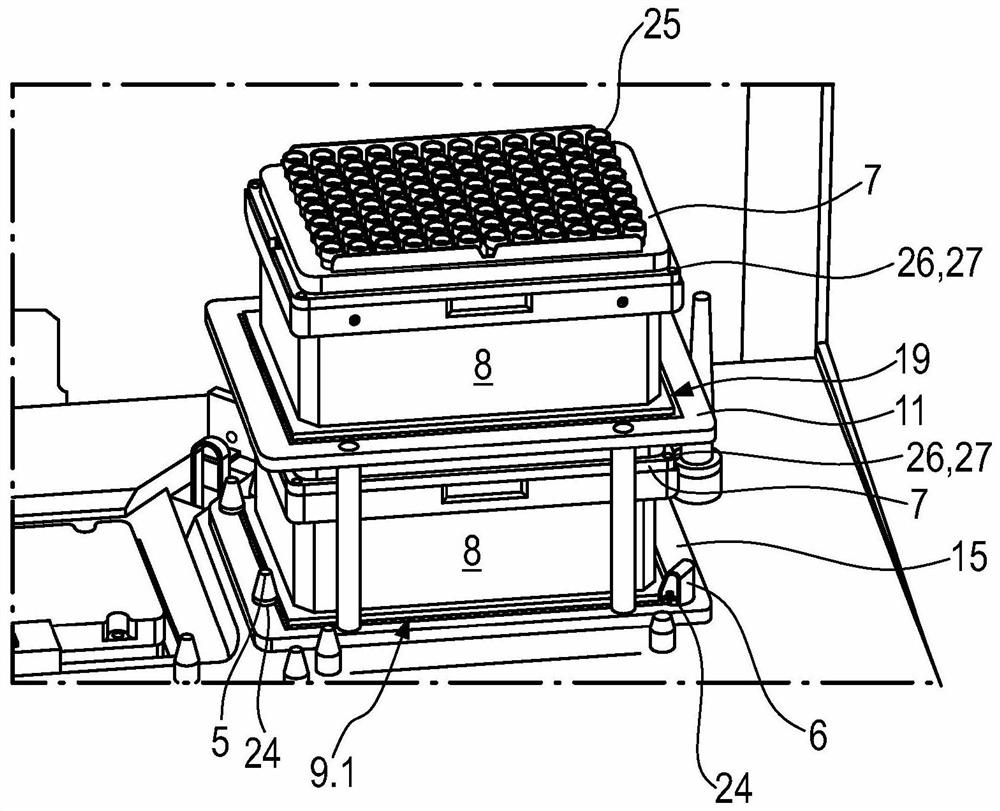

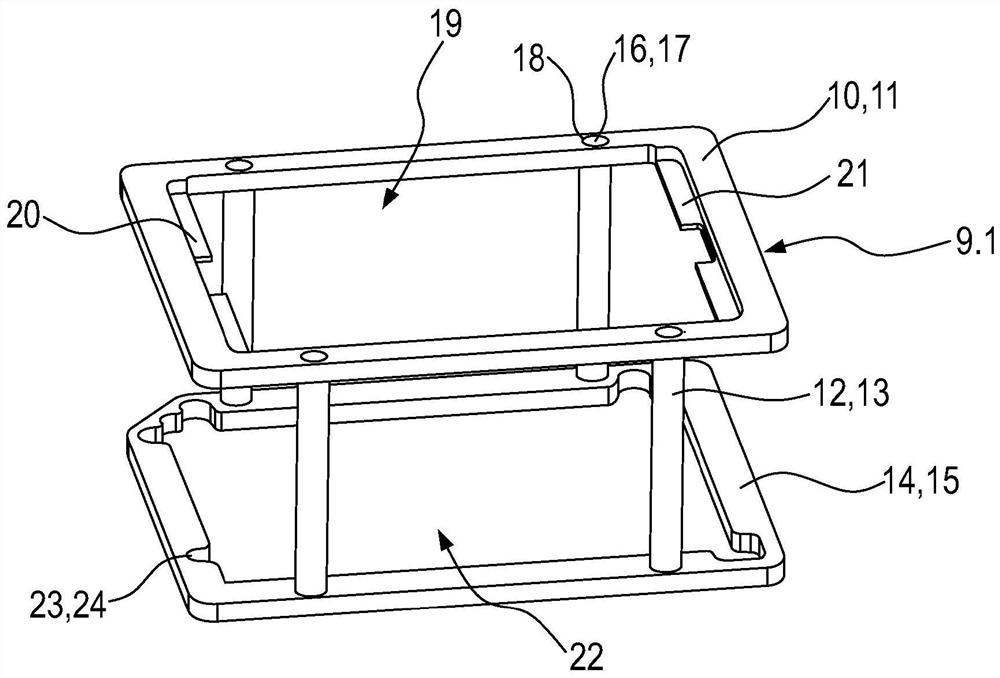

[0069] according to figure 1 , the laboratory robot 1 has a plurality of work stations 3 for standardized microtiter plates on a flat work area 2 (work plate). Correspondingly, each working station 3 has dimensions adapted to the bottom surface of a standardized microtiter plate.

[0070] Each working position 3 is defined by an assembly of first orientation elements 4 formed by four first pins 5 fixedly connected to the working area and a first spring element 6 . Two first pins 5 are arranged at the ends of one long side and one short side of the work station next to one corner of the work station. The first spring element 6 is arranged on the corner of the working position diametrically opposite the corner. Adjacent to said long side and short side of the work station 3, a further first pin 5 is arranged next to the other corner.

[0071] In this example, the laboratory robot has six work positions 3 .

[0072] A standardized microtiter plate surrounded by first orientat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com