Fuel cell unit module and fuel cell

A fuel cell unit and unit module technology, which is applied in the direction of fuel cells, electrical components, circuits, etc., can solve the problems of large differences in reaction gas temperature, humidity, and concentration, battery performance degradation, and low local gas reaction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

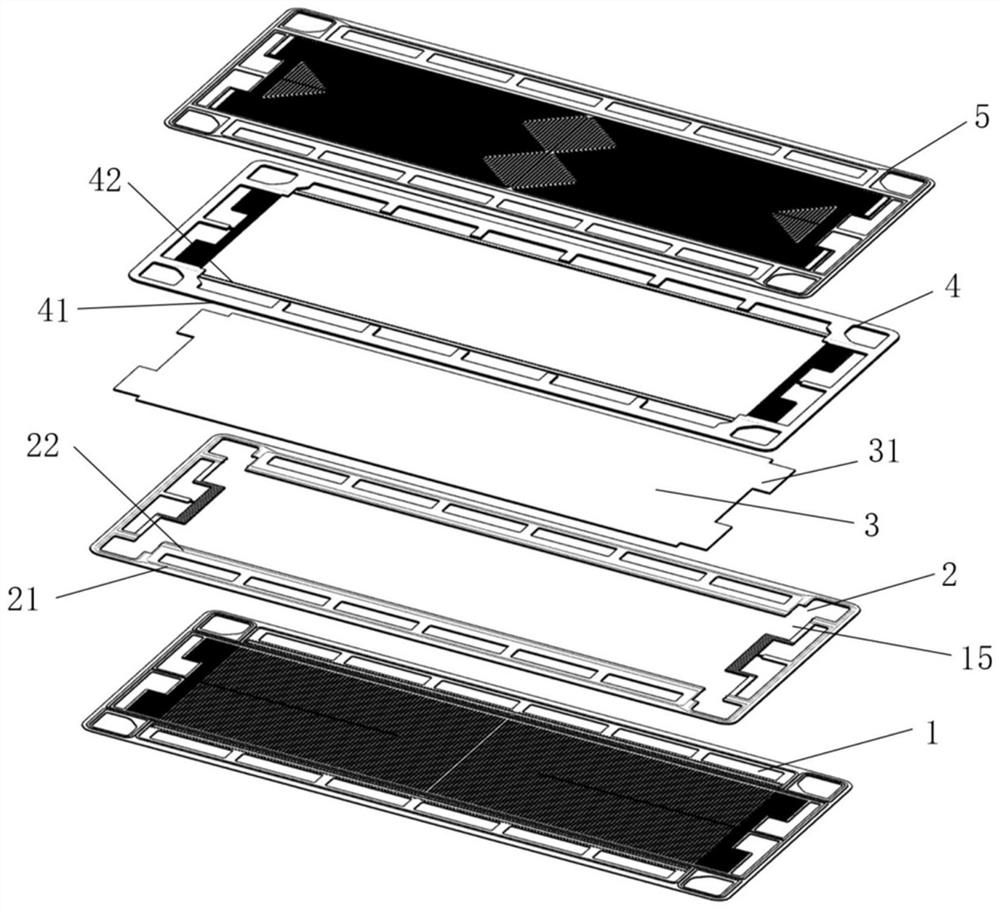

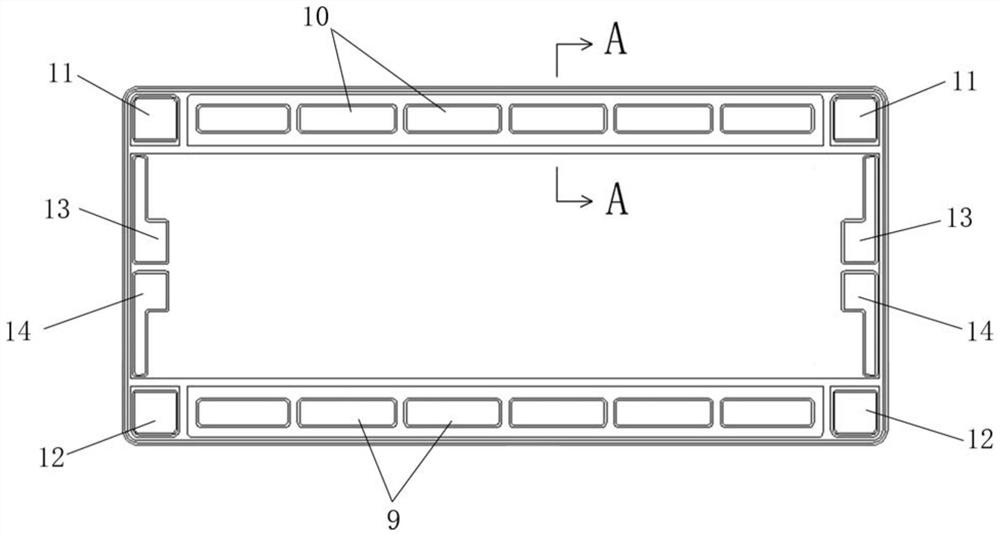

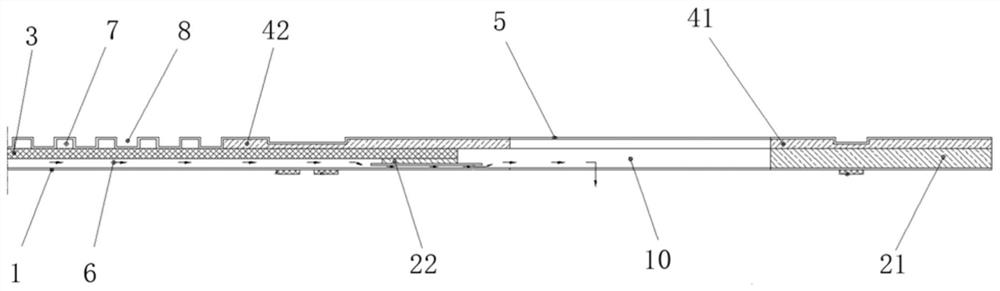

[0037] Such as Figure 1~3 As shown, this embodiment provides a fuel cell unit module, including a cathode plate 1 , a cathode injection molding seal 2 , a membrane electrode 3 , an anode injection molding seal 4 and an anode plate 5 which are sequentially stacked. The cathode injection molding seal 2 is an annular rectangular plate, including a first fitting edge 21 of the outer ring and a first clamping edge 22 of the inner ring. The anode injection molded seal 4 is also an annular rectangular plate, including a second fitting edge 41 of the outer ring and a second clamping edge 42 of the inner ring. The first fitting edge 21 and the second fitting edge 41 are attached to each other, and the surrounding sides of the membrane electrode 3 are clamped between the first clamping edge 22 and the second clamping edge 42 . The cathode plate 1 is attached to the lower layer of the cathode injection molding seal 2 , and the anode plate 5 is attached to the upper layer of the anode i...

Embodiment 2

[0045] This embodiment provides a fuel cell, including a stack core and an end plate. The electric stack core is formed by stacking fuel cell unit modules described in one embodiment of the life-death wheel, such as Figure 10 shown. This structure re-plans the smallest unit module of the core, and realizes the direct packaging of single-piece cathode plate, single-piece anode plate and membrane electrode through injection molding process. In the overall installation process of the fuel cell, only the unit modules need to be re-stacked to complete the assembly, which reduces the accuracy requirements of the traditional installation, and will not cause the bonding problem of the membrane electrode and the plate due to the installation, and improves the overall stability of the fuel cell sex.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com