Platinum-based catalyst containing uranyl phosphate tetrahydrate and preparation method thereof

A technology of uranyl phosphate tetrahydrate and catalysts, which is applied in nanotechnology for materials and surface science, electrical components, battery electrodes, etc., and can solve problems such as catalyst performance that needs to be improved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

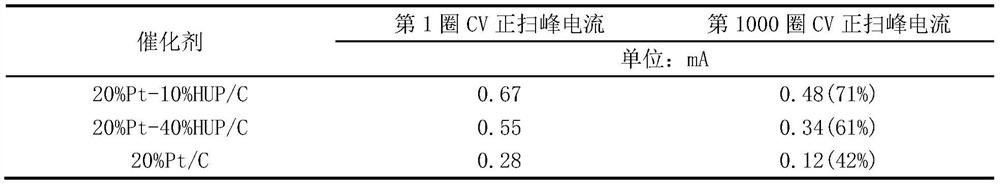

Examples

Embodiment 1

[0022] Embodiment 1: preparation embodiment

[0023] Add 140mg of Vulcan XC-72 carbon powder and 70mL of ethylene glycol into the round bottom flask in sequence, and disperse them ultrasonically to obtain a dispersion. The prepared 20 mg of uranyl phosphate tetrahydrate powder was ultrasonically dispersed in 5 mL of ultrapure water, and then poured into a flask to obtain a mixed solution. Add chloroplatinic acid solution containing 40 mg of Pt dropwise into the flask under stirring condition, then move the flask into an oil bath, stir at 140°C for 2 hours, during which high-purity nitrogen gas is continuously passed into the flask. After the flask was cooled, it was washed by ethanol centrifugally, and dried by blasting at 60°C. The resulting catalyst is noted as 20%Pt-10%HUP / C.

Embodiment 2

[0024] Embodiment 2: preparation embodiment

[0025] Put 80mg of Vulcan XC-72 carbon powder and 70mL of ethylene glycol into the round bottom flask according to this, and disperse by ultrasonic to obtain the dispersion liquid. The prepared 80 mg of uranyl phosphate tetrahydrate powder was ultrasonically dispersed in 5 mL of ultrapure water, and then poured into a flask to obtain a mixed solution. Add chloroplatinic acid solution containing 40 mg of Pt dropwise into the flask under stirring condition, then move the flask into an oil bath, and stir at 160°C for 3 hours, during which high-purity nitrogen gas is continuously passed into the flask. After the flask was cooled, it was washed with ethanol centrifugally, and dried by blowing at 50°C. The resulting catalyst was noted as 20%Pt-40%HUP / C.

Embodiment 3

[0026] Embodiment 3: preparation embodiment

[0027] Add 160mg of Vulcan XC-72 carbon powder and 70mL of ethylene glycol into the round-bottomed flask accordingly, and after ultrasonic dispersion, add 0.1mol / L sodium hydroxide solution dropwise to adjust the pH of the dispersion to >10. Add chloroplatinic acid solution containing 40 mg of Pt dropwise into the flask under stirring condition, then move the flask into an oil bath, and stir at 120°C for 4 hours, during which high-purity nitrogen gas is continuously passed into the flask. After the flask was cooled, it was washed by ethanol centrifugally, and dried by blowing at 55°C. The resulting catalyst was noted as 20% Pt / C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com