Rotating equipment service life monitoring system based on big data

A technology for rotating equipment and monitoring systems, which is used in engine testing, special data processing applications, and machine/structural component testing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

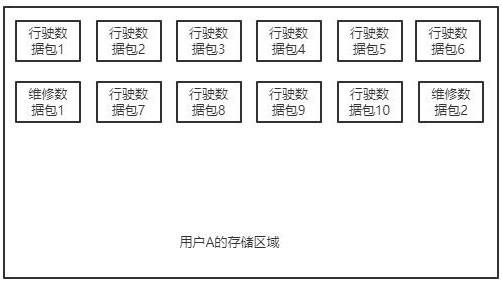

[0032] This embodiment provides a life monitoring system for rotating equipment of a rotary engine based on big data. The system includes a data processing cloud server, a driving data acquisition module, a maintenance data acquisition module and a transmission module. The driving data acquisition module is used to collect Various status data of the vehicle during driving, the maintenance data acquisition module is used to collect various data of the vehicle during engine maintenance and repair, the transmission module sends all the collected data to the data processing cloud server, the data The processing cloud server simulates the life loss value of the rotary engine based on a large amount of data;

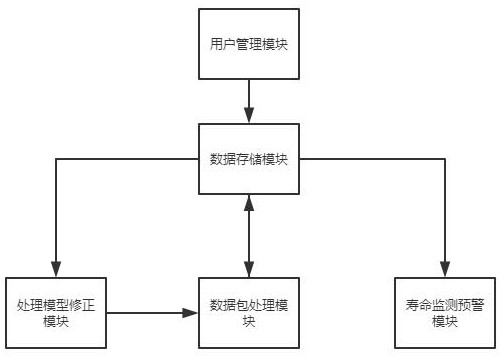

[0033] The data processing cloud server includes a user management module, a data storage module, a data packet processing module, a life monitoring and early warning module, and a processing model correction module. The user management module is used to manage the basic functi...

Embodiment 2

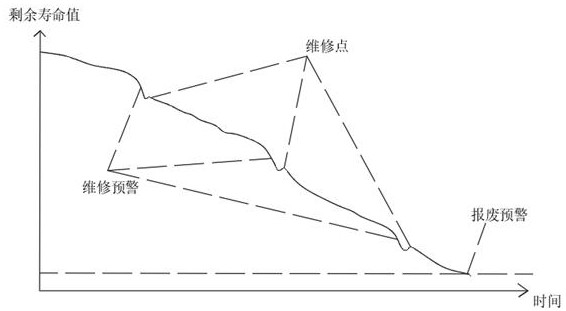

[0048] to combine figure 1 , this embodiment includes all the content of Embodiment 1. This embodiment provides a big data-based rotor engine rotating equipment life monitoring system, including a data processing cloud server, a driving data acquisition module, a maintenance data acquisition module and a transmission module. The driving data acquisition module is used to collect various status data of the vehicle during driving, the maintenance data acquisition module is used to collect various data of the vehicle during engine maintenance and repair, and the transmission module sends all the collected data to To the data processing cloud server, the data processing cloud server simulates the remaining life of the rotary engine according to a large amount of data;

[0049] The driving data acquisition module, the maintenance data acquisition module and the transmission module are integrated in a vehicle client, the vehicle client is installed in the vehicle and connected to th...

Embodiment 3

[0054] This embodiment includes all the content of the above-mentioned embodiments. The data packet processing module of this embodiment obtains road information according to the driving route, and divides the driving route into several small sections according to the road surface conditions of the road. The road of each small section of the route has For the same road conditions, at the same time, the driving information is also corresponding to several time periods, and each time period of driving information corresponds to a short route, and the data packet processing module calculates the life loss value of the rotor engine in each time period :

[0055] ;

[0056] in, is the duration of driving information corresponding to the period, Z(t) is the rotational speed function of the rotary engine, O(t) is the fuel consumption rate function, R is the road surface flatness coefficient of the corresponding route, P( ) is the rotational speed processing function, Q( ) is the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com