Purification and dehydration device for anhydrous rare earth halides

A dehydration equipment and halide technology, applied in the field of rare earths, can solve the problems of incomplete dehydration of products, unsatisfactory product quality, and large equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

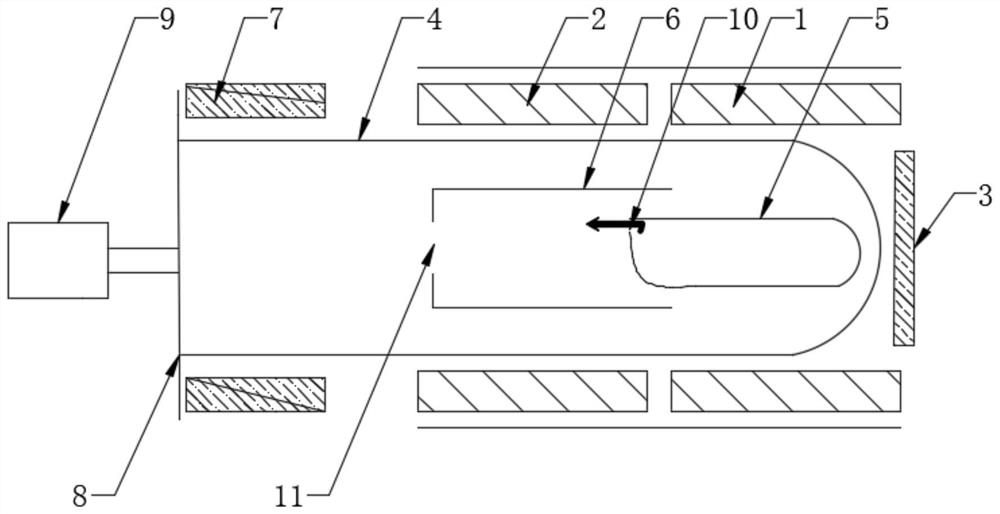

Embodiment 1

[0035] Put 500g of lanthanum chloride to be purified and dehydrated into the quartz material boat 5, place it at the bottom of the quartz tube 4, then put the quartz collector 6 into the quartz tube 4, and push it into the inlet and outlet 10 of the quartz material boat 5 8 cm into the quartz collector 6. The stainless steel cover plate 8 with the latex gasket surface is closely attached to the quartz tube 4, and the mechanical vacuum pump 9 is turned on for vacuuming. During the whole purification and dehydration process, the mechanical vacuum pump 9 continues to vacuum the vacuum chamber through the pumping pipeline. Cooling water jacket 7 passes into cooling water. After the vacuum degree reaches below 10Pa, start the heating program of the first resistance wire furnace 1 and the second resistance wire furnace 2 respectively. The second resistance wire furnace 2 is heated to maintain the temperature at about 460°C, and the first resistance wire furnace 1 is heated to 700°C....

Embodiment 2

[0037] Put 1000g of cerium bromide to be purified and dehydrated into the quartz material boat 5, place it at the bottom of the quartz tube 4, then put the quartz collector 6 into the quartz tube 4, and push it into the inlet and outlet 10 of the quartz material boat 5 Stretch into about 6cm in the quartz collector 6. The stainless steel cover plate 8 with the latex gasket surface is closely attached to the quartz tube 4, and the mechanical vacuum pump 9 is turned on for vacuuming. During the whole purification and dehydration process, the mechanical vacuum pump 9 continues to vacuum the vacuum chamber through the pumping pipeline. Cooling water jacket 7 passes into cooling water. After the vacuum degree reaches below 10Pa, start the heating program of the first resistance wire furnace 1 and the second resistance wire furnace 2 respectively, the second resistance wire furnace 2 is heated to maintain the temperature between 400-500°C, and the first resistance wire furnace 1 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com