Array impact structure based on circular truncated cone and cylindrical protrusion

A cylindrical and circular frustum technology, applied in the field of array impact structure, can solve the problems of large pressure loss, impact heat exchange flow reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0042] This implementation is an array impingement heat exchange structure based on circular truncated and cylindrical protrusions.

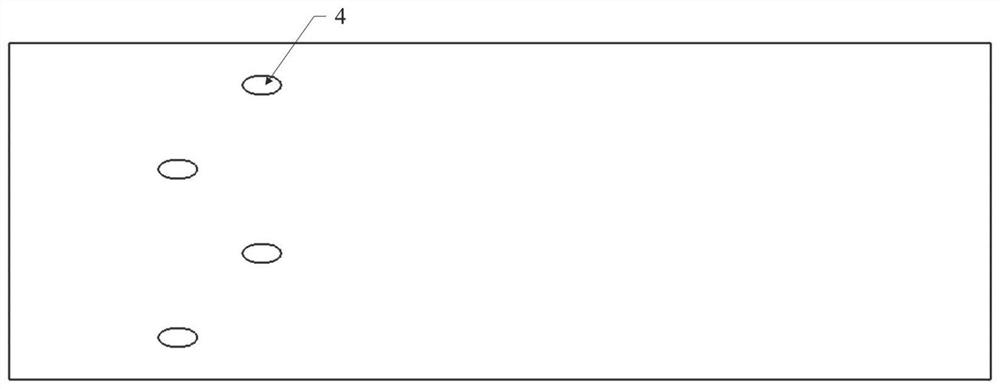

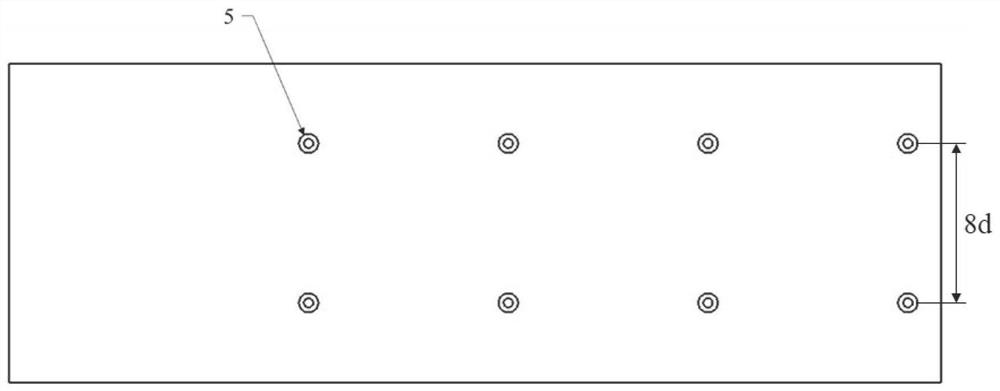

[0043] see figure 1 , the array heat exchange structure in this example is a round platform plus a cylindrical convex structure 2, located on the impact target plate 1, the bottom surface in contact with the impact target surface has a diameter of 3 mm, and the other bottom surface has a diameter of 1.5 mm and a height of 1.25 mm. The inclination angle of the wall is 45°, and the impact distance is 6mm. see figure 2 , the raised structure array is arranged on one side of the impacting target plate, the spacing in the flow direction is 30 mm, and the spacing in the span direction is 24 mm. see image 3 , the gas film hole 4 is located on the other side of the impact target plate, the hole diameter is 2.8mm, the angle between the gas film hole axis and the horizontal plane is 30°, the flow direction spacing is 12mm, the span direction spacing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Axial height | aaaaa | aaaaa |

| Angle of incidence | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com