High-wear-resistance gypsum-based self-leveling mortar and preparation method thereof

A self-leveling mortar, gypsum-based technology, applied in the field of building materials, can solve problems such as poor wear resistance and pockmarked surfaces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

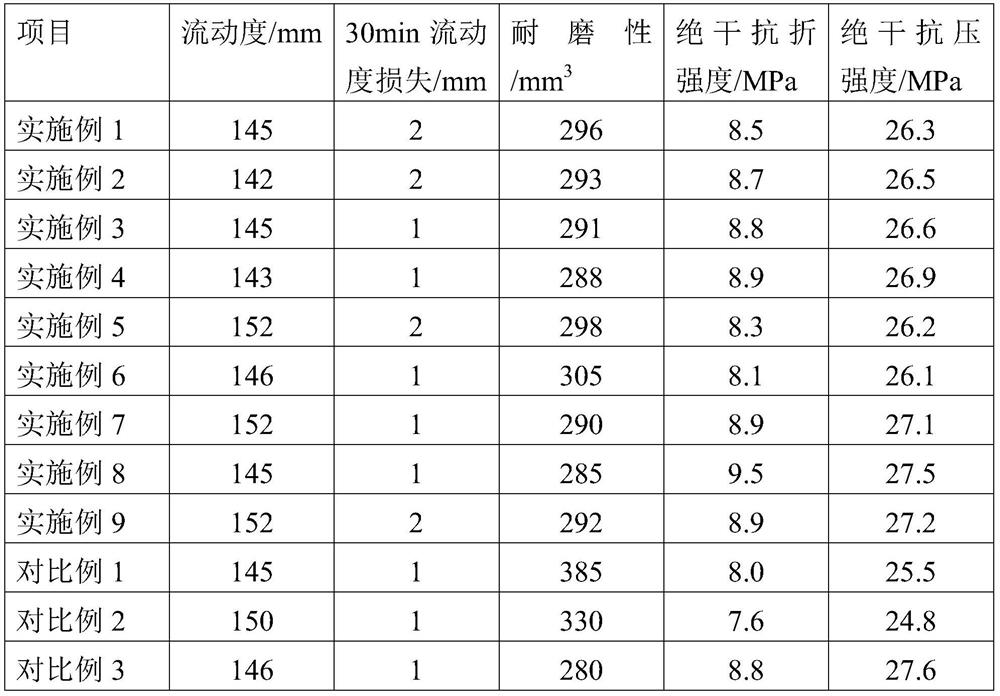

Examples

preparation example Construction

[0044] In order to further understand the high wear-resistant gypsum-based self-leveling mortar of the present invention, the present invention also provides a method for preparing a high-wear-resistant gypsum-based self-leveling mortar. The preparation method includes the following steps:

[0045] Step S1, weighing the aggregate and 50 parts of desulfurized building gypsum according to the ratio of raw materials, placing them in a pulverizer and grinding them to mix them evenly to obtain abrasives, and the particle size of the aggregates in the abrasives is below 0.16mm;

[0046] Step S2, weighing the rubber powder, retarder, water reducer, defoamer, and water retaining agent in container B according to the ratio of raw materials, and pre-mixing under stirring conditions to obtain a mixture;

[0047] Step S3: Weigh the modified reinforcing material and 50 parts of desulfurized building gypsum in container A according to the ratio of raw materials, then add the abrasive obtaine...

Embodiment 1

[0054] This embodiment provides a high wear-resistant gypsum-based self-leveling mortar. In terms of parts by mass, the gypsum-based self-leveling mortar includes the following raw material ratio: 100 parts of desulfurized building gypsum, 20 parts of modified reinforcing materials, and 90 parts of aggregate , 2.5 parts of rubber powder, 0.3 parts of retarder, 0.3 parts of water reducer, 0.2 parts of defoamer, 0.1 part of water retaining agent, and 40 parts of water.

[0055] The preparation method of the high wear-resistant gypsum-based self-leveling mortar in this example is as follows:

[0056] Step S1. Weigh 90 kg of steel slag and 50 kg of desulfurized construction gypsum according to the ratio of raw materials, place them in a pulverizer and grind them to mix them evenly to obtain abrasives, and the particle size of the steel slag in the abrasives is below 0.16 mm;

[0057] Step S2: Weigh 2.5kg of rubber powder, 0.3kg of retarder, 0.3kg of water reducer, 0.2kg of defoame...

Embodiment 2

[0061] This embodiment provides a high wear-resistant gypsum-based self-leveling mortar. In terms of parts by mass, the gypsum-based self-leveling mortar includes the following raw material ratio: 100 parts of desulfurized building gypsum, 25 parts of modified reinforcing materials, and 90 parts of aggregate , 2.5 parts of rubber powder, 0.3 parts of retarder, 0.3 parts of water reducer, 0.3 parts of defoamer, 0.1 part of water retaining agent, and 40 parts of water.

[0062] The preparation method of the high wear-resistant gypsum-based self-leveling mortar in this example is as follows:

[0063] Step S1. Weigh 90 kg of steel slag and 50 kg of desulfurized construction gypsum according to the ratio of raw materials, place them in a pulverizer and grind them to mix them evenly to obtain abrasives, and the particle size of the steel slag in the abrasives is below 0.16 mm;

[0064]Step S2. Weigh 2.5kg of rubber powder, 0.3kg of retarder, 0.3kg of water reducer, 0.3kg of defoamer...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com