Silicone rubber automatic conveying, extruding and packaging production equipment and production method

A technology for automatic conveying and production equipment, which is applied in the direction of transportation and packaging, packaging, conveyors, etc., and can solve problems such as unfavorable cleaning and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below, in conjunction with accompanying drawing and specific embodiment, the present invention is described further:

[0043] Such as figure 1 As shown, a silicone rubber automatic conveying extrusion packaging production equipment is characterized in that it includes N extrusion packaging production line branch lines, high-altitude roller conveying line 9 and palletizing bus, and the extrusion packaging production branch line is located on the high-altitude roller conveying line 9 side, the palletizing bus is located at the output end of the high-altitude roller conveyor line 9;

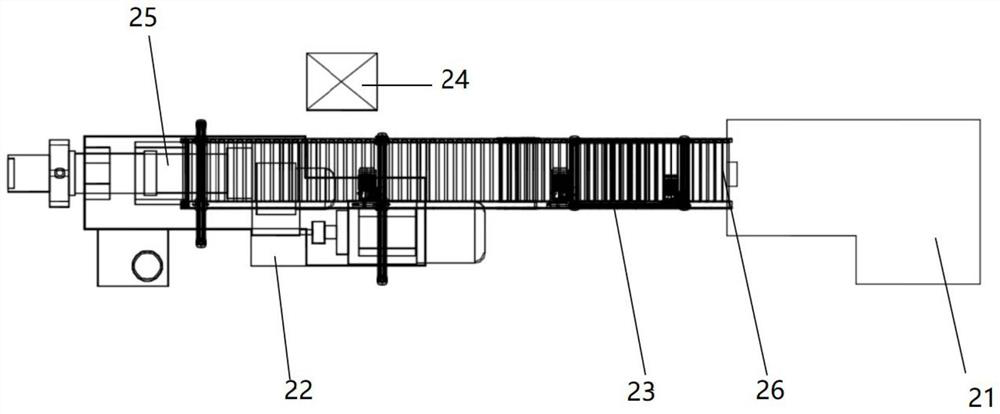

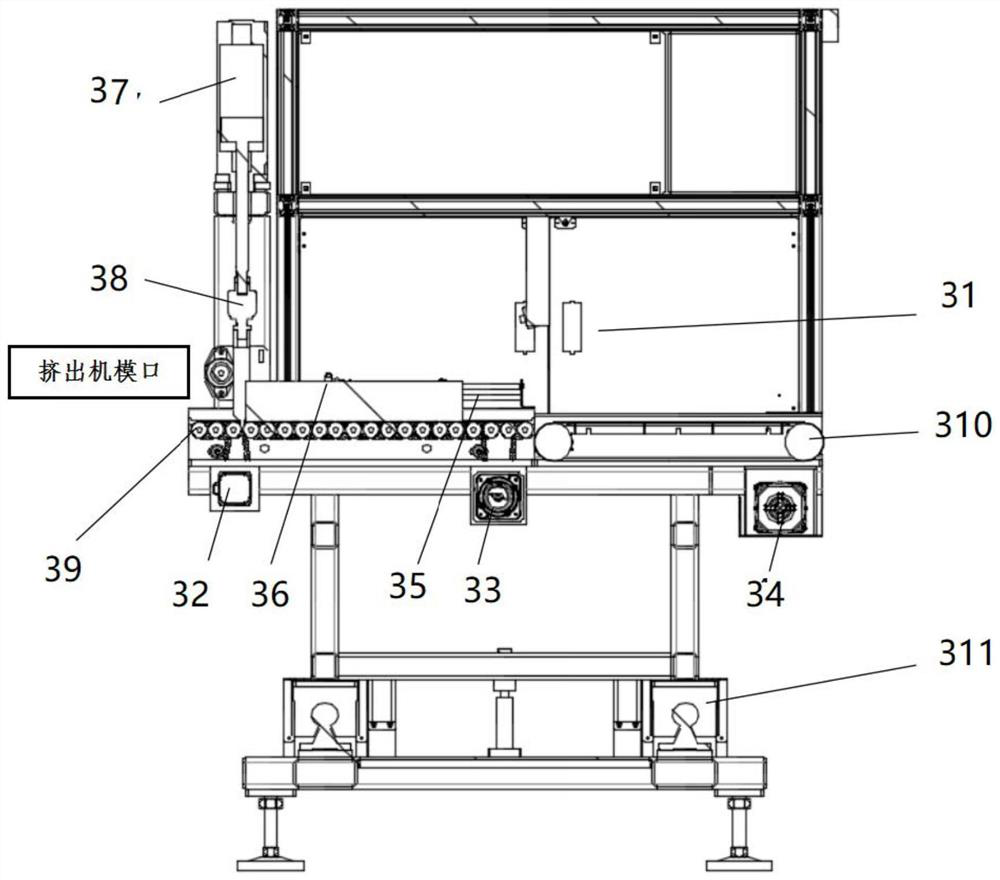

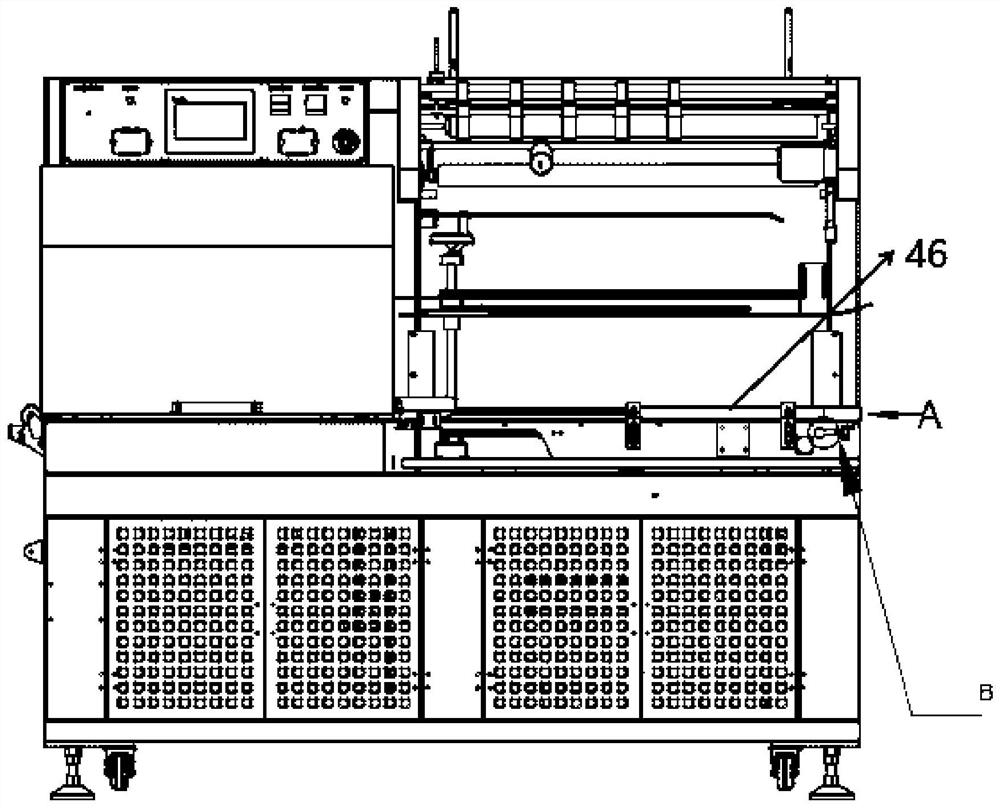

[0044] The branch line of the extrusion packaging production line is equipped with a silicone rubber cutting automatic conveying mechanism 1, an automatic fixed-length cutting mechanism 2, a weighing conveying mechanism 3, a film-coated packaging mechanism 4, a marking mechanism 5, a plastic boxing and labeling mechanism 6, Carton unpacking mechanism 7 and first two-way transmission lifting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com