Preparation method of 3D printing moldable guided bone regeneration membrane

A guided bone regeneration and 3D printing technology, applied in 3D object support structures, manufacturing tools, additive manufacturing, etc., can solve problems such as poor mechanical strength, compact structure, and rapid degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in detail below in combination with specific embodiments.

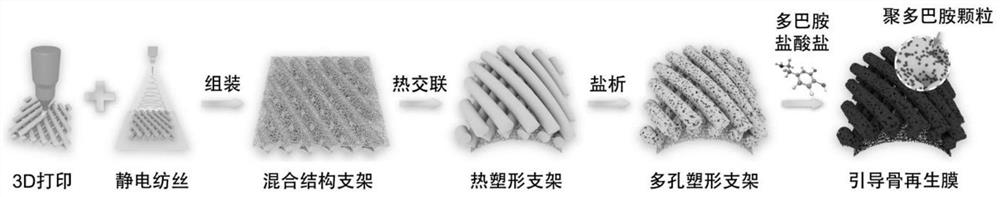

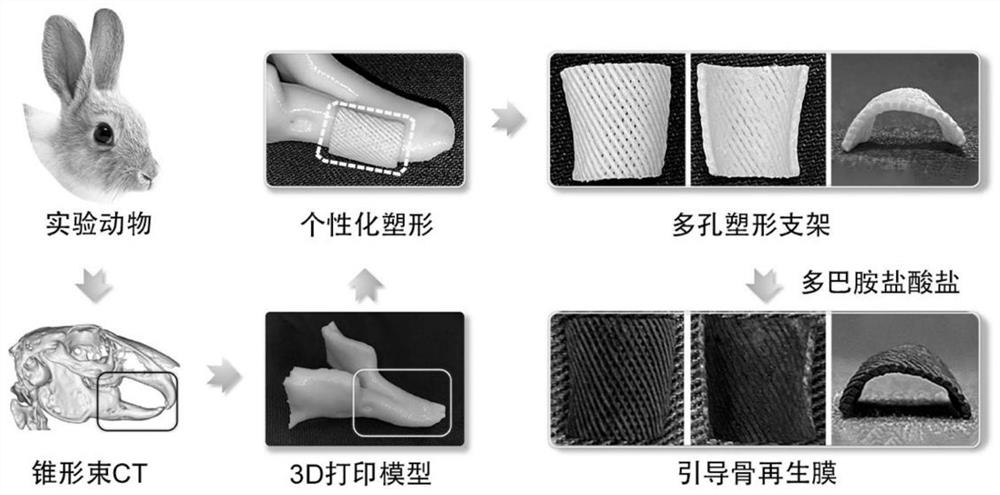

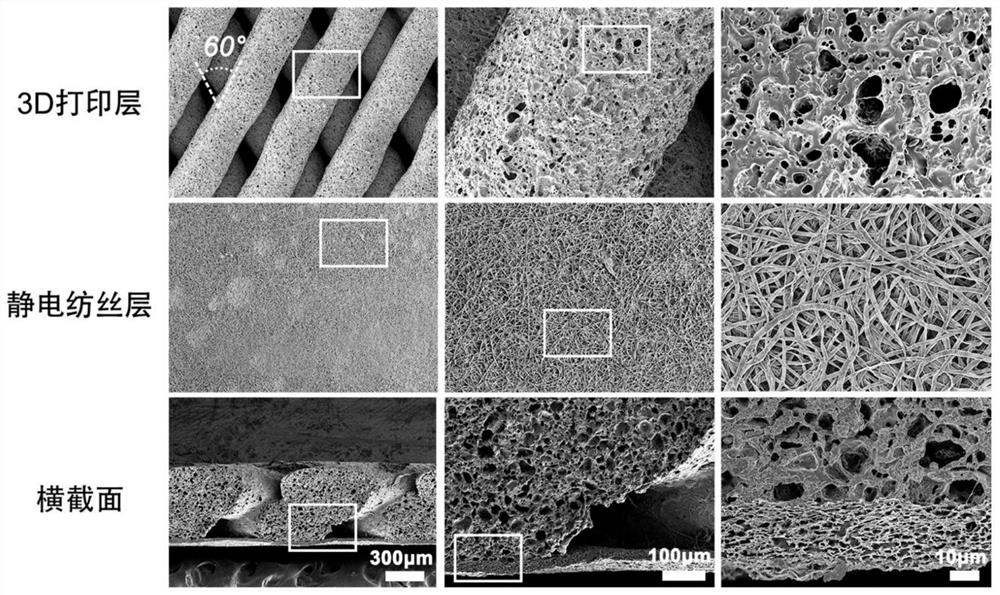

[0043] The present invention relates to a preparation method of 3D printing shapeable guiding bone regeneration membrane, and the method specifically includes the following steps:

[0044] 1. Preparation of 3D printing ink

[0045] A polymer solution was prepared by dissolving polyglycerol sebacate (polyglycerol sebacate, PGS) prepolymer and polycaprolactone (Polycaprolactone, PCL) in 100 ml of tetrahydrofuran at a mass ratio of 8:2. Use a grinder to grind the analytically pure sodium chloride particles, select 400 mesh and 500 mesh standard sample sieves, and sieve out the sodium chloride particles that can pass through the 400 mesh sieve and cannot be sieved by the 500 mesh sieve, and the diameter is about 30-38 microns. Sodium chloride particles with a diameter of 30-38 microns are added to the above polymer solution, and the added mass is twice the total mass of PGS...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com