Differential pressure gauge machining equipment and using method thereof

A processing equipment, differential pressure gauge technology, applied in metal processing equipment, metal processing, mechanical equipment and other directions, can solve the problems of incomplete assembly, unstable clamping, affecting assembly efficiency and the quality of the whole machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

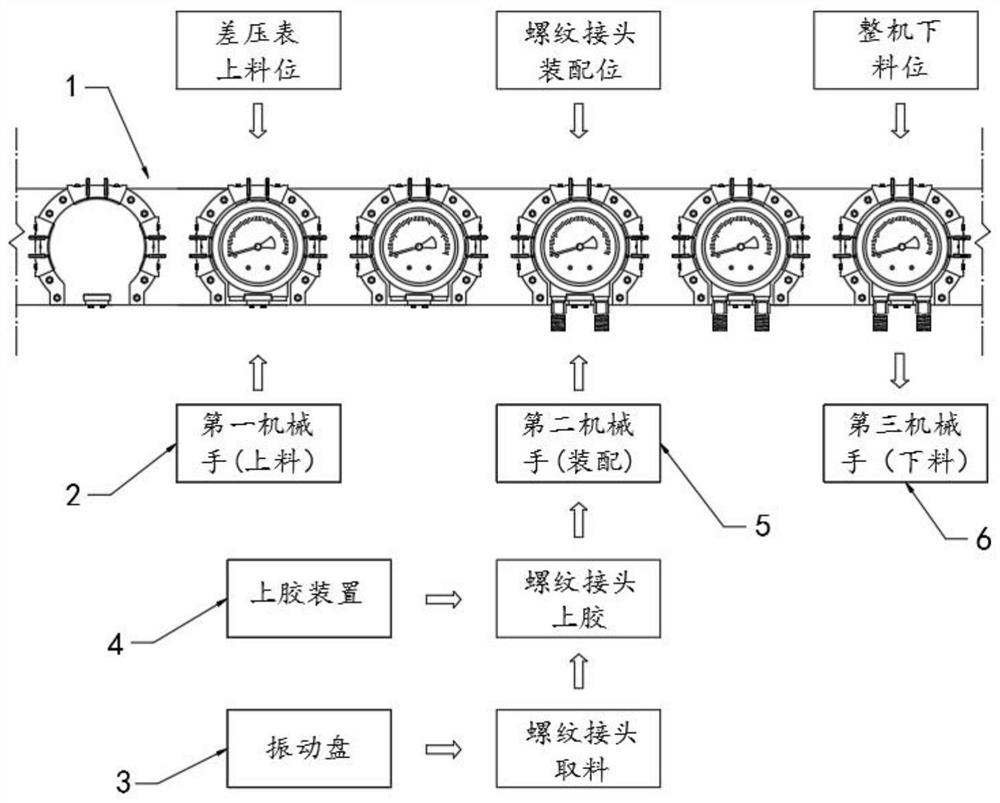

[0047] Such as Figure 1-8 As shown, a differential pressure gauge processing equipment proposed by an embodiment of the present invention, the structure of the differential pressure gauge is as follows Figure 7 As shown, the differential pressure gauge processing equipment includes:

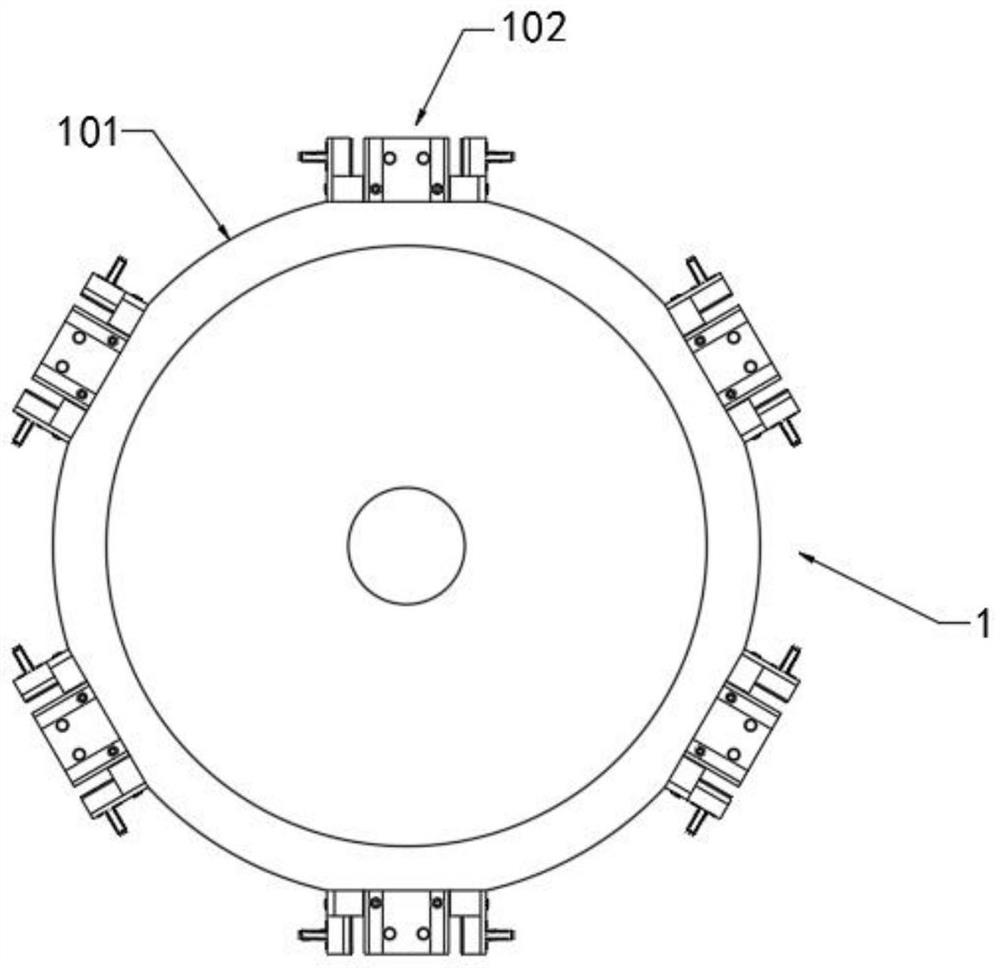

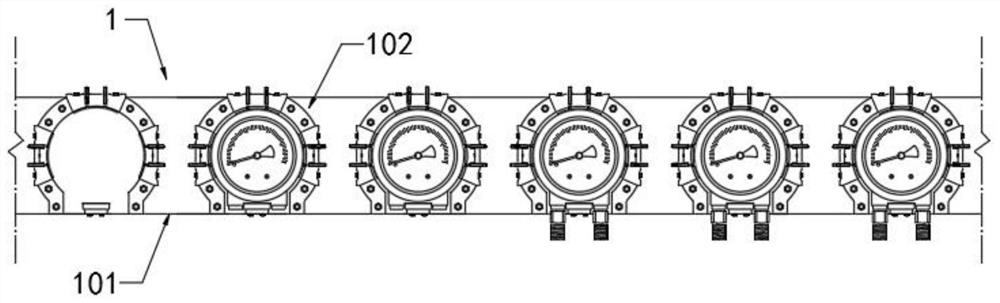

[0048] Rotary disk mechanism 1, such as figure 1 As shown, there are at least three processing stations including a differential pressure gauge upper material level, a threaded joint assembly position, and a complete machine lower material level. A turntable 101 and an actuator that drives the turntable 101 to rotate intermittently (not shown in the figure), Among them, the positions of the upper material level of the differential pressure gauge, the assembly position of the threaded joint and the lower material level of the complete machine are arranged in sequence. The outer edge of the turntable 101 is evenly distributed with positioning mechanisms 102 in the circumferential direction. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com