Explosion-proof glass plate of laboratory fume hood and laboratory fume hood

A glass plate and fume hood technology, which is applied in the laboratory field, can solve the problems of the fume hood failing to discharge poisonous gas, explosion-proof function, potential safety hazards, and inconvenient arm operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] This embodiment describes an explosion-proof glass plate of a laboratory fume hood. The explosion-proof glass plate has better explosion-proof performance to ensure the safety of operators during the experiment.

[0053] The explosion-proof glass plate in this embodiment 1 is a transparent glass plate.

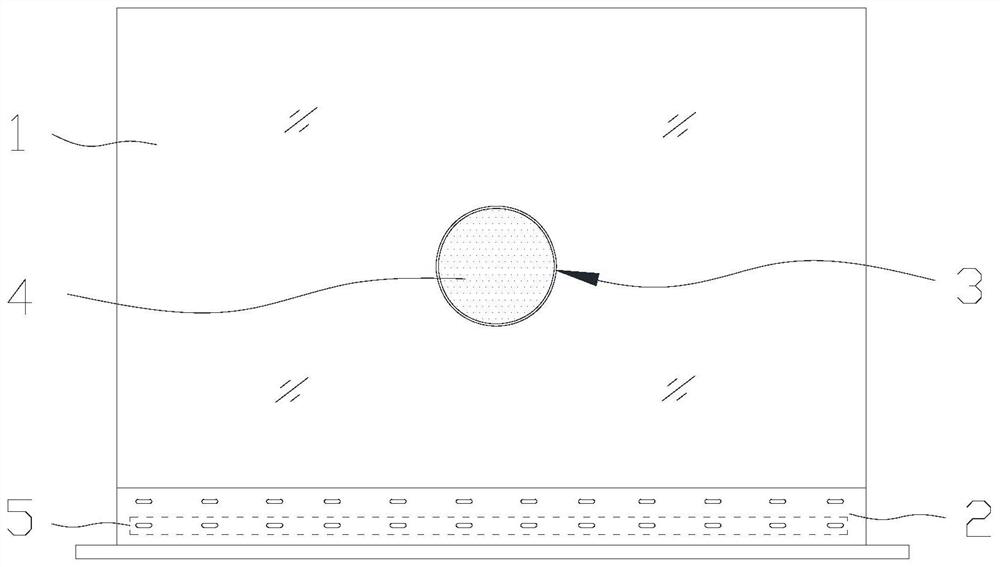

[0054] like figure 1 As shown, the explosion-proof glass plate includes a glass plate body 1 and a horizontal bar 2 connected to the lower part of the glass plate body. The material of the glass plate body 1 is toughened glass, and its thickness is 4-10 mm.

[0055] In this embodiment, the glass plate body 1 adopts a thickened tempered glass plate, which is beneficial to explosion-proof.

[0056] Among them, the explosion-proof ability of tempered glass is 3-5 times that of ordinary glass. When the tempered glass is damaged by external force, the fragments will become small particles with obtuse angles similar to honeycomb.

[0057] A through hole 3 for the arm to pa...

Embodiment 2

[0077] This embodiment 2 relates to an explosion-proof glass plate of a laboratory fume hood, except that the explosion-proof glass plate is different from the above-mentioned embodiment 1 in the following technical features, and other technical features can refer to the above-mentioned embodiment 1.

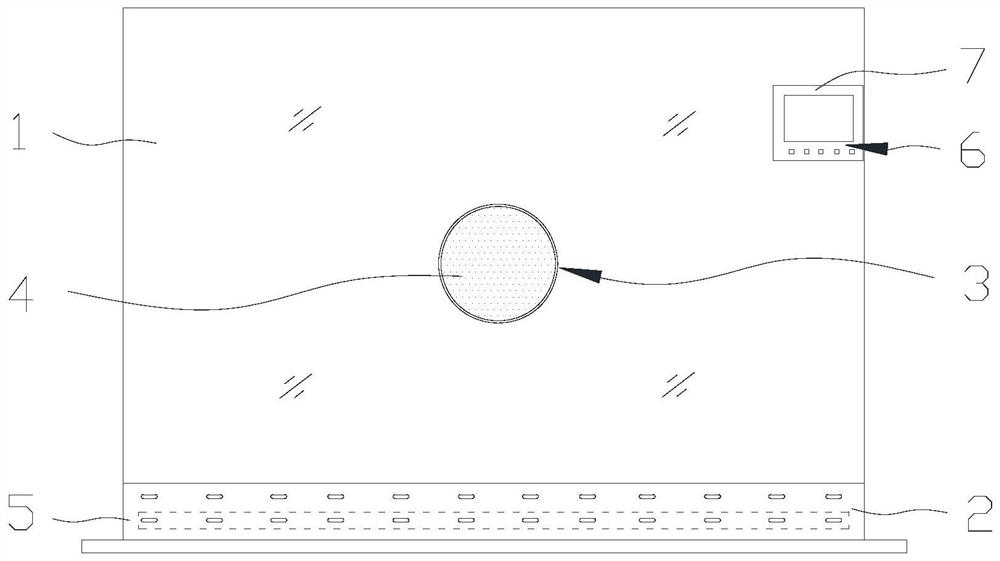

[0078] like figure 2 As shown, the explosion-proof glass plate of the laboratory fume hood mentioned in Embodiment 2 also includes a digital display temperature and humidity meter 6 with a time display function.

[0079] Wherein, the digital display temperature-hygrometer 6 is installed on the left side or the right side of the glass plate body 1 .

[0080] In this embodiment, the digital display temperature and humidity meter 6 can be installed in various ways, for example, by pasting connection, that is, the digital display temperature and humidity meter 6 is fixed on the glass plate body by strong glue, which will not be repeated here.

[0081] The digital display temperatu...

Embodiment 3

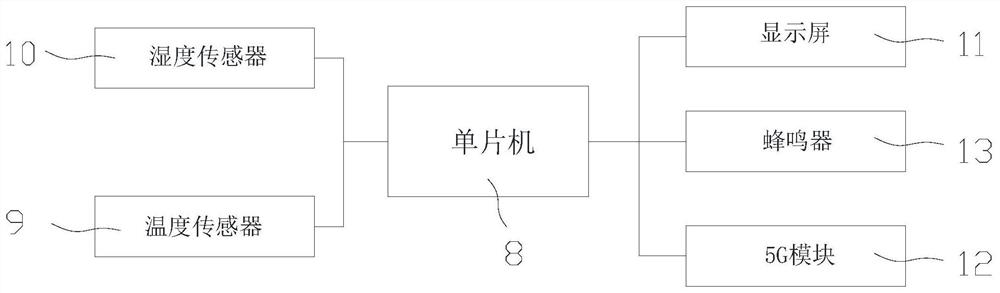

[0090] This embodiment 3 relates to an explosion-proof glass plate of a laboratory fume hood. The explosion-proof glass plate is different from the above-mentioned embodiment 2 except for the following technical features, and other technical features can refer to the above-mentioned embodiment 2.

[0091] like Figure 4 As shown, there are two through holes 3 in the present embodiment 3, and a through hole cover 4 is installed at each through hole 3, and the distance between the two through holes 3 is 40-50cm, preferably The value is 45cm.

[0092] In Embodiment 3, by designing two through holes 3, it is convenient to operate the instrument or pick and place small items through two arms during the experiment, and the operation comfort is higher.

[0093] Of course, the number of through holes 3 in this embodiment can also be reasonably set according to needs, which will not be described in detail here.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com