Three-dimensional rotary sand screening machine for flywheel production and use method of three-dimensional rotary sand screening machine

A three-dimensional, sand screening machine technology, applied in chemical instruments and methods, screening, solid separation, etc., can solve the problems of inconvenient maintenance of internal transmission parts, inability to rotate, and low adaptability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

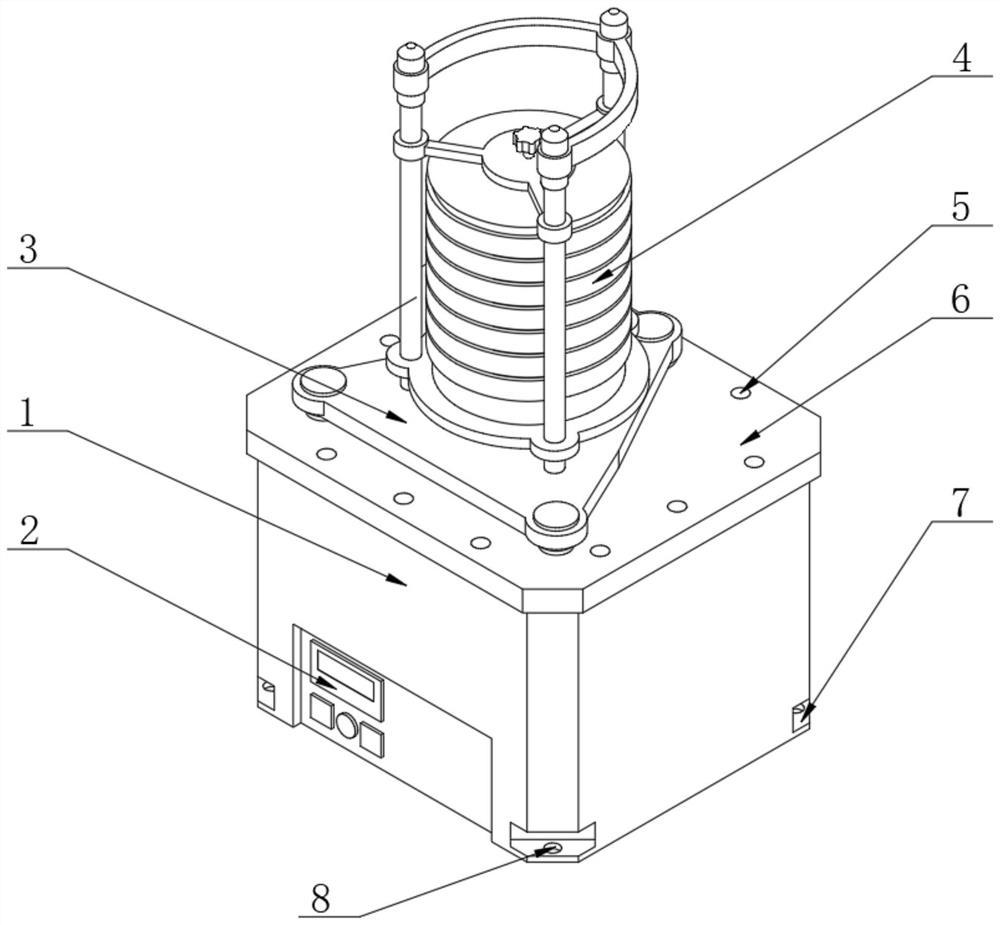

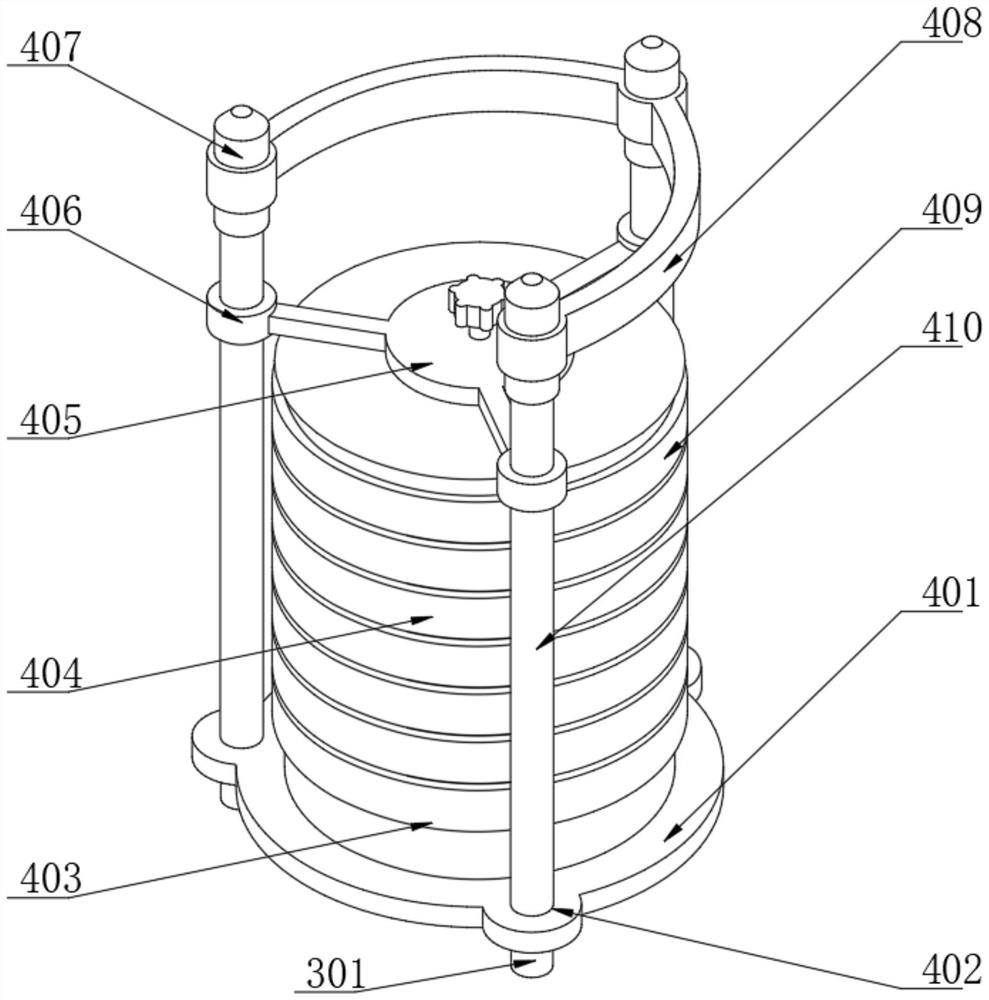

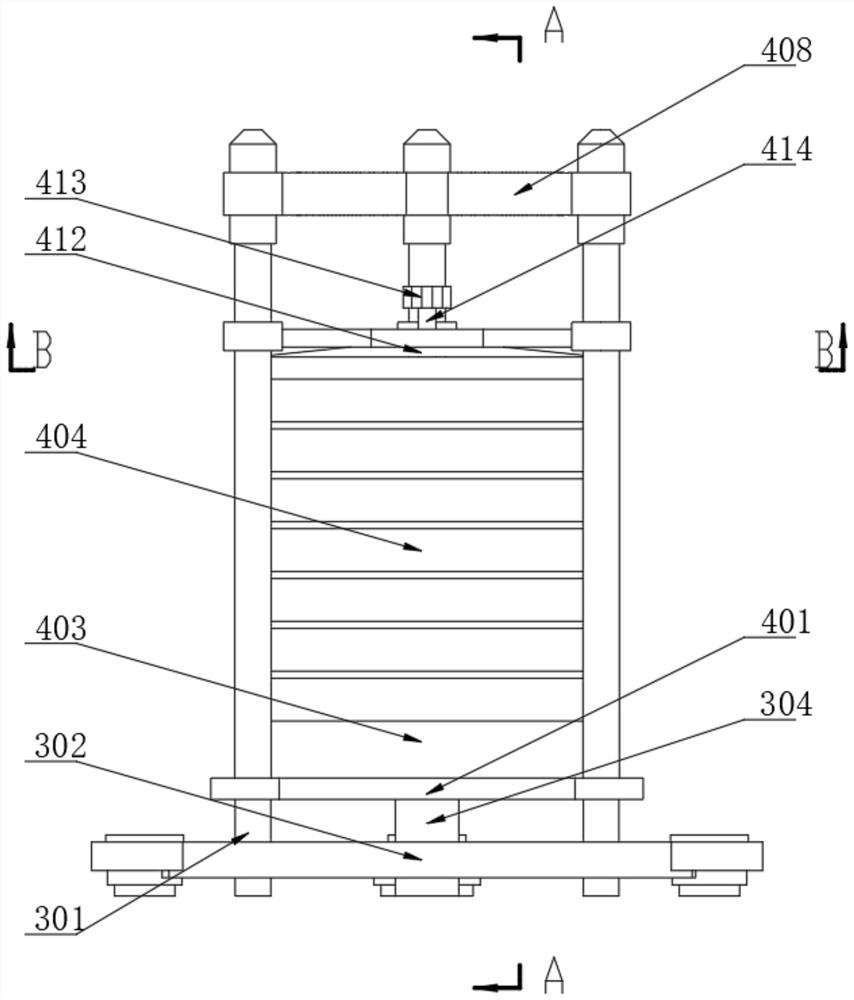

[0041] Such as Figure 1-9 As shown, a three-dimensional rotary sand screening machine for flywheel production includes an equipment base 1 and a control panel 2, a control panel 2 is fixedly installed on one side of the equipment base 1, a transmission assembly 3 is installed inside the equipment base 1, and the equipment base 1 The upper end is equipped with a protective upper cover 6, and the four sides of the protective upper cover 6 are respectively provided with docking threaded holes 5, the upper surface of the transmission assembly 3 is equipped with a sand screening assembly 4, and the four corners of the lower end of the equipment base 1 are respectively provided with installation slots 7, each installed The inside of the groove 7 is provided with a fixed installation hole 8, the inside of the equipment base 1 is provided with a transmission installation groove 307, the outer ring of the transmission installation groove 307 is provided with an upper cover matching gro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com