Preparation method of super-hydrophobic anti-static transparent coating

A transparent coating, water-resistant technology, used in coatings, conductive coatings, devices for coating liquids on surfaces, etc., can solve problems such as single function, poor dust resistance, and opaque coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

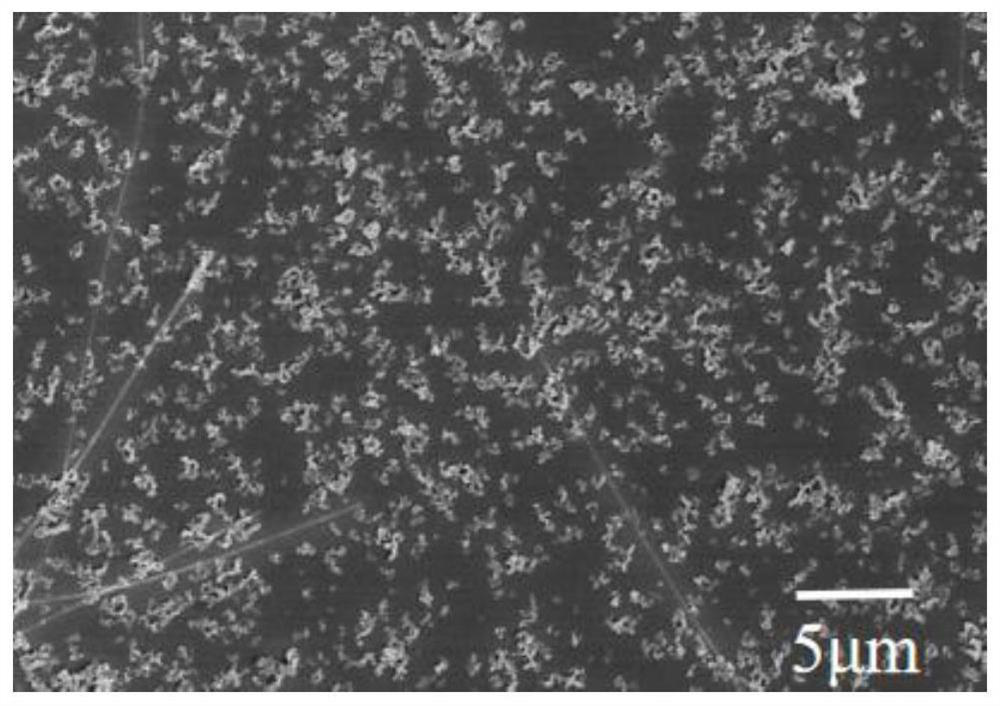

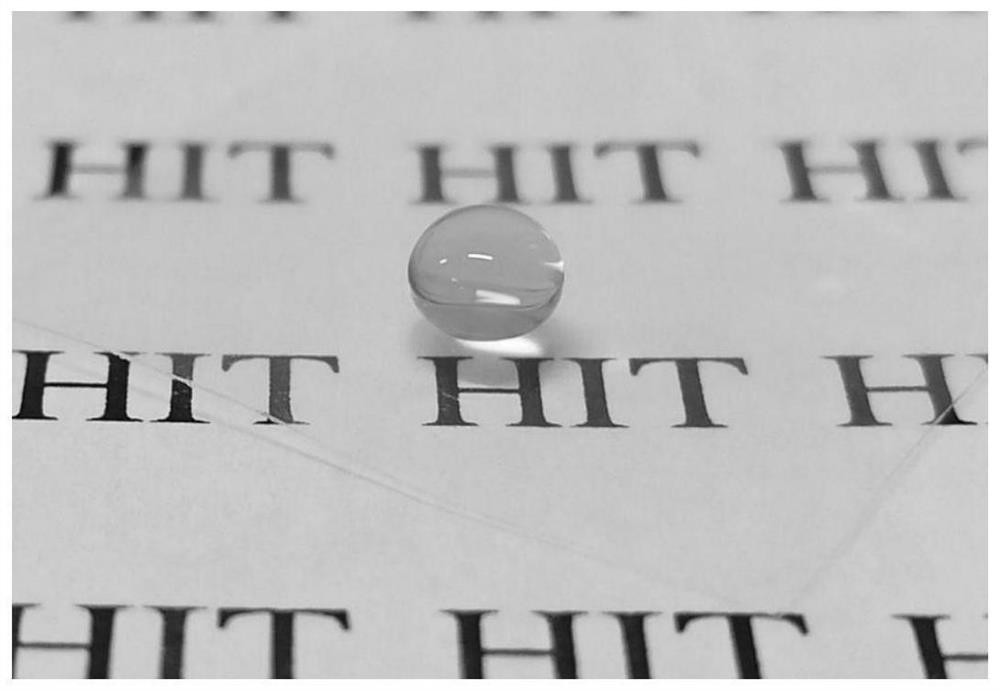

Image

Examples

Embodiment 1

[0026] Apply the coating to the surface of the polyimide film:

[0027] Step 1: Take the nano silica to add anhydrous ethanol, and the magnetic force is stirred for 15 min, the ultrasonic dispersion is 15 min to obtain a uniform nano silica dispersion, and the nano silica dispersion is placed in a container, controlling the temperature of the oil bath. It was 50 ° C, while magnetic force was stirred; orthosilicate was added, stirred for 15 min, adding hexamethylene silicane, and deionized water was added after 30min, and then the hydrophobic silica sol was obtained.

[0028] Step 2: 1 g of a hydrophobic silica sol obtained from the step, add 5 g of anhydrous ethanol, and at room temperature for 30 min, resulting in a uniform hydrophobic silica coating.

[0029] Step 3: Configure a silver nanowire solution having a concentration of 3% by weight, and dried the transparent polyimide film with ethanol. The dried transparent polyimide film was extracted into the silver nanowire solutio...

Embodiment 2

[0033] Apply the coating to the glass surface:

[0034] Step 1: Take the nano silica to add anhydrous ethanol, and the magnetic force is stirred for 15 min, the ultrasonic dispersion is 15 min to obtain a uniform nano silica dispersion, and the nano silica dispersion is placed in a container, controlling the temperature of the oil bath. It was 50 ° C, while magnetic force was stirred; orthosilicate was added, stirred for 15 min, adding hexamethylene silicane, and deionized water was added after 30min, and then the hydrophobic silica sol was obtained.

[0035] Step 2: 1 g of a hydrophobic silica sol obtained from the step, add 5 g of anhydrous ethanol, and at room temperature for 30 min, resulting in a uniform hydrophobic silica coating.

[0036] Step 3: The silver nanowire solution having a concentration of 3 wt% was configured to dry the transparent glass with acetone. The dried transparent glass was extracted into the silver nanowire solution, and the film was placed at a rate o...

Embodiment 3

[0040] Apply coating to a transparent PET surface:

[0041] Step 1: Take the nano silica to add anhydrous ethanol, and the magnetic force is stirred for 15 min, the ultrasonic dispersion is 15 min to obtain a uniform nano silica dispersion, and the nano silica dispersion is placed in a container, controlling the temperature of the oil bath. It was 50 ° C, while magnetic force was stirred; orthosilicate was added, stirred for 15 min, adding hexamethylene silicane, and deionized water was added after 30min, and then the hydrophobic silica sol was obtained.

[0042] Step 2: 1 g of a hydrophobic silica sol obtained from the step, add 5 g of anhydrous ethanol, and at room temperature for 30 min, resulting in a uniform hydrophobic silica coating.

[0043] Step 3: Configure a gold nanowire solution having a concentration of 3 wt% to dry after cleaning the transparent PET with acetone. The dried transparent PET infiltrated into the gold nanowire solution, pulled the film at a rate of 0.2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com