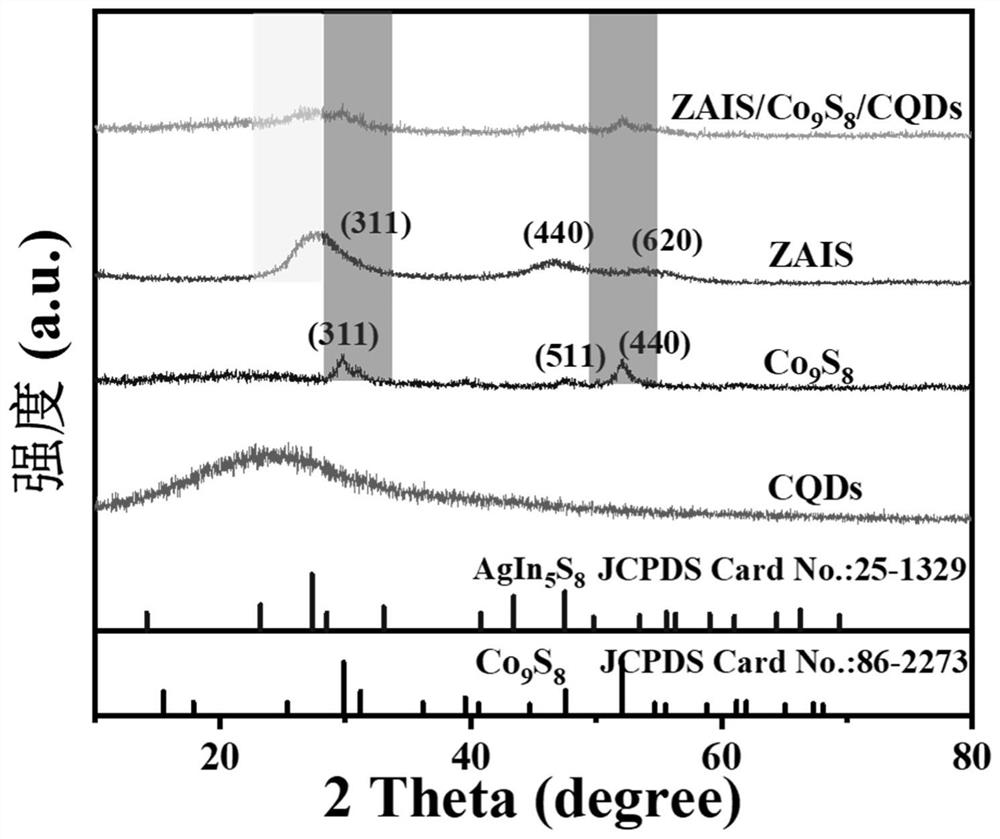

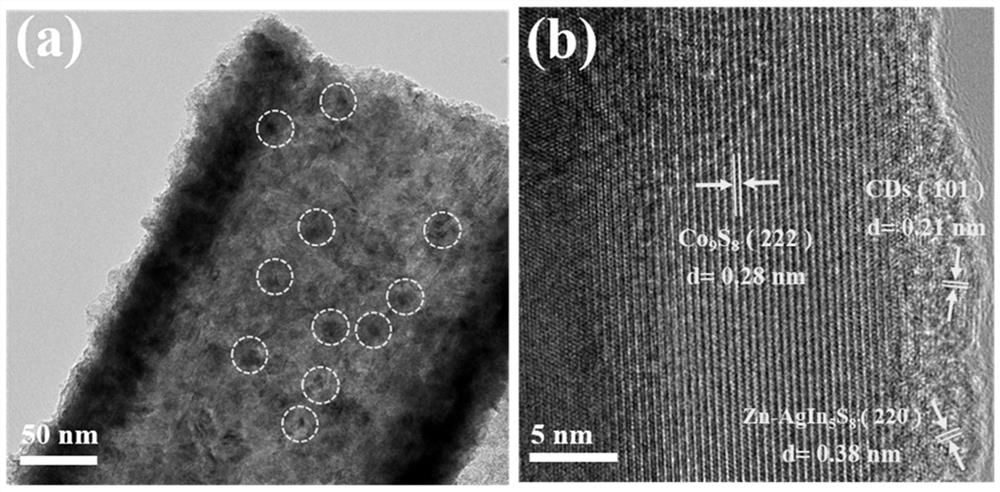

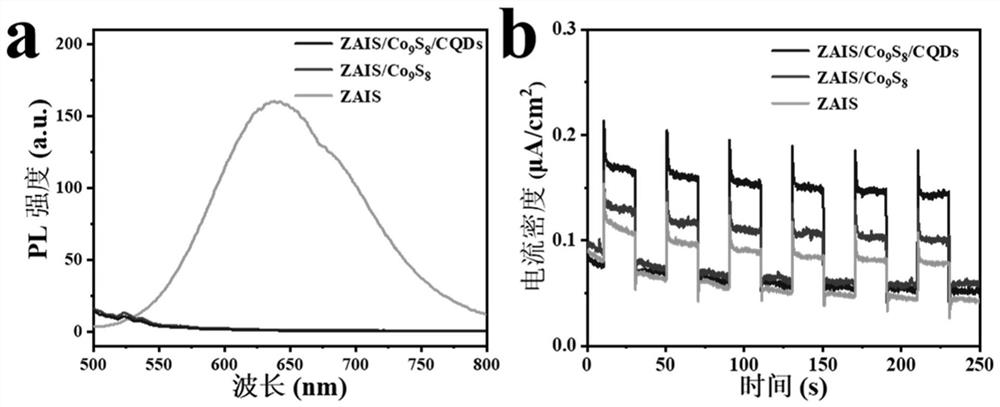

Carbon dot-assisted zn-agin 5 s 8 /co 9 s 8 Preparation method of quantum dots and application in photohydrolysis for hydrogen production

A technology of zn-agin5s8 and quantum dots, applied in catalyst activation/preparation, chemical instruments and methods, nanotechnology for materials and surface science, etc., can solve the problems of limiting photocatalytic performance, agglomeration and poor stability, and achieve Low cost, short reaction time, enhanced visible light hydrogen evolution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] A carbon dot-assisted Zn-AgIn 5 S 8 / Co 9 S 8 (ZAIS / Co 9 S 8 / CDs) preparation method of quantum dots, including the following steps:

[0025] (1) 50 mg ZAIS / Co 9 S 8 The nanocomposite was dissolved in 20 mL of deionized water, and a certain amount (0.5-4.5 mg) of carbon dot solution was added and stirred for 1 h until the solution was uniformly dispersed;

[0026] (2) The mixed solution was kept at 110 °C for 4 h, washed three times with ethanol / water to obtain ZAIS / Co 9 S 8 / CDs are kept in water.

[0027] Prepared ZAIS / Co 9 S 8 / CDs with a maximum hydrogen production rate of 3.64 mmol g -1 h -1 .

[0028] Among them, the ZAIS / Co 9 S 8 Preparation of nanocomposites: 0.1 g Zn-AgIn 5 S 8 The quantum dots were dissolved in 15 mL of deionized water, and a certain amount (1-16 mL) of Co with a concentration of 1 mg / mL was added. 9 S 8 The solution was stirred until uniformly dispersed, and freeze-dried at -30 °C for 36 h to obtain ZAIS / Co 9 S 8 Nanoc...

Embodiment 2

[0038] A carbon dot-assisted Zn-AgIn 5 S 8 / Co 9 S 8 (ZAIS / Co 9 S 8 / CDs) preparation method of quantum dots, including the following steps:

[0039] (1) 50 mg ZAIS / Co 9 S 8 The nanocomposite was dissolved in 20 mL of deionized water, and 0.5 mg of carbon dot solution was added and stirred for 1 h until the solution was uniformly dispersed;

[0040] (2) The mixed solution was kept at 110 °C for 4 h, washed three times with ethanol / water to obtain ZAIS / Co 9 S 8 / CDs are kept in water.

[0041] Prepared ZAIS / Co 9 S 8 / CDs with a maximum hydrogen production rate of 2.9 mmol g -1 h -1 .

Embodiment 3

[0043] A carbon dot-assisted Zn-AgIn 5 S 8 / Co 9 S 8 (ZAIS / Co 9 S 8 / CDs) preparation method of quantum dots, including the following steps:

[0044] (1) 50 mg ZAIS / Co 9 S 8 The nanocomposite was dissolved in 20 mL of deionized water, and 2 mg of carbon dot solution was added and stirred for 1 h until the solution was uniformly dispersed;

[0045] (2) The mixed solution was kept at 180 °C for 6 h, washed three times with ethanol / water to obtain ZAIS / Co 9 S 8 / CDs are kept in water.

[0046] Prepared ZAIS / Co 9 S 8 / CDs with a maximum hydrogen production rate of 3.06 mmol g -1 h -1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| band gap | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com