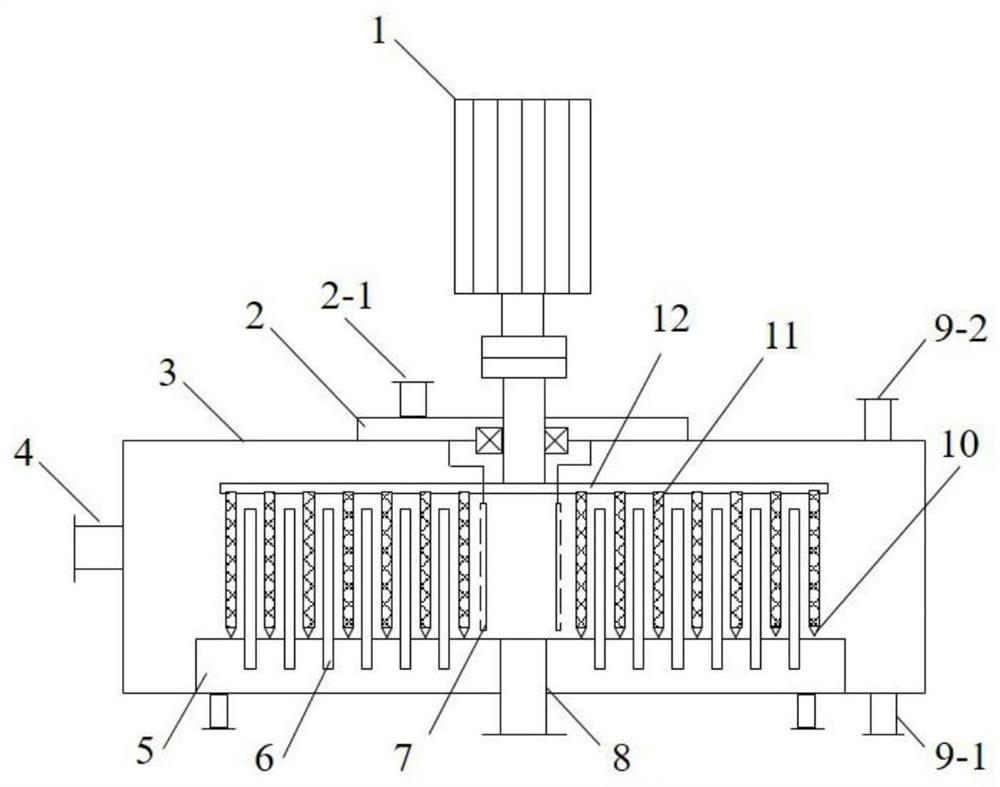

Rotary equipment for accurate temperature control of thermosensitive substance and application method

A technology of rotating equipment and substances, applied in chemical instruments and methods, chemical/physical processes, chemical/physical/physical chemical processes, etc., can solve problems such as inability to accurately control the temperature of heat-sensitive materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

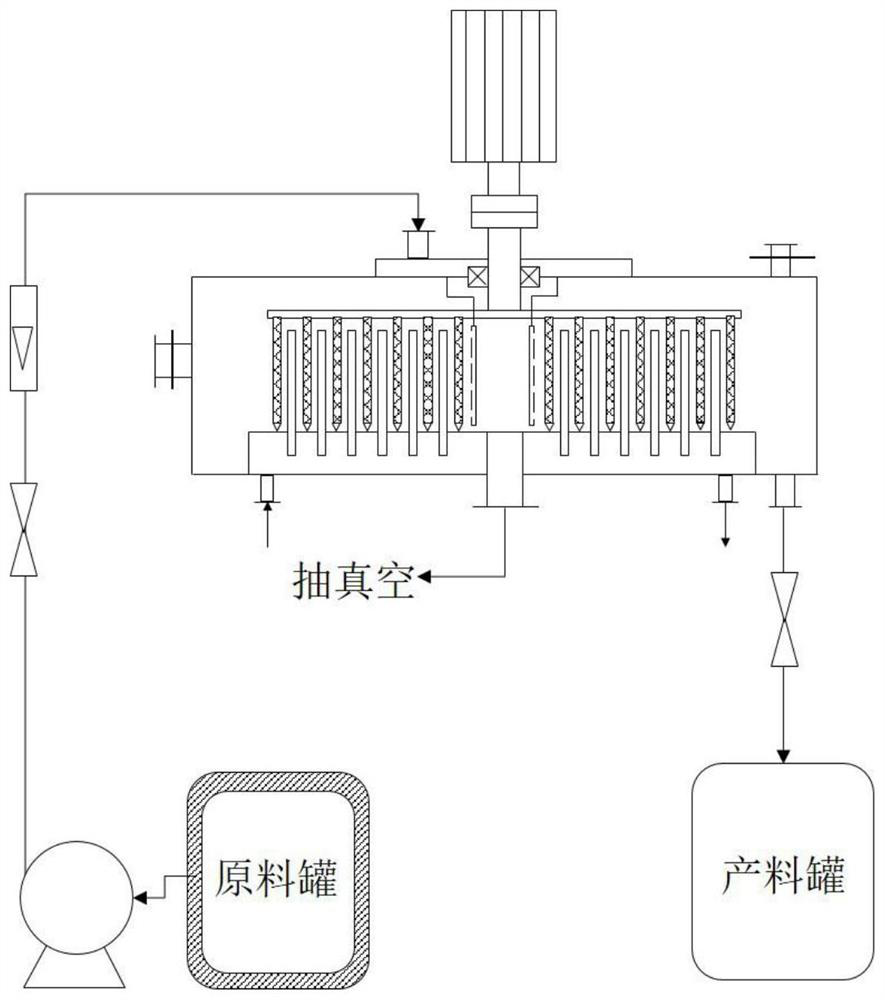

[0084] Such as figure 2 As shown, this device is used to remove the volatile TDI in the polyurethane prepolymer. The experimental conditions are as follows: the rotational speed of the rotating bed is 200-2000r / min, the volume flow rate of the material is 50L / h, and the devolatilization temperature is 100°C (the boiling point of TDI in vacuum is about 100°C, and the temperature of the material is higher than 110°C and it is easy to oxidize. Yellow, and form foaming), through the use of water / stainless steel gravity heat pipe can accurately control the temperature of the material 100 ℃. The vacuum degree in the rotating bed is 0.099MPa, and the viscosity of the material is about 1Pa·s. The TDI content in the polyurethane prepolymer before and after devolatilization is detected by gas chromatography. At the speed of 2000r / min, this device realizes the removal of 80% of the TDI content in the polyurethane prepolymer in one pass, and the final TDI content is 800-1200ppm , At ...

Embodiment 2

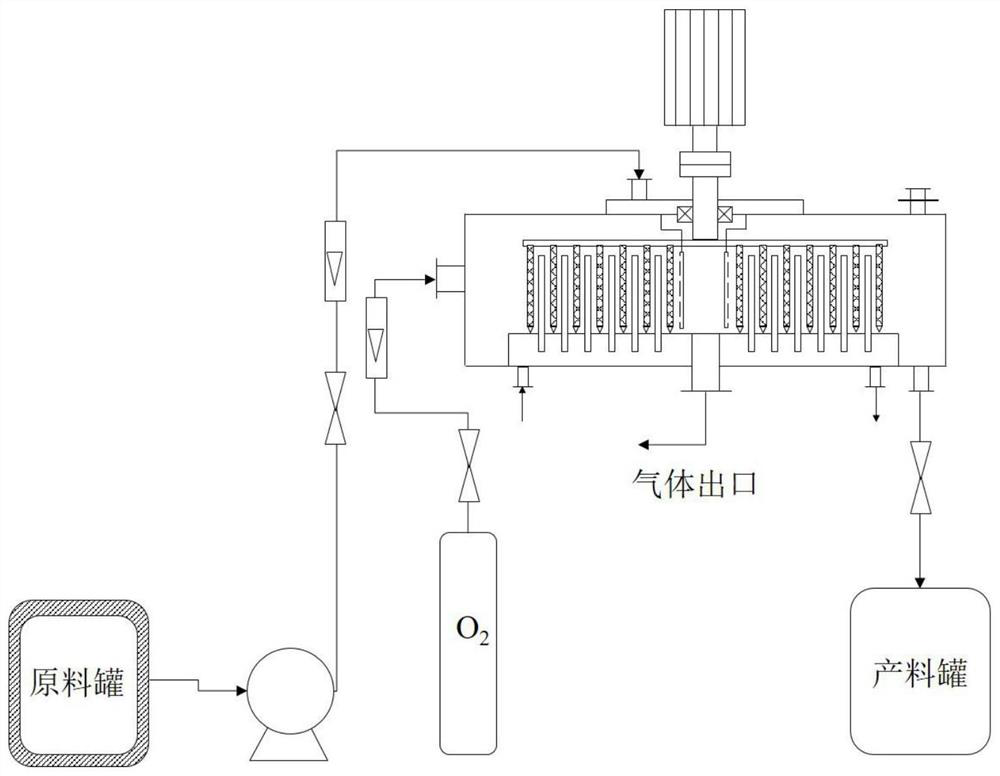

[0086] Such as figure 2 As shown, the fermentation process of hyaluronic acid was studied using the rotating equipment designed in the patent. The strain was provided by the Department of Biochemical Engineering of Beijing University of Chemical Technology, and it was obtained by mutagenesis of Streptococcus zooepidemicus (it will be inactivated when it exceeds 80°C). By adopting water / stainless steel gravity heat pipe and changing the absolute pressure inside the heat pipe, the boiling point of water is controlled to be 75°C. The effects of rotational speed, temperature, pH value, aeration volume, and initial sugar concentration on the fermentation process were studied. It can be determined that the best operating conditions for the production of hyaluronic acid by fermentation are the rotational speed of 1500r / min, the temperature of 60°C, the initial sucrose concentration of 6%, and the gas volume of 1.2m 3 / h, the pH is within the range of 6.8-7.2, the fermentation perio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com