Refining and purifying process and refining, purifying and mixing equipment for glycerol glucoside

A glucoside, refining and purification technology, applied in the field of glycerol glucoside, can solve the problems of simple mixing structure, lower mixed fermentation efficiency of glycerol glucoside, stirring uniformity, and lack of circulation mixing effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

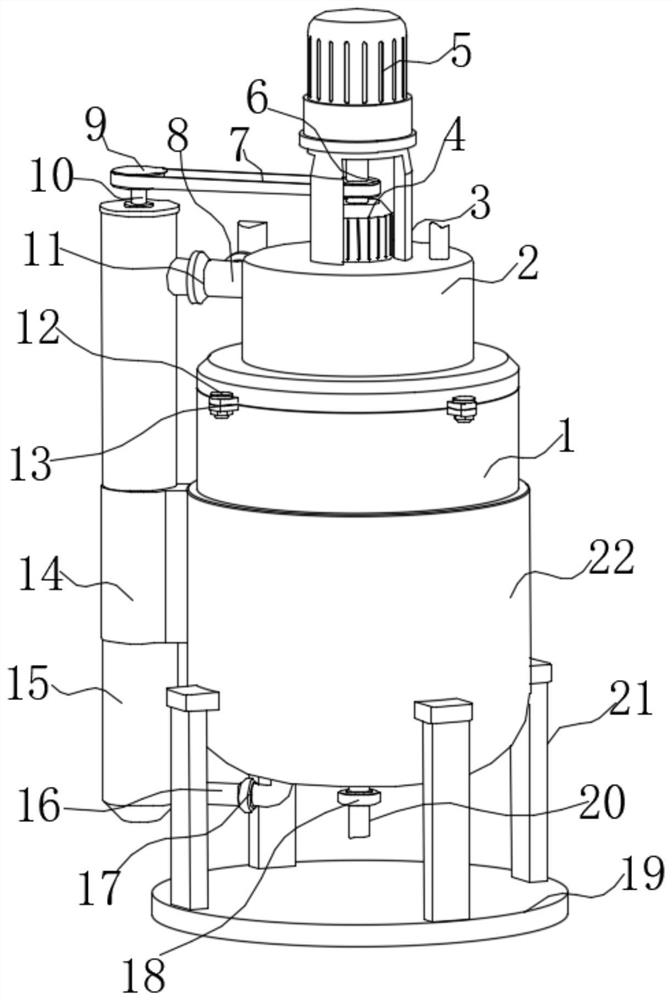

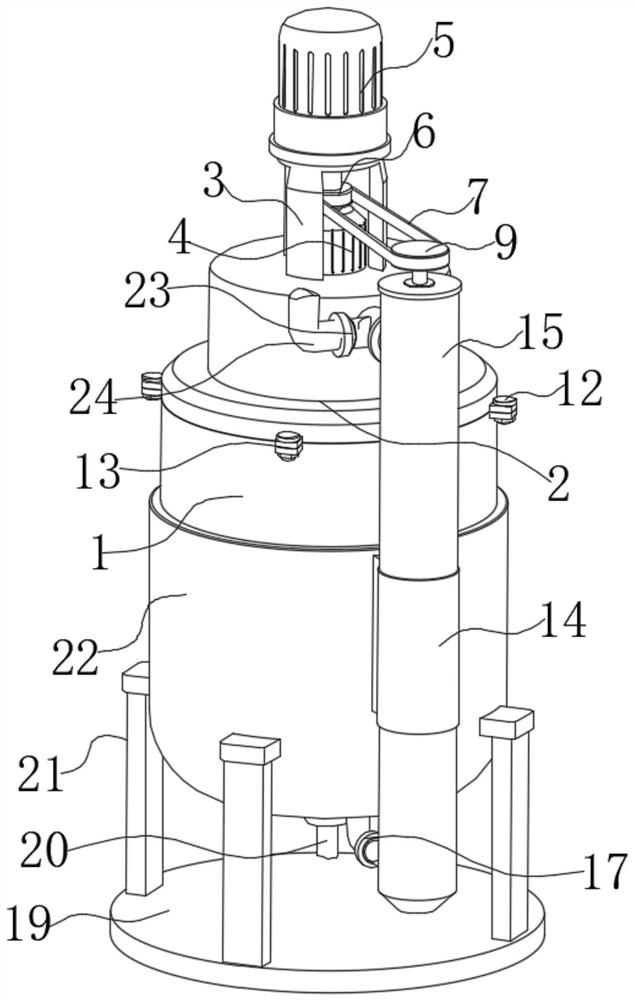

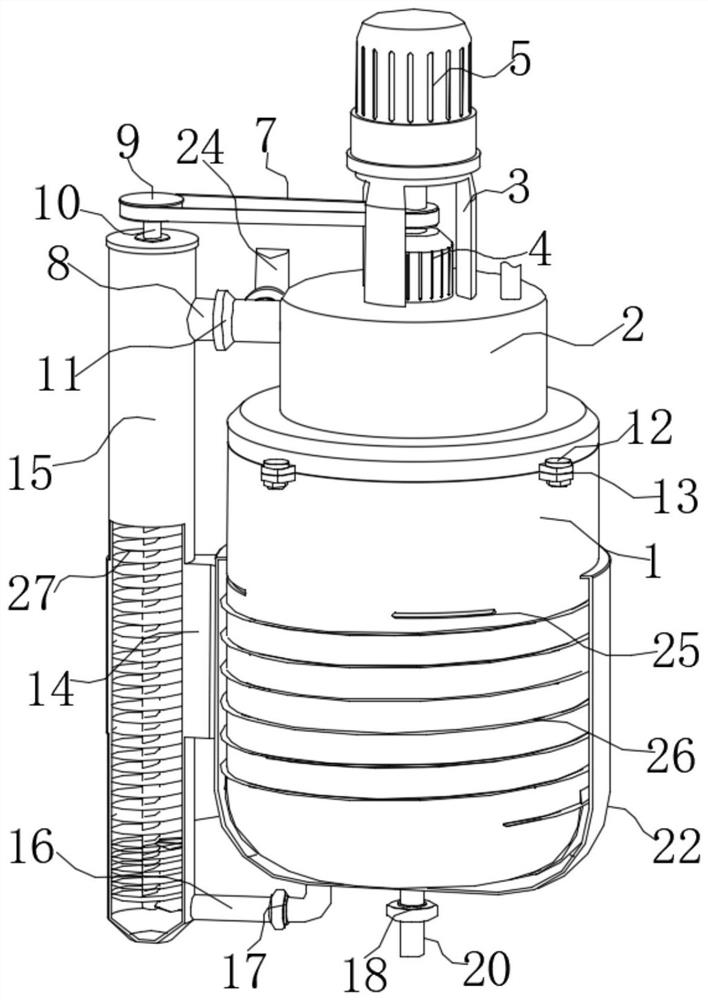

[0040] Such as Figure 1-Figure 9 A refinement and purification process and mixing equipment for glycerol glucoside shown, including a kettle body 1 and a kettle cover 2, the kettle body 1 and the kettle cover 2 are sealed and connected by multiple installation structures, and the installation structure includes two fixed installations respectively The kettle body 1 and the kettle cover 2 are close to the fixed ear 13 on the outside of one end port, and the two fixed ears 13 are fixedly connected by the locking member 12. The middle position of the bottom of the kettle body 1 is provided with a discharge structure, and the top of the kettle cover 2 A sterile air inlet pipe is connected and installed, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com