Tableware cleaning device

A tableware cleaning and sorting device technology, which is applied in cleaning devices, household cleaning devices, tableware washing machines/rinsing machines, etc., can solve the problems of unstable sanitary quality of tableware (drinking), difficult control of boiler discharge, and sewage discharge. Difficult to deal with

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

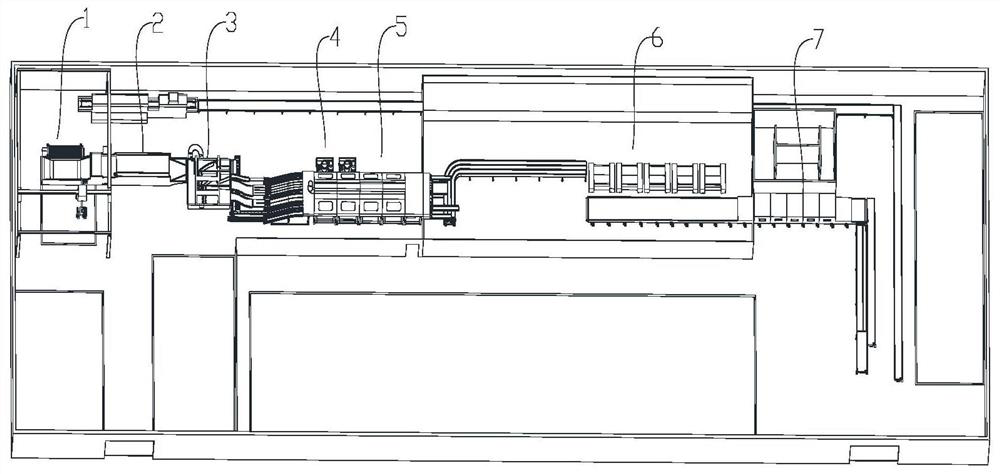

[0043] Such as figure 1 As shown, the present embodiment provides a tableware cleaning device, including a slag removal device 1, a sorting device 3, a water knife cleaning device 4, an air knife dewatering device 5, a packaging device 6 and a sterilizing device 7 arranged in sequence. The adjacent two are connected through the first transmission component.

[0044] In this embodiment, a tableware cleaning device includes a slag removal device 1, a sorting device 3, a water knife cleaning device 4, an air knife dewatering device 5, a packaging device 6 and a sterilization device 7 arranged in sequence, two adjacent The tableware is connected through the first transmission component, and the tableware is sequentially removed by the slag removal device 1, and the sorting device 3 is used for accurate sorting. The water knife cleaning device 4 uses a high-pressure water knife to clean the surface of the tableware. 5 acts on the surface of the tableware to scrape off the moisture...

Embodiment 2

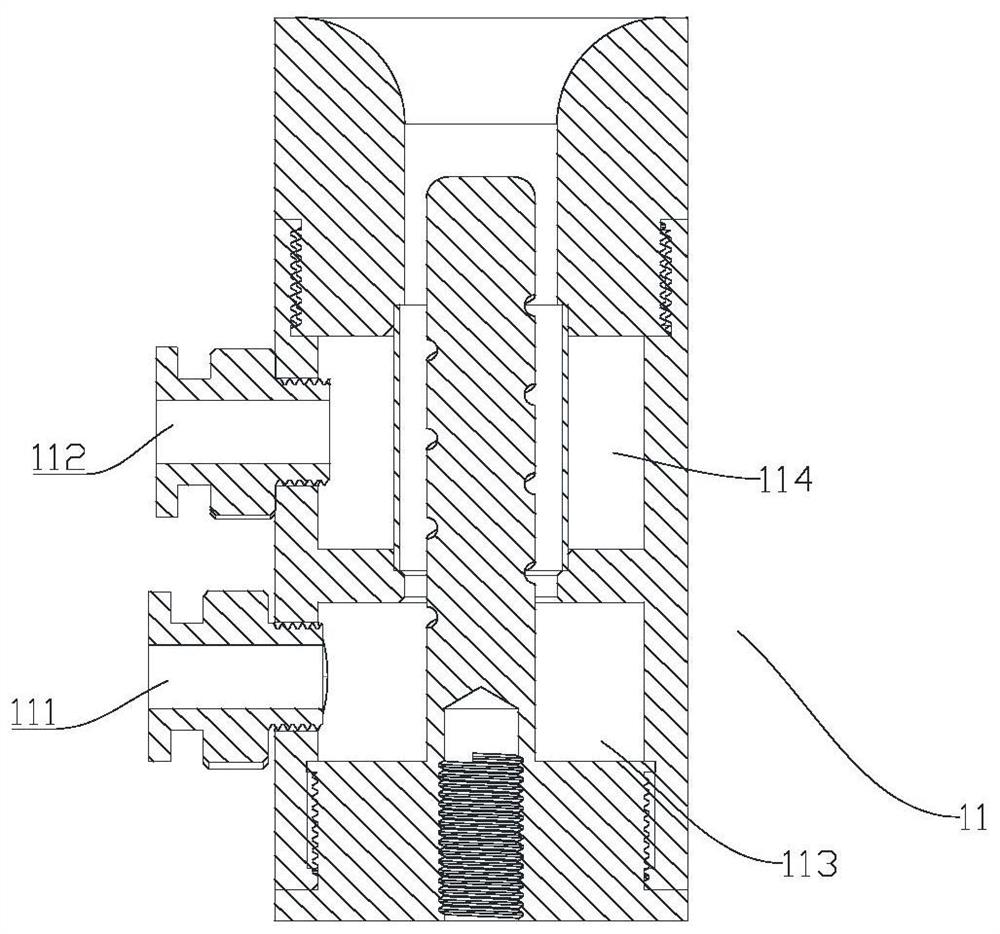

[0046] Such as figure 1 As shown, this embodiment is based on Embodiment 1. The slag removal device 1 includes an air intake assembly and a high-speed water outlet assembly that cuts the gas ejected from the intake assembly.

[0047] In this embodiment, the slag removal device 1 includes an air inlet assembly and a high-speed water outlet assembly that cuts the gas ejected from the air inlet assembly, that is, the direction in which the gas is ejected from the air inlet assembly intersects with the water outlet direction of the above-mentioned high-speed water outlet assembly, The high-speed water outlet component uses high-speed water flow to cut the gas ejected from the intake component into micro-bubbles with a diameter of less than 0.05mm and rise from the bottom of the pool to the water surface. The small bubbles rise slowly and pass through food residues, paper towels and some sundries with a small specific gravity It is easy to absorb on the surface of sundries and betw...

Embodiment 3

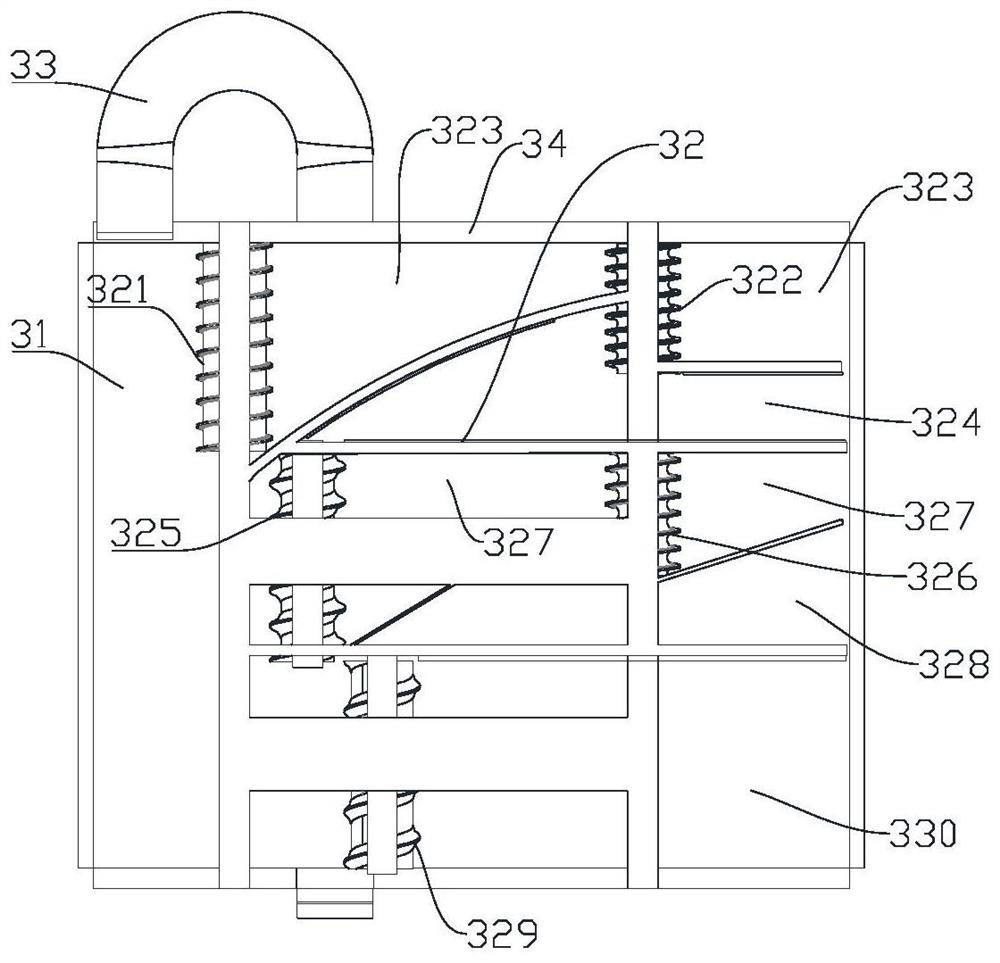

[0057] Such as image 3 , 4 As shown, in this embodiment, on the basis of some of the above-mentioned embodiments, the above-mentioned sorting device 3 includes a second conveying assembly 31 and a sorting assembly 32, and the above-mentioned sorting assembly 32 includes a first sorting assembly 32, and the above-mentioned first sorting assembly The assembly 32 includes a first sorting passage 323 and a first sorting piece 321 arranged on the front side of the first sorting passage 323, and the first sorting piece 321 and the first sorting passage 323 are arranged on the second conveyor. On the upper side of the assembly 31, the first sorting member 321 is provided with a first sorting slot 3211 for sorting tableware.

[0058] In this embodiment, the above-mentioned sorting device 3 includes a conveying assembly and a sorting assembly 32, and the above-mentioned sorting assembly 32 includes a first sorting assembly 32, and the above-mentioned first sorting assembly 32 include...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com