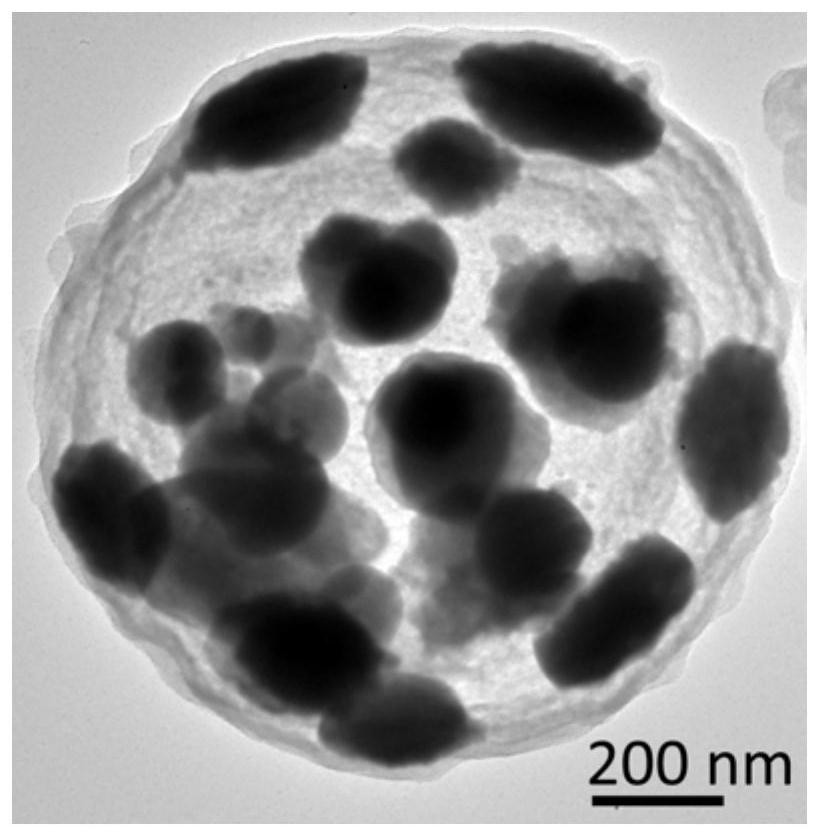

A multi-core multi-shell hollow material encapsulating nanoparticles and its preparation method and application

A nanoparticle and metal nanoparticle technology, applied in the field of multi-core multi-shell hollow materials and their preparation, can solve the problems of short cycle life, low energy density, poor rate performance, etc., achieve good cycle stability and increase volume Effects of Capacity Density and High Energy Density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0079] The present invention provides a method for preparing a multi-core multi-shell hollow material encapsulating nanoparticles, the method comprising:

[0080] (a) The aqueous carbon source solution with a concentration of 0.1-6M is loaded into a hydrothermal reactor at 175-220 °C for 100-180 min, naturally cooled and filtered, and after 2-5 washes, the product is dried at 60-100 °C for 6-24 h to obtain a carbon sphere template;

[0081] (b) The carbon sphere template obtained in step (a) is dispersed in a metal salt solution at a concentration of 0.1-5 M to give the suspension. Wherein the metal salt solution is a combination of tin tetrachloride solution, stannous chloride solution, stannous sulfate solution, tin oxalate solution, stannous oxalate solution and stannous acetate solution, insulation adsorption at 20-60 ° C for 1-48h, the adsorbed mixture is filtered, washed with deionized water, methanol or ethanol for 2-5 times, dried at 60-100 ° C for 6-24h to obtain a solid p...

Embodiment 1

[0087] Preparation method for encapsulating nanoparticles multi-core multi-shell hollow material, the method comprising:

[0088] (1) The aqueous sucrose solution with a concentration of 1.5M was loaded into a reaction kettle at 200 °C for 135 min, naturally cooled and filtered, and washed 3 times by water, 3 times by ethanol, and the product was placed in a 60 °C oven to dry for 24 h to obtain a carbon sphere template with a diameter of 2.9 μm;

[0089] (2) Disperse 1 g of the carbon bulb template obtained in step (1) with 40 mL of SnCl at a concentration of 0.5 M 4 In the solution, ultrasonically disperse the carbon balls evenly, load them into a beaker, place them in a 40 °C water bath for 4h, filter the adsorbed water, wash it 3 times with deionized water, wash it three times with ethanol and then put it into a 60 °C oven to dry for 24h to obtain a solid precursor;

[0090] (3) The solid precursor obtained in step (2) is placed in a muffle furnace, heated to 550 °C at 2 °C / min...

Embodiment 2

[0095] Preparation method for encapsulating nanoparticles multi-core multi-shell hollow material, the method comprising:

[0096] (1) The aqueous sucrose solution with a concentration of 2.5M was loaded into a reactor at 180 °C for hydrothermal reaction for 150 min, naturally cooled and filtered, and washed 3 times by water, 3 times by ethanol, and the product was placed in a 60 °C oven to dry for 24 h to obtain a carbon pellet template with a diameter of 2.7 μm;

[0097] (2) Disperse 1 g of the carbon bulb template obtained in step (1) with 40 mL of SnCl at a concentration of 0.5 M 2 In the solution, the carbon balls are dispersed evenly by ultrasound, loaded into a beaker, placed in a 30 °C water bath for 6h, the adsorbed pumping filter, washed 3 times with deionized water, and the ethanol washed three times into a 60 °C oven to dry for 24 h to obtain a solid precursor;

[0098] (3) The solid precursor obtained in step (2) is placed in a muffle furnace, heated to 550 °C at 5 °C / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com