Low-load period heat supply steam pressure adjusting method and device, controller and medium

A pressure regulation, low-load technology, applied in the direction of fluid pressure control, electric fluid pressure control, control/regulation system, etc., can solve the problem that the extraction steam parameters are difficult to ensure the user's heating demand, and can not meet the industrial steam and other problems , to achieve the effect of improving flexibility, ensuring heating demand and improving economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

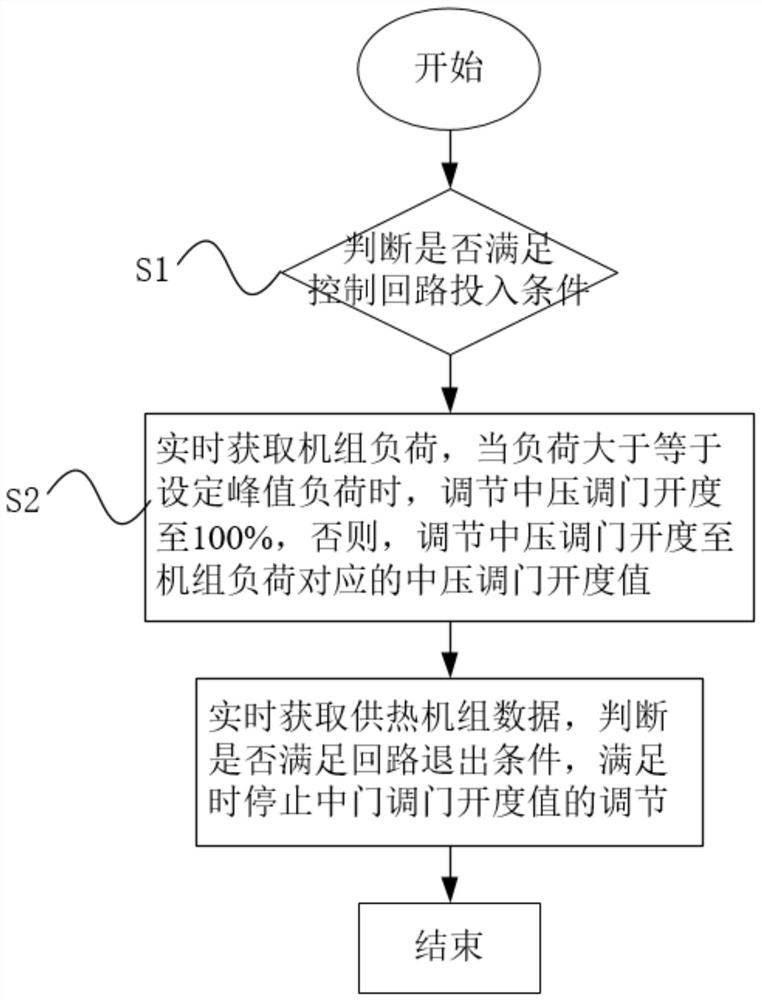

Method used

Image

Examples

Embodiment

[0033] A method for adjusting the pressure of heating steam during low-load periods. This embodiment takes a N325-16.18 / 535 / 535 subcritical parameter, one intermediate reheat, four-cylinder four-exhaust, single-shaft, condensing steam turbine as an example, This steam turbine is equipped with 2 high-pressure main steam valves, 8 high-pressure regulating valves, and 4 medium-pressure regulating valves.

[0034] When the present invention is implemented, firstly, the opening value of the medium-voltage valve corresponding to the load of the unit is obtained through the adjustment test of the medium-voltage valve in the low-load section. The steps of the middle door pressure adjustment adjustment test in the low load section include: setting the test load area, stabilizing the high discharge pressure at the preset test pressure value, adjusting the load of the unit in the test load area, and obtaining the corresponding values of different unit loads. Medium voltage adjustable d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com