Preparation and pasting method of optical fiber sensor for measuring outer curvature of columnar material

A technology of optical fiber sensor and external curvature, which is applied in the direction of cladding optical fiber, measuring devices, instruments, etc., can solve the problems of insufficient reliability and stability, and achieve the effect of improving transmission rate, stable wavelength, and small restoring force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] Among production method of the present invention, the fiber Bragg grating should be integrated coating material, the grating gauge (sensing gauge) two key factors for production and selection. Further, the fiber coating should be high temperature, such as a polyimide coating layer (300 ℃ resistant to high temperature), so as to ensure the production of the sensor, during use, the coating layer of the optical fiber from damage; the gauge FBG sensor should be as small (10mm inside), smaller gauge sensor embedded in the substrate, can ensure maximum recovery force sensing small region of the grating, to ensure maximum sensing area with a grating film base changes together. Integrated base material should: hardness, resilience, shrinkage, color, cost, and obtained a manner, manufacturing conditions these factors into selected.

[0037] Substrate material should have suitable hardness (about 50HA), the tensile distortion is not deformed repeatedly, tearing, able to bend along wi...

Embodiment

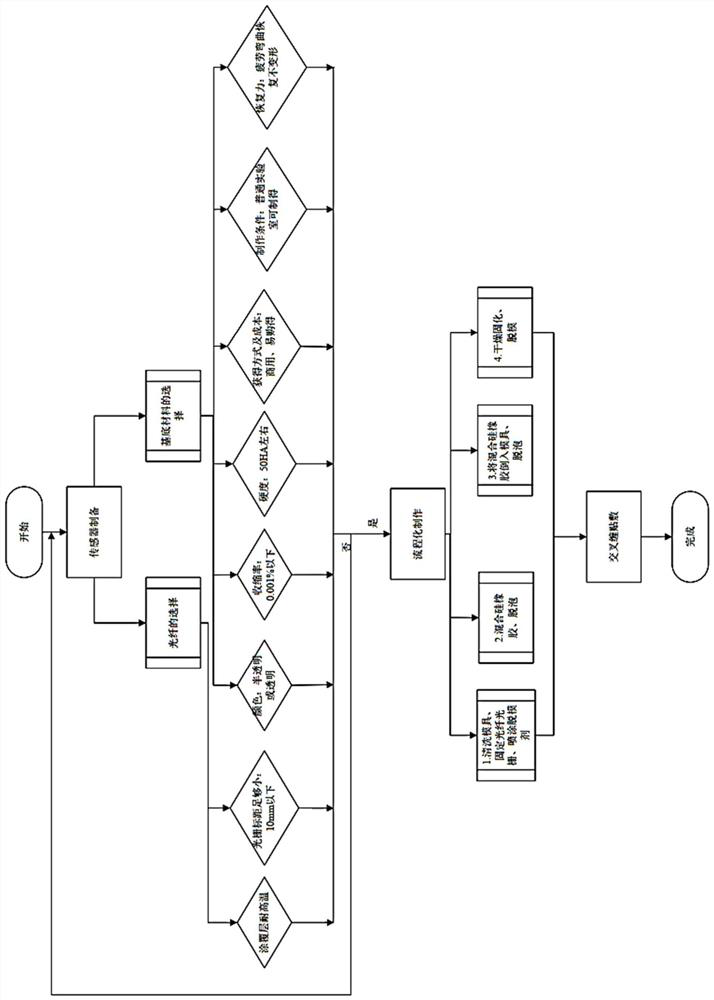

[0043] See figure 1 Preparation method of the present invention an optical fiber sensor, the optical fiber and the first choice of the substrate material; fiber Bragg grating of the present embodiment selects a company making, sensing gauge of 10mm, a polyimide coating material, the working temperature range of -30 ℃ -300 ℃, a core diameter of 0.1mm. Select a type of commercial silicone rubber, and the performance parameters are in line with commercial silicon rubber figure 1 Among flowchart of color, shrinkage, hardness, way to obtain and cost, production conditions, required recovery force. The liquid silicone rubber into A, B two components. In use, the A, B two proportions to classification.

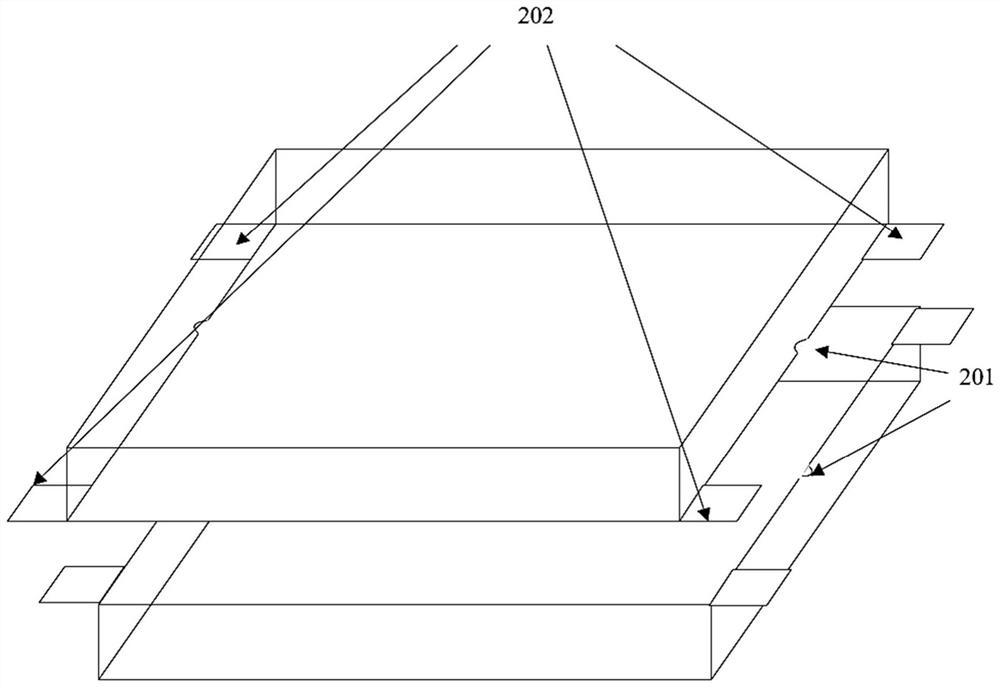

[0044] use figure 2 Aluminum mold shown, the mold is divided into two parts, up and down without the cover, only four sides, parallel to the fiber delamination stopper 201 holes, the total diameter of the optical fiber parallel limiting hole 1mm, 202 at the four corners of a bolt connect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| Sensitivity | aaaaa | aaaaa |

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com