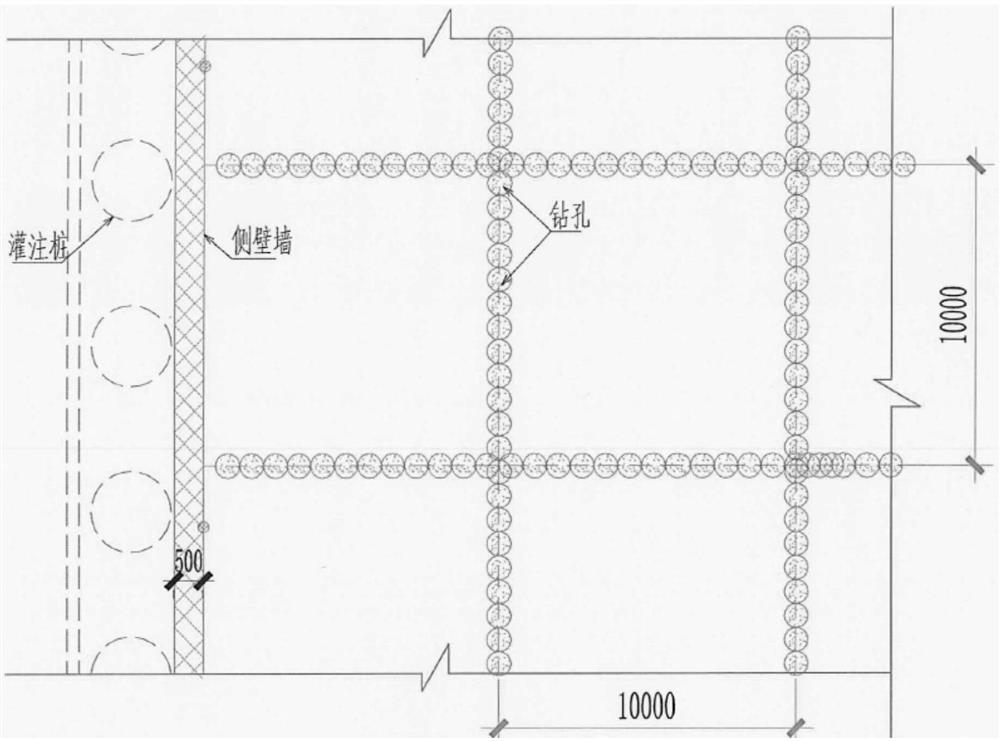

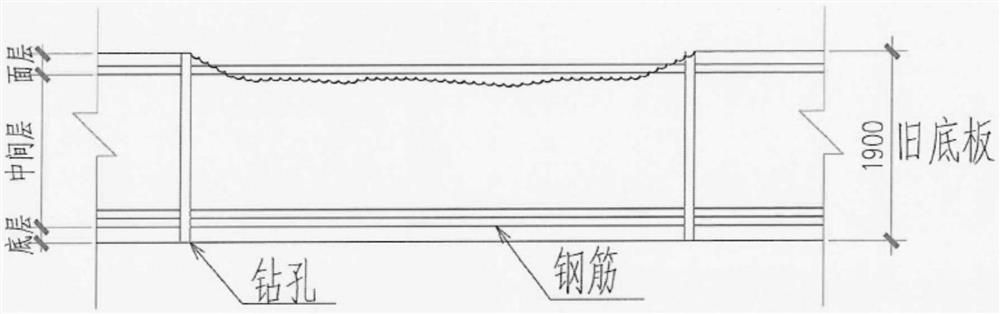

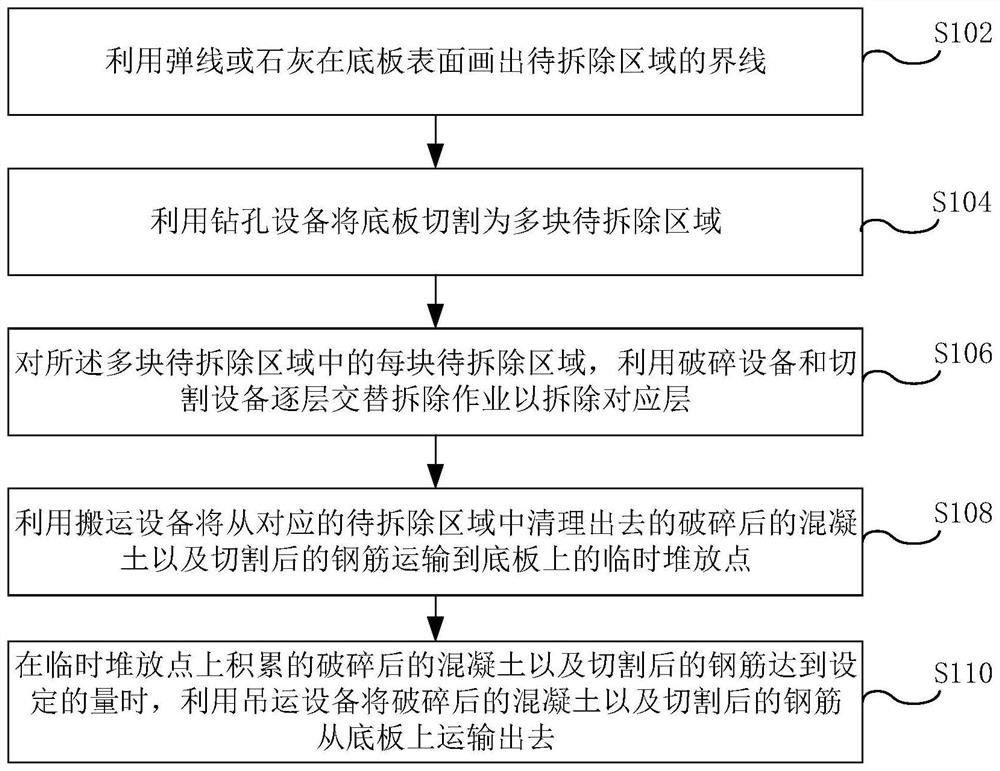

Dismantling method for bottom plate in foundation pit supporting structure

A technology for foundation pit support and bottom plate, which is applied in infrastructure engineering, excavation, construction, etc., can solve the problems of thick bottom plate, easy to wear gun heads, low demolition efficiency, etc., to reduce difficulty, speed up demolition progress, and improve demolition. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] This part will describe the specific embodiment of the present invention in detail, and the preferred embodiment of the present invention is shown in the accompanying drawings. Each technical feature and overall technical solution of the invention, but it should not be understood as a limitation on the protection scope of the present invention.

[0038] In order to facilitate the understanding of the present invention, it is necessary to explain the technical terms involved in the embodiments of the present invention.

[0039] Breaking pick is a tool for construction engineering. It is suitable for many kinds of excavation, shoveling and chiseling to destroy solid fields, such as construction, road construction, electric power, telecommunications, cables, trenching and pre-buried crushing work. Up to 1300 times / min. In this embodiment, the breaker can be a HRB-90 hydraulic breaker, which weighs 28 kg and is convenient for one person to operate.

[0040] The electric h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com