Adhesive for wet paving of macromolecular self-adhesive film waterproof coiled material and preparation method of adhesive

A technology of self-adhesive film and waterproof membrane, which is applied in the field of waterproof materials, can solve the problems of easy cracking of adhesives, and achieve the effects of prolonging service life, low overall cost and good bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] This patent also discloses a preparation method of an adhesive for wet-laying of polymer self-adhesive film waterproof coiled material, which is characterized in that it includes the following steps: preparing raw materials according to the weight ratio; adding each raw material into a stirring tank for stirring and mixing ; Finishing after discharge.

[0036] Specifically, the product is prepared and tested through the following several examples, and the performance test results of the products obtained in each embodiment and comparative example are as follows: Figure 9 shown.

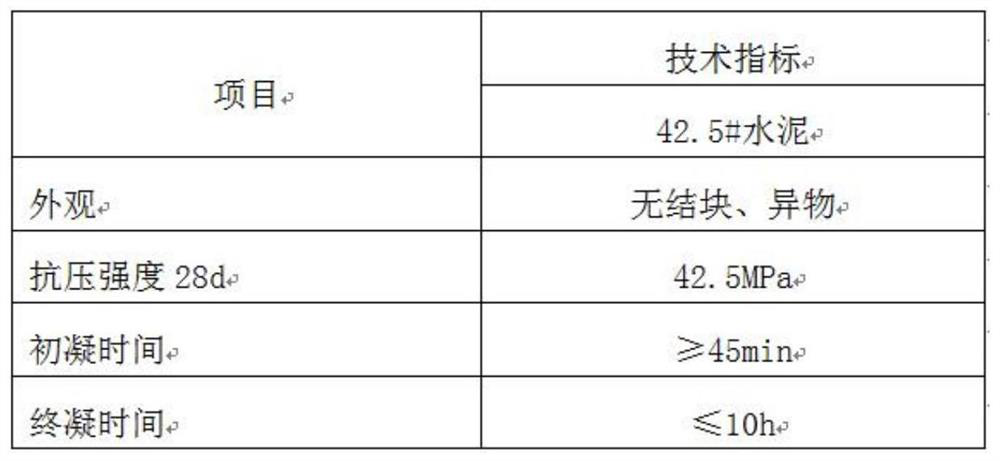

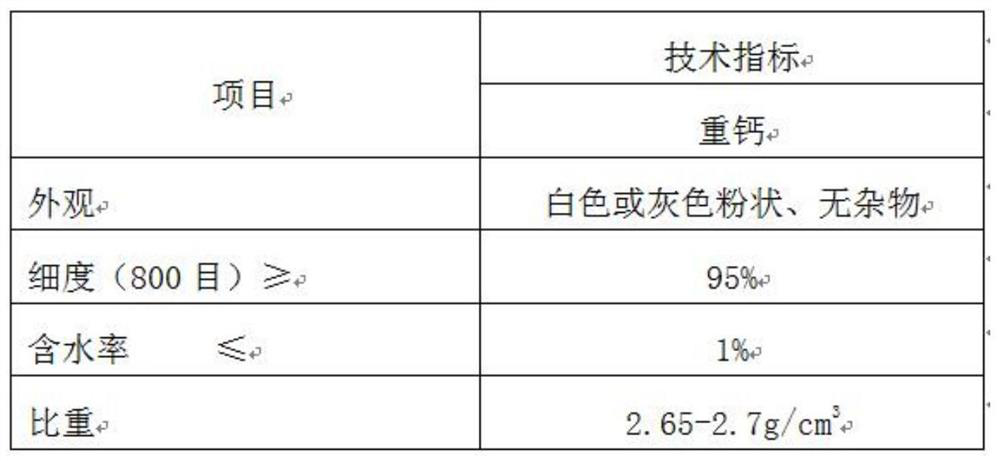

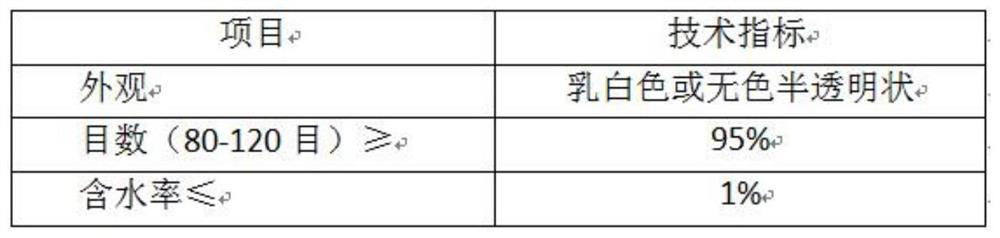

Embodiment 1

[0037] Example 1: 50 parts of cement, 15 parts of heavy calcium, 35 parts of fly ash, 60 parts of polyvinyl alcohol, 4 parts of water-retaining agent, 10 parts of quartz sand, 20 parts of masterbatch, and 6 parts of thickener were measured and added Mix and stir in a mixing tank, and the stirring time is 30min-40min to fully mix and stir evenly to obtain an adhesive for wet-laying of polymer self-adhesive film waterproof membranes.

Embodiment 2

[0038] Example 2: 55 parts of cement, 20 parts of heavy calcium, 40 parts of fly ash, 62 parts of polyvinyl alcohol, 6 parts of water-retaining agent, 15 parts of quartz sand, 22 parts of masterbatch, and 8 parts of thickener were measured and added Mix and stir in a mixing tank, and the stirring time is 30min-40min to fully mix and stir evenly to obtain an adhesive for wet-laying of polymer self-adhesive film waterproof membranes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com