Method and system for determining thermal management parameters of power battery based on low-temperature fast charging

A battery system and power battery technology, applied in battery/fuel cell control devices, electric vehicles, transportation and packaging, etc., can solve problems affecting user experience, prolong charging time, battery system consumption, etc., to avoid charging power limit, The effect of correct logic and reduced power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

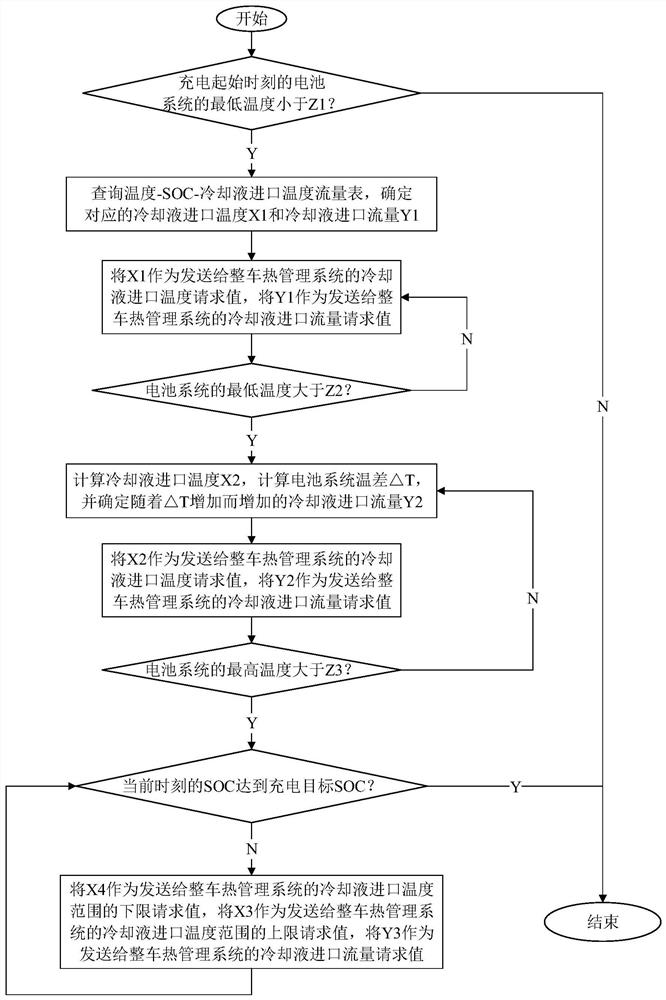

[0018] Such as figure 1 As shown, the method for determining the thermal management parameters of the power battery based on low-temperature fast charging in this embodiment is performed by the battery management system (ie, BMS), and the determination method includes:

[0019] The first step is to judge whether the lowest temperature of the battery system at the start of charging is lower than the preset first temperature threshold Z1, if yes, execute the second step, otherwise end.

[0020] Step 2: According to the ambient temperature at the start of charging, the minimum temperature of the battery system at the start of charging, and the SOC at the start of charging, query the temperature-SOC-coolant inlet temperature flow table to obtain the corresponding coolant inlet temperature X1 and coolant inlet flow Y1, and then perform the third step. Among them, the temperature-SOC-coolant inlet temperature flow meter is the ambient temperature at the beginning of charging, the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com