Double-face sealing rear oil seal tool

A technology of tooling and oil seal, which is applied in the field of oil seal tooling after double-sided sealing, and can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

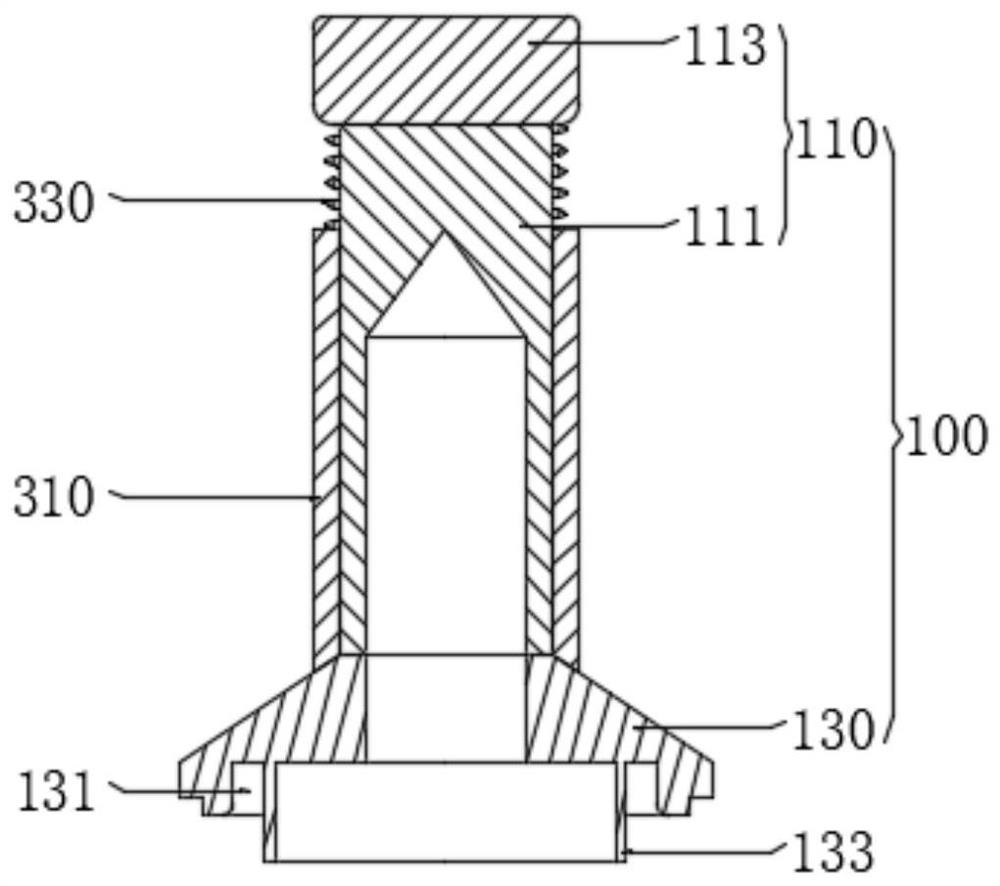

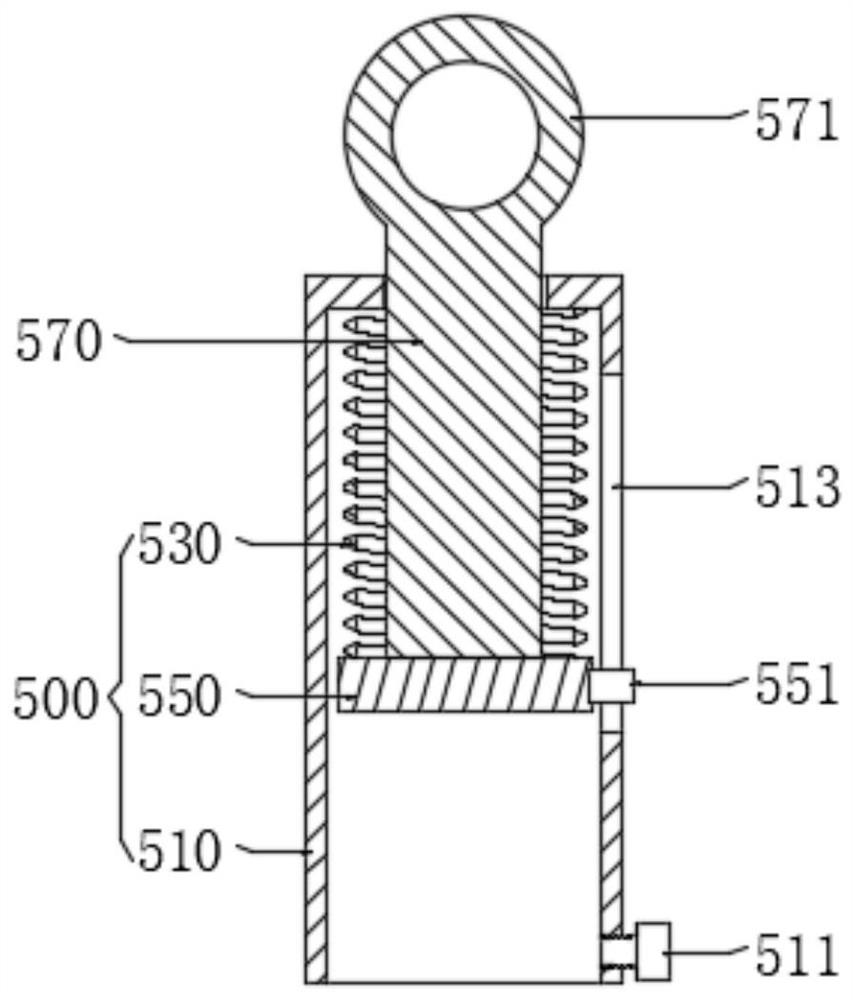

[0034] see Figure 1-5 , the present invention provides a technical solution: a double-sided sealed rear oil seal tooling, including a tooling assembly 100 and a buffer assembly 300 .

[0035] see Figure 1-2 , the tooling assembly 100 includes an impact piece 110 and a press-fit piece 130, the impact piece 110 is fixed on one side of the press-fit piece 130, the other side of the press-fit piece 130 is provided with a circular groove 131, and the edge of the circular groove 131 is opened There are transitional rounded corners, and the bottom of the circular groove 131 is concentrically fixed with a limit ring 133;

[0036] In this embodiment, the impact member 110 includes a straight rod 111 and an impact block 113 , the impact block 113 is fixed at one end of the straight rod 111 , and the other end of the straight rod 111 is fixedly connected with the pressing member 130 .

[0037] It should be noted that the outer diameter of the limiting ring 133 is smaller than the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com