Hydrogen impurity removal device based on hydrogen refueling station

A technology for hydrogen refueling station and gas supply device, which is applied in hydrogen separation, gas treatment, hydrogen separation by selective and reversible absorption, etc., can solve the problems of reducing battery life, poisoning of catalysts and membrane electrodes, irreversibility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

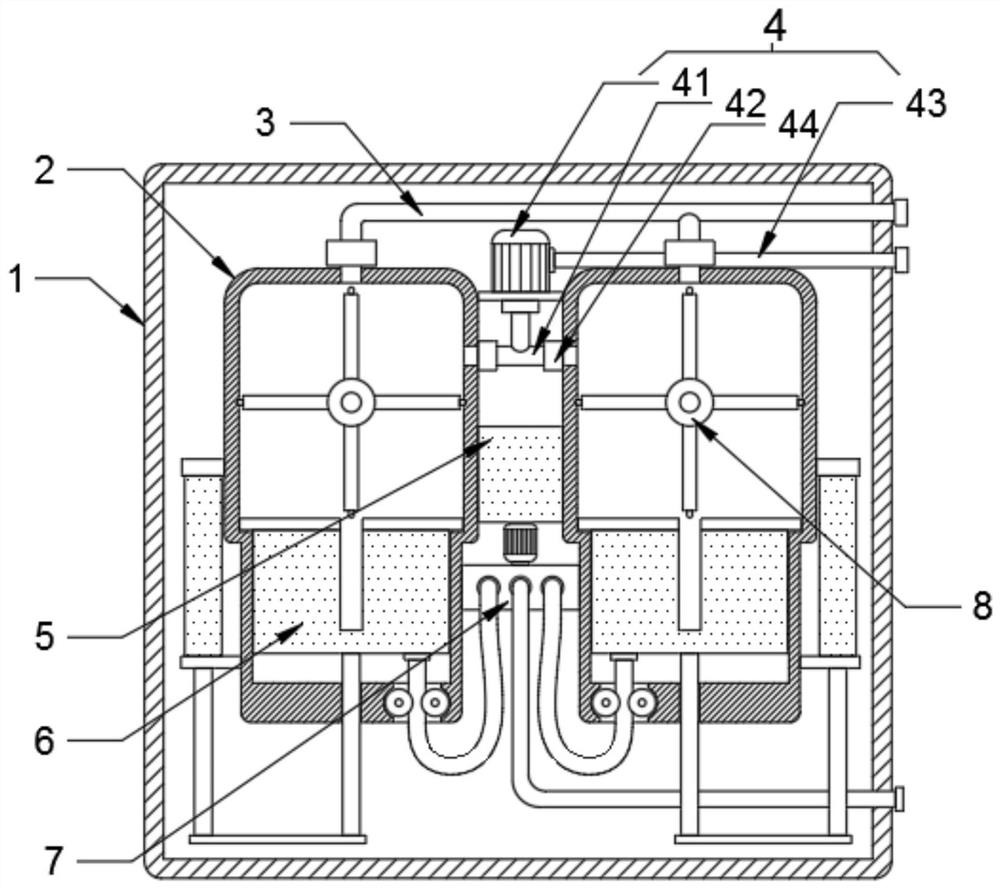

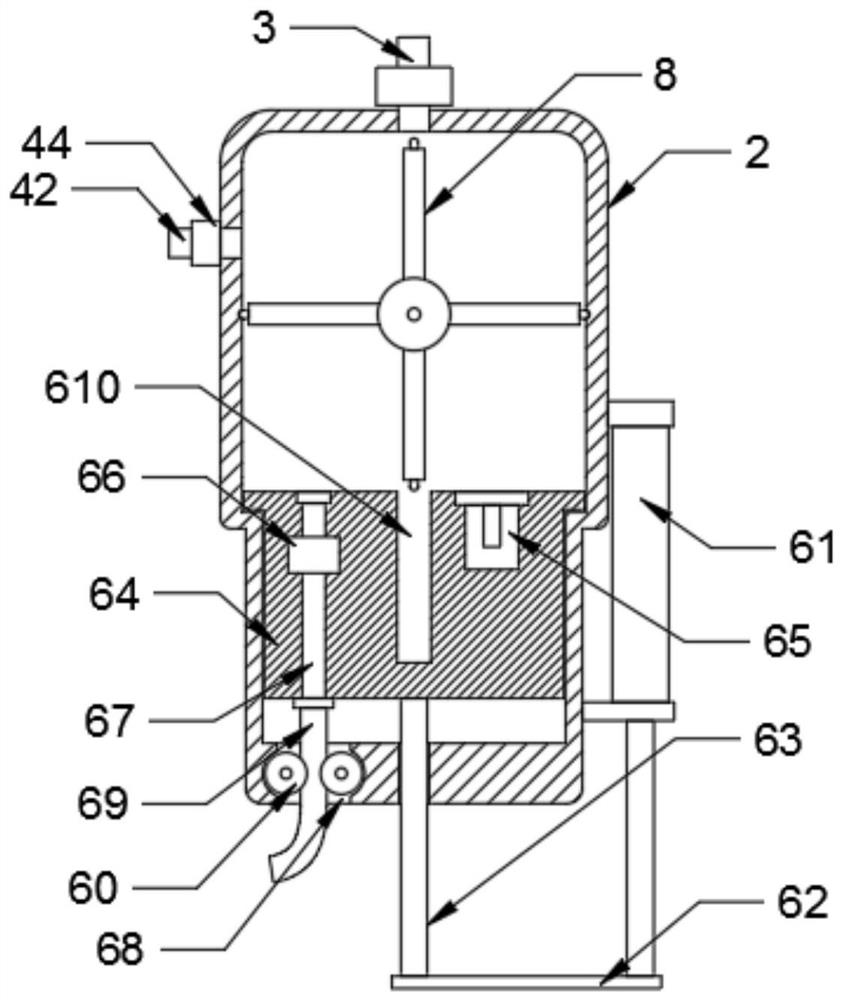

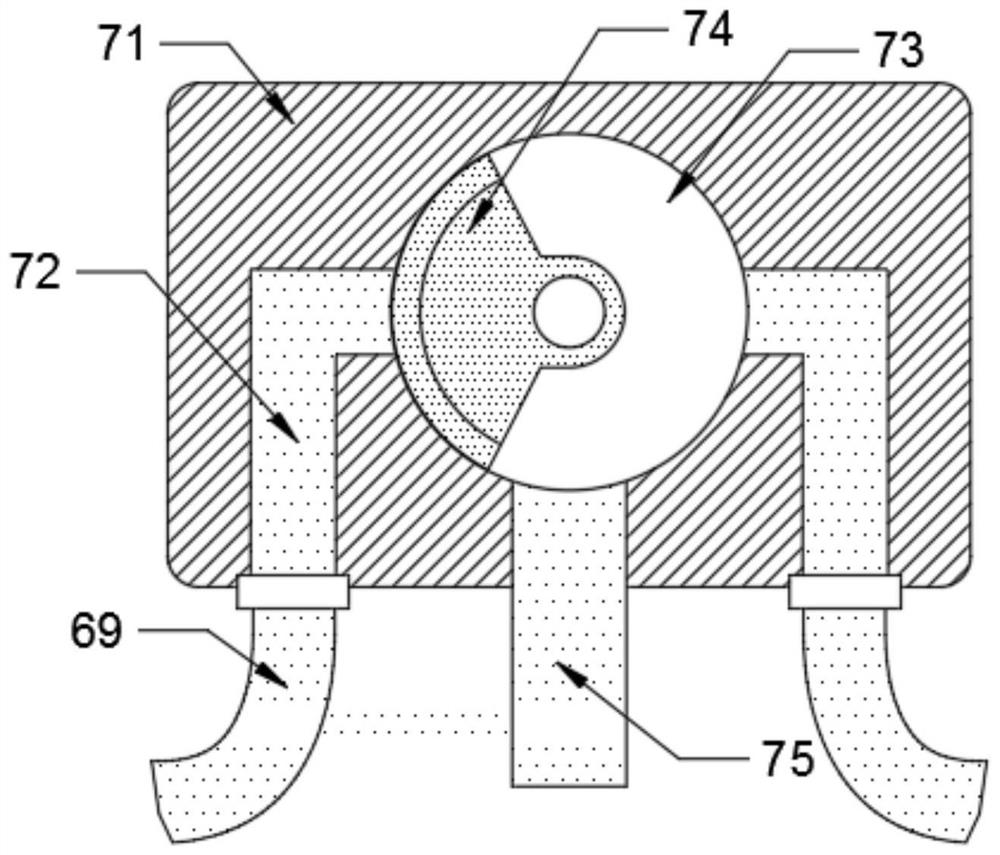

[0026] Please refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 ,in, figure 1 A schematic diagram of the overall structure provided for the present invention; figure 2 Schematic diagram of the structure of the auxiliary row device provided by the present invention; image 3 One of the structural schematic diagrams of the gas supply device provided by the present invention; Figure 4 The second schematic diagram of the structure of the gas supply device provided by the present invention; Figure 5 One of the structural schematic diagrams of the purification device provided by the present invention; Figure 6 The second schematic diagram of the purification device structure provided by the present invention. Including: outer box 1, filter tank 2, exhaust pipe 3 and controller 5.

[0027] In the specific implementat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com