Bag type dust removal device and use method thereof

A bag-type dust removal and driving device technology, applied in the field of bag-type dust removal devices, can solve the problem that the removal efficiency of small particle size dust needs to be improved, and achieve the effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

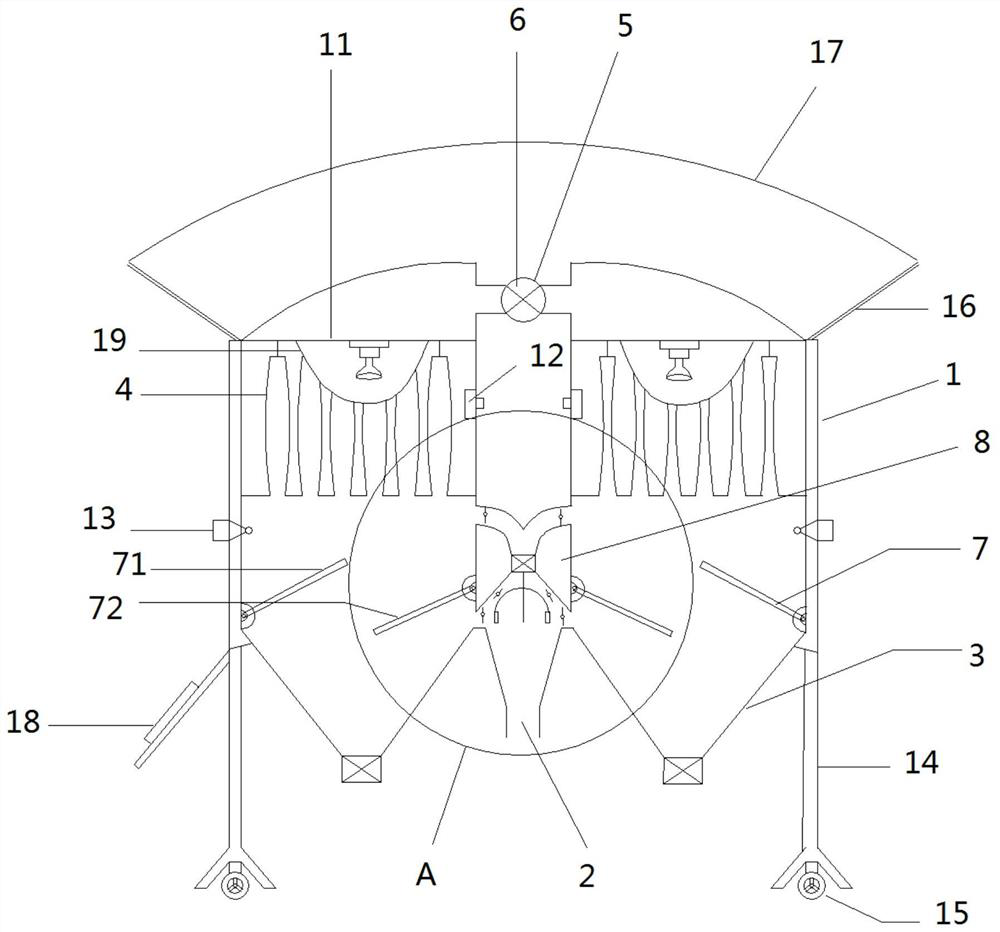

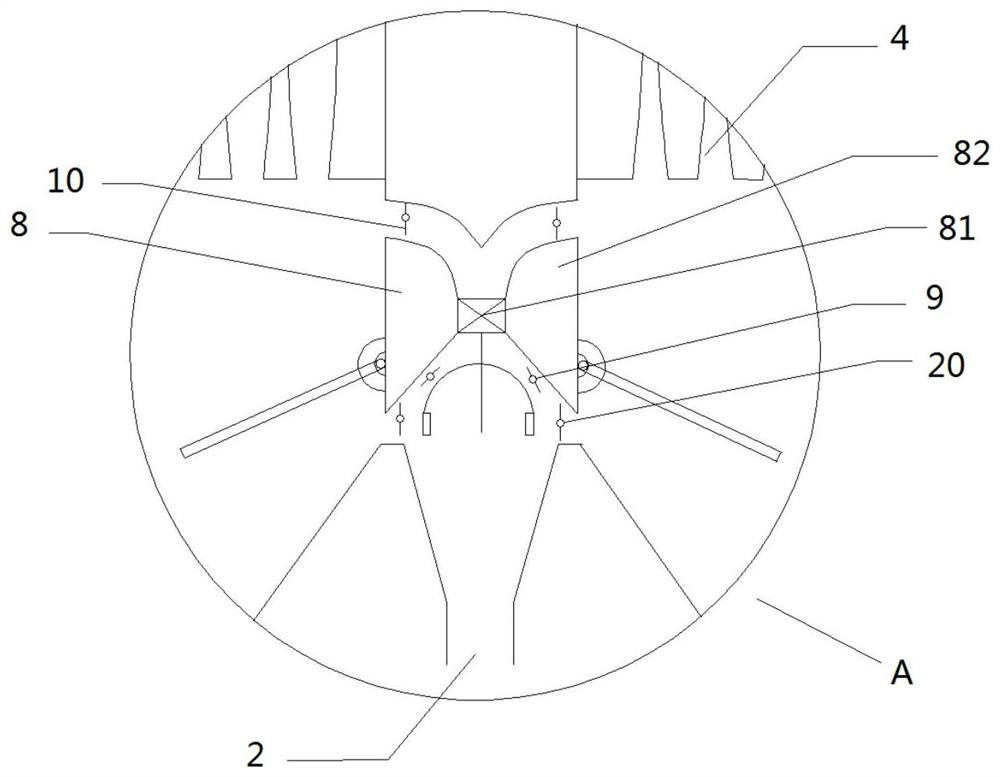

[0029] like figure 1 , figure 2The shown bag-type dust removal device includes a box body 1 with a closed chamber. The bag-type dust removal device in this embodiment is two symmetrically distributed boxes 1, and the shown box body 1 is provided with an air inlet 2. , the airtight chamber is provided with an ash hopper 3, a filter bag 4 and an exhaust manifold 5 from bottom to top, and a negative pressure fan 6 is arranged on the exhaust manifold 5; between the ash hopper 3 and the filter bag 4 There is also a first rotating baffle device 71 and a second rotating baffle device 72 arranged oppositely. The rotating baffle device 7 includes a driving device and a baffle. The driving device is installed on the inner wall of the box body 1. One end of the plate is connected to the drive device and the drive device drives the shutter to rotate around the connection point. The dust-laden gas enters the airtight chamber through the air inlet 2. First, the large particles of dust fa...

Embodiment 2

[0036] A method of using a bag-type dust removal device, comprising the following steps:

[0037] S1: After closing all valves, turn on the negative pressure fan 6 for a period of time, so that the box 1 is in a negative pressure state;

[0038] S2: Open the air inlet valve 20, so that the dust-laden gas enters the gas processing chamber; start the driving device to drive the rotating baffle device 7 to rotate; remove the dust in the dust-laden gas;

[0039] S3: Set the pressure difference value when too much dust affects the flow of gas through the filter bag 4 as the first preset pressure difference value, and the pressure difference value at which dust removal work can be started is the second preset pressure difference value; turn on the fan automatically Control switch, when the pressure sensor 12 detects that the pressure difference between the clean air chamber and the outside of the box 1 increases to the first preset pressure difference value, close the air inlet valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com