Equipment for processing filaments

A filament and equipment technology, which is applied in the field of equipment for processing filaments, can solve problems such as loads, and achieve the effects of low filament steering and low friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

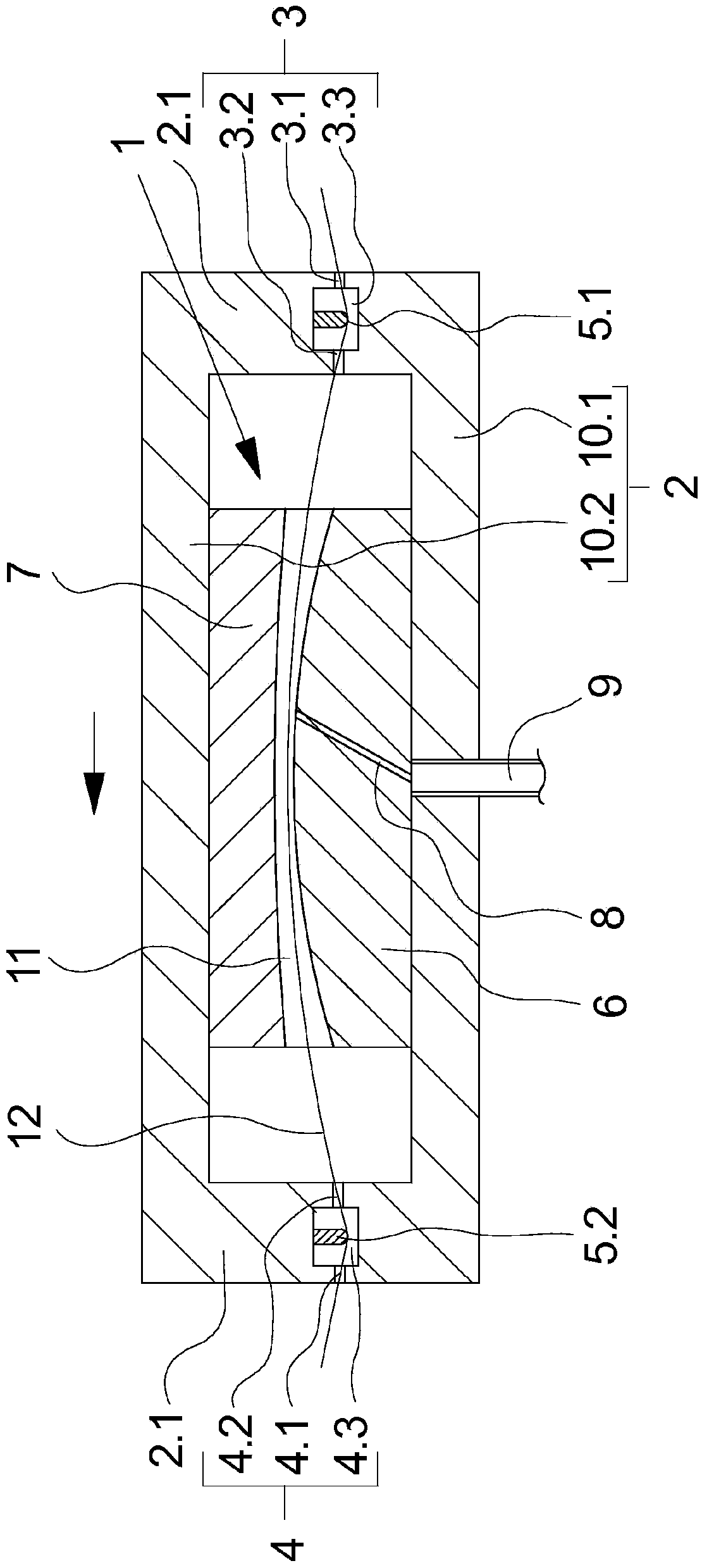

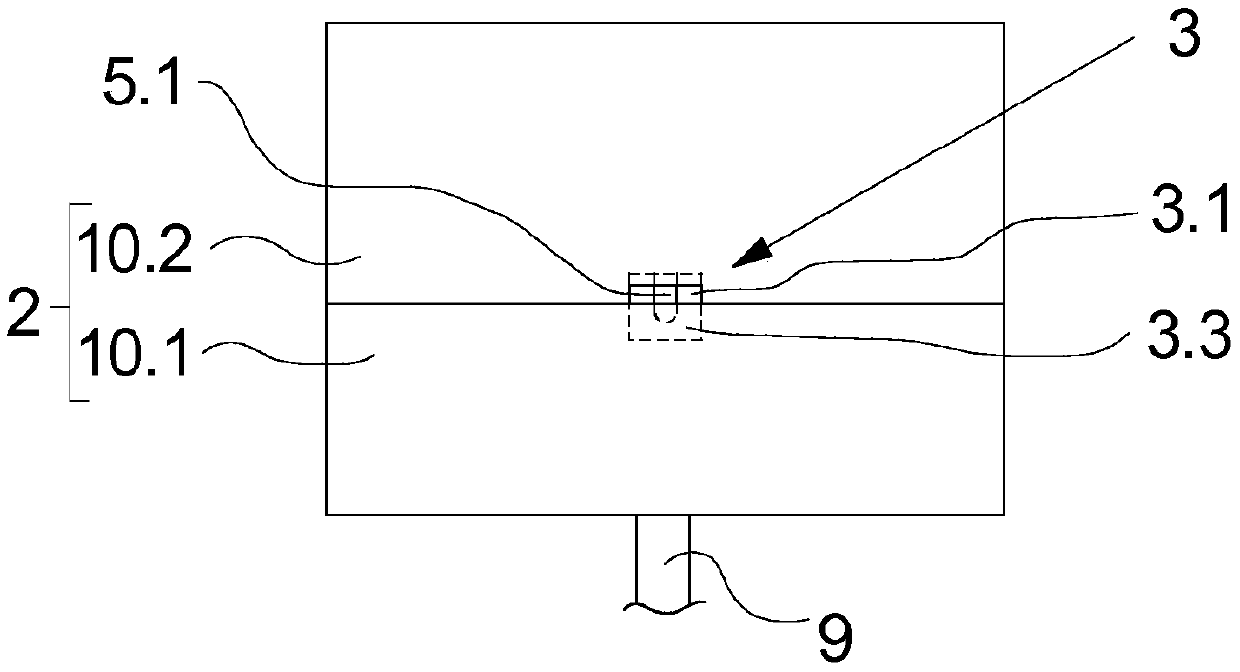

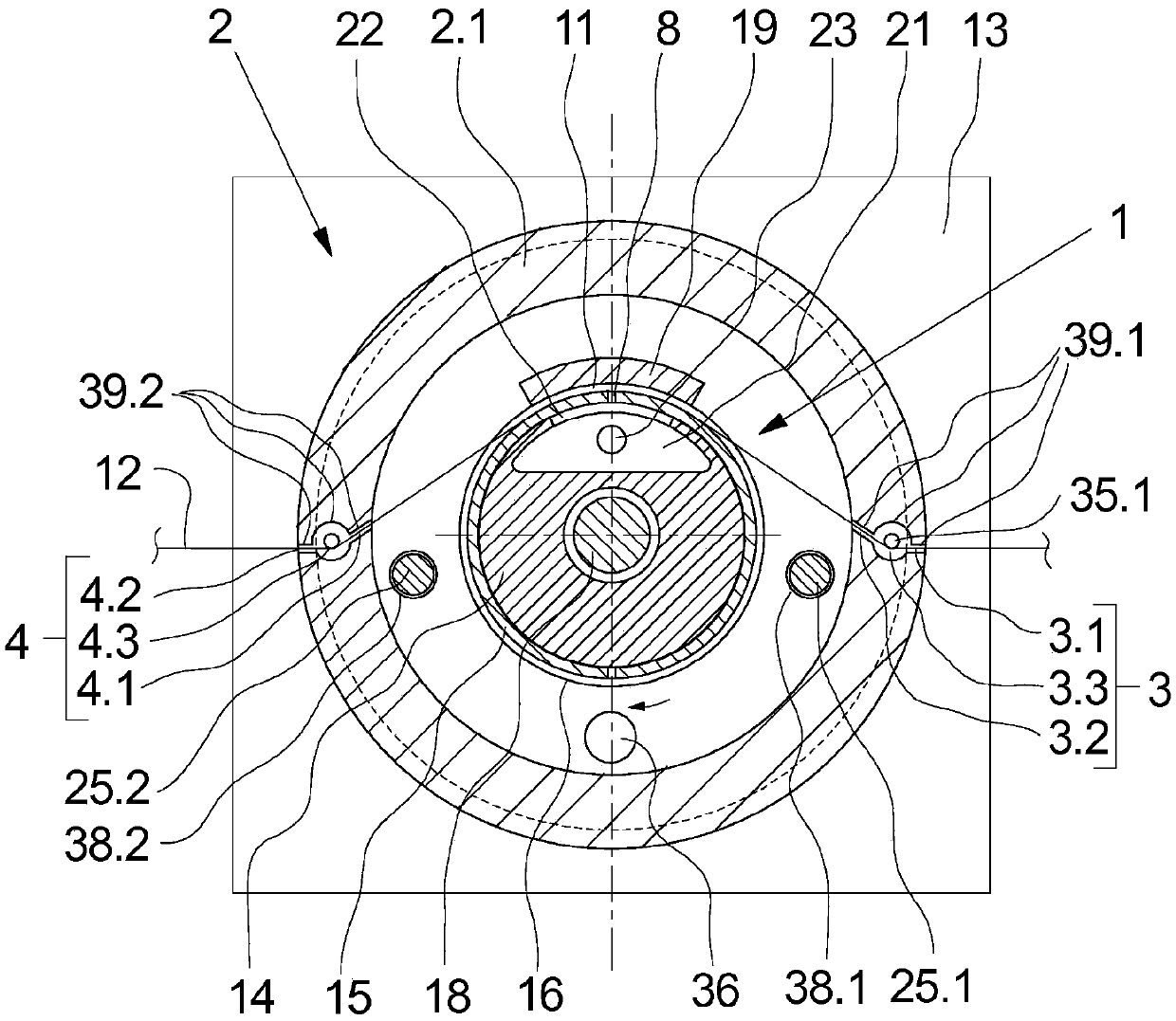

[0031] exist figure 1 and 2 It shows a first exemplary embodiment of a device according to the invention for treating filaments with compressed air. exist figure 1 A cross-sectional view of this embodiment is shown in the figure 2 Its side view is shown in . The following description applies to both figures as long as no reference is made to a certain figure.

[0032] This embodiment comprises a housing 2 which has an eddy current deformation device 1 inside. The housing 2 consists of two housing halves 10 . 1 and 10 . 2 held in a seal-tight manner, which form a filament inlet 3 and a filament outlet 4 opposite each other in their separation gaps.

[0033] Arranged inside the housing 2 is a swirl texturing device 1 , which in this embodiment is formed by a nozzle plate 6 and a baffle 7 , between which a process channel 11 is formed. The treatment channel 11 is open at the ends of the baffle plate 7 and the nozzle plate 6 and lies in a thread travel plane with the filame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com