Ball food forming and processing equipment

A technology for food forming and processing equipment, applied in meat processing equipment, meat processing, metal processing and other directions, can solve the problems of no integrated device for grinding meat and squeezing meatballs and low efficiency of squeezing meatballs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

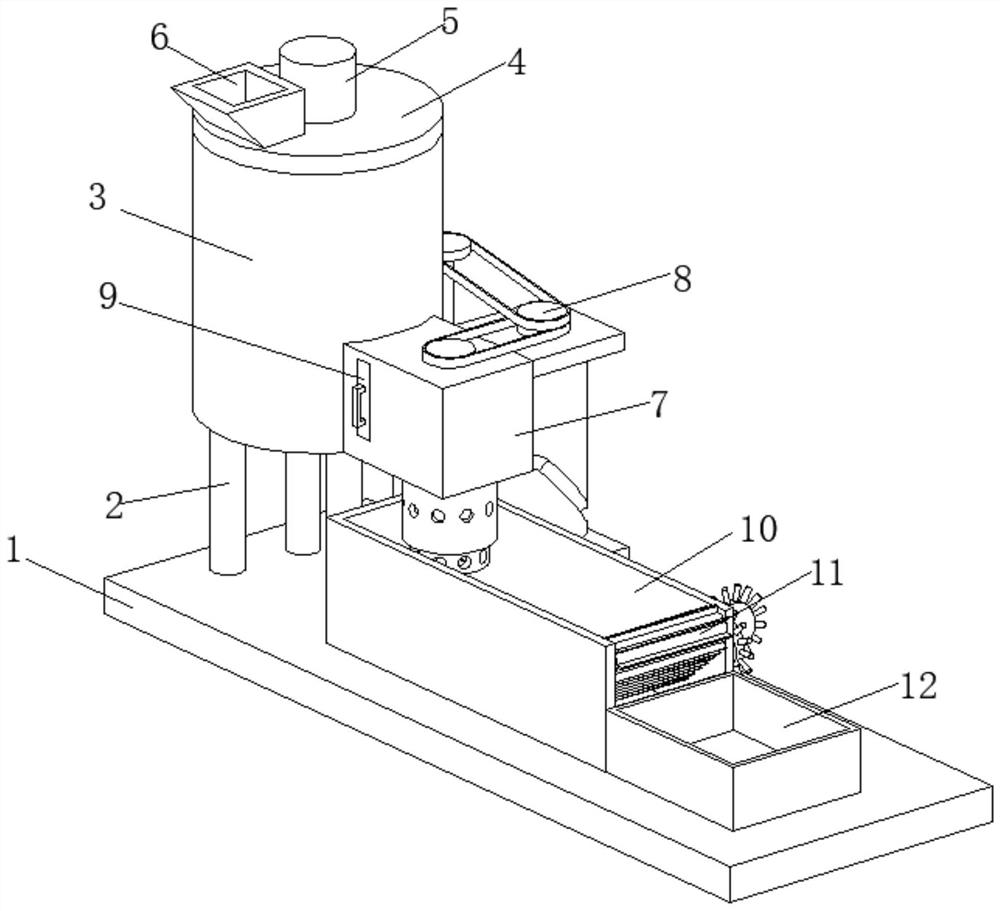

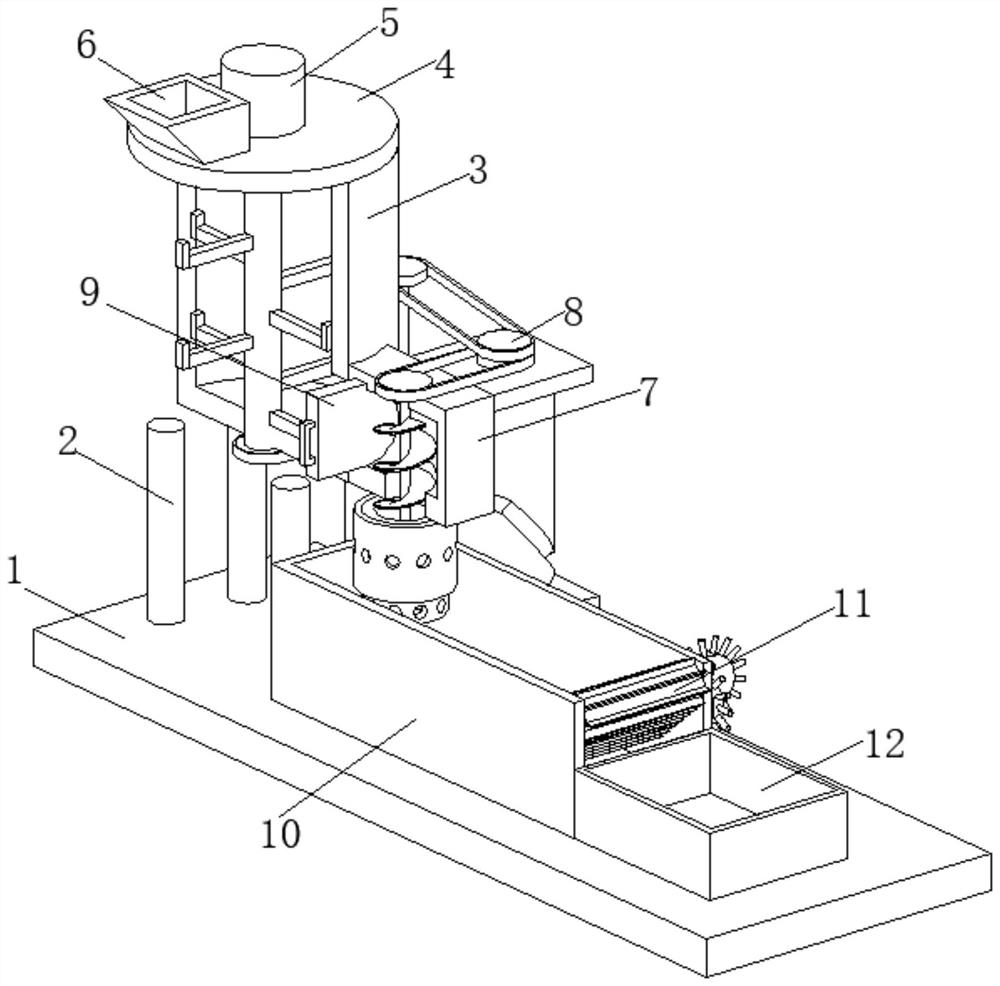

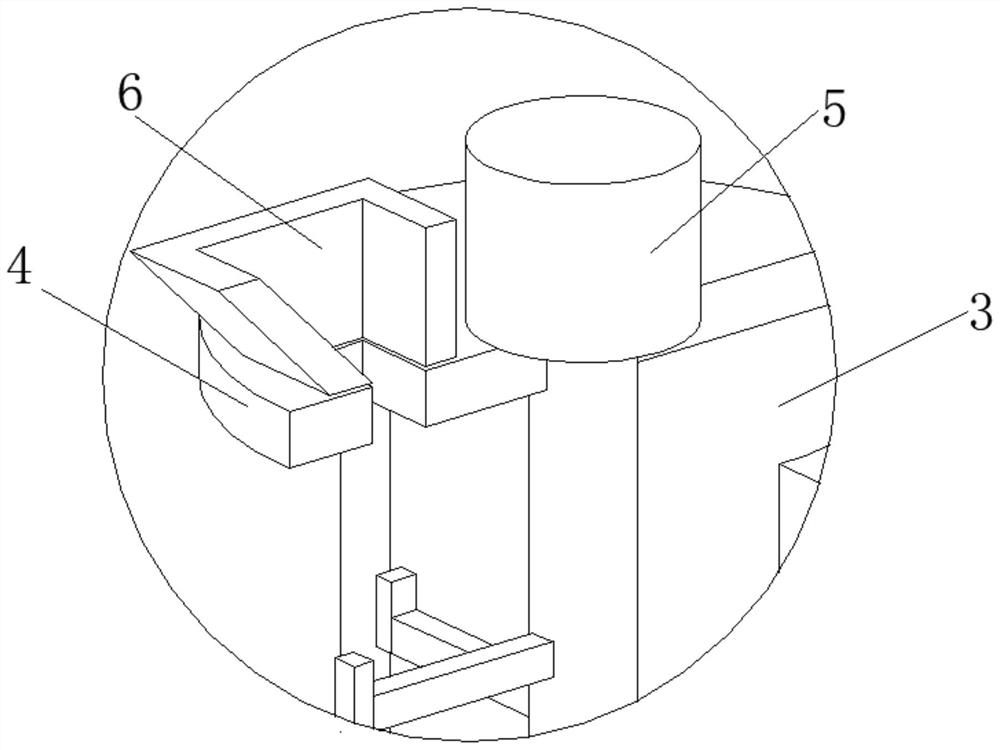

[0030] A kind of pellet food forming processing equipment, such as Figure 1-Figure 6 As shown, including the base 1, the top of the base 1 is welded with four supporting columns 2, the top of the supporting columns 2 is welded with a tank body 3, the top of the tank body 3 is connected with a top cover 4 by bolts, and the top of the top cover 4 is provided with The crushing mechanism 5, the top of the top cover 4 is connected with the feeding frame 6, and the feeding frame 6 is located at the front of the crushing mechanism 5, the surface of the tank body 3 is connected with the connecting block 7, and the top of the connecting block 7 is provided with a transmission mechanism 8 , the inner wall of the connection block 7 is slidingly connected with a pull plate 9, and the top of the base 1 is respectively connected with a box body 10 and a collection box 12 by bolts, and the box body 10 is located between the support column 2 and the collection box 12.

[0031] In this embodi...

Embodiment 2

[0040] Such as Figure 6-Figure 7 As shown, on the basis of Embodiment 1, in this embodiment, the axis of the No. 1 bevel gear 111 is welded and fixed to the surface of the connecting shaft 57, the bottom of the fixed block 114 is welded and fixed to the top of the base 1, and the No. 2 turntable The axis of 117 is welded and fixed to the axis of the No. 1 roller 118 through the connecting rod, and the right side of the fixed block 114 is provided with an adjustment device 115 .

[0041] The shaped meatballs can be automatically salvaged and collected by the collection mechanism 11, so that workers do not need to manually fish them, which can further reduce the labor intensity of the workers, realize the automation of the device, and reduce the input of labor costs.

[0042] The adjusting device 115 includes an electric push rod 1151 , the output end of the electric push rod 1151 is welded with a fixed rod 1152 , and the top end of the fixed rod 1152 is welded with a shaft sle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com