Printed circuit board support assembly

A technology for wiring circuit substrates and components, which is applied in the field of supporting components for wiring circuit substrates, can solve the problems of complicated cutting of connecting parts, etc., and achieve the effect of suppressing peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

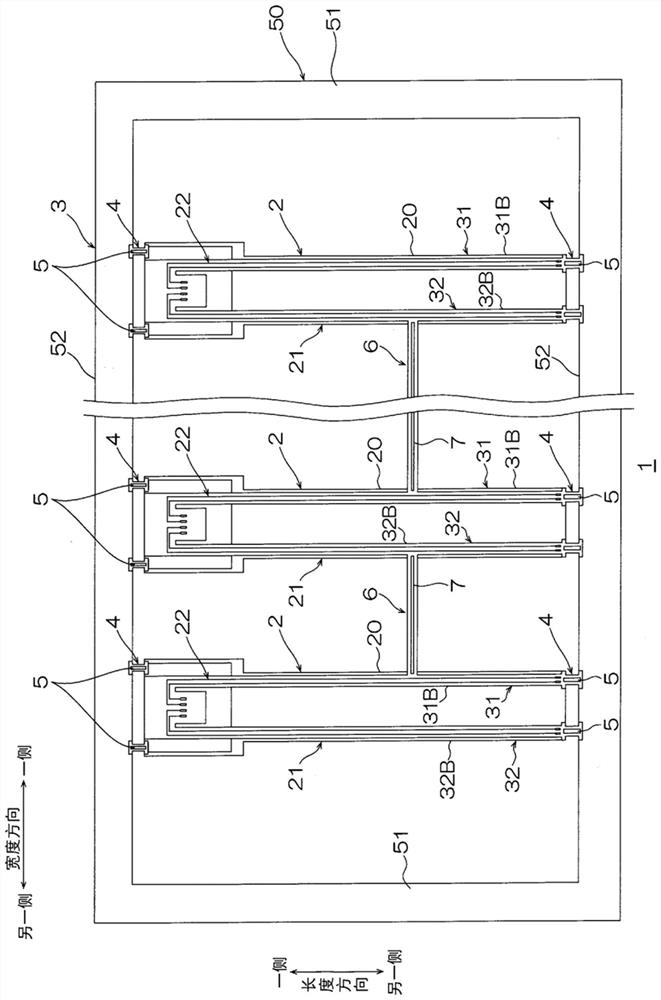

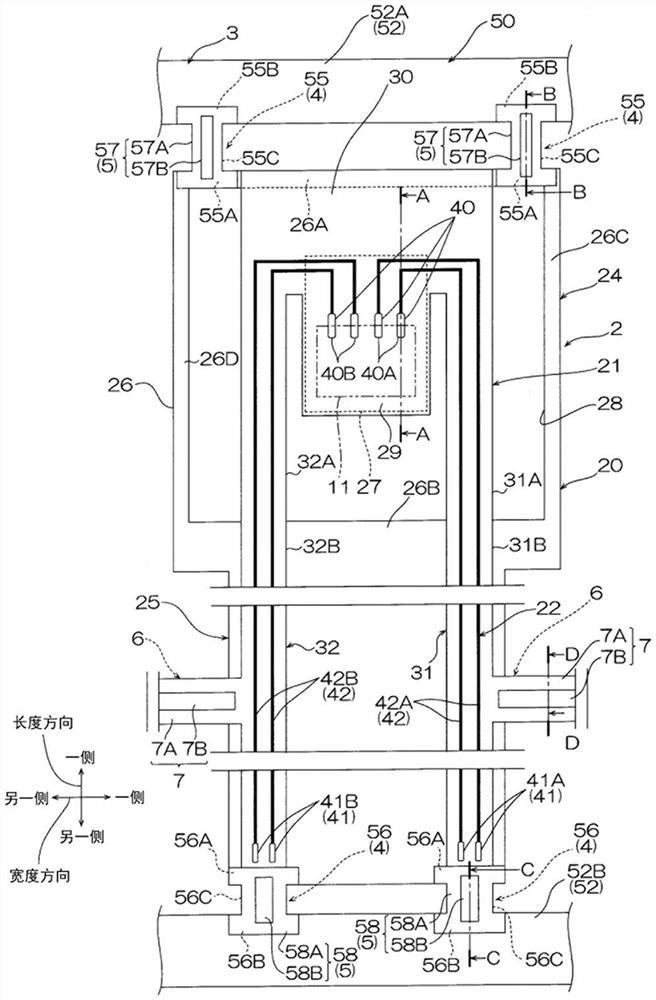

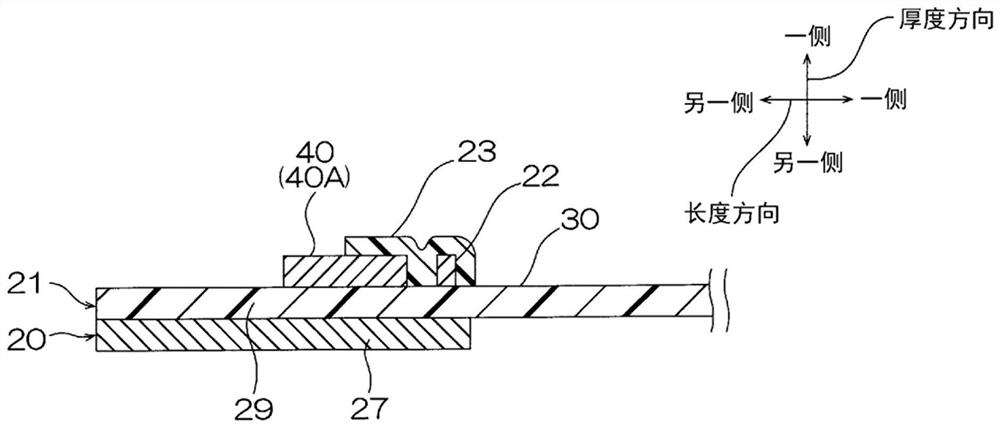

[0038] refer to Figure 1 to Figure 6 The assembly sheet 1 as one embodiment of the wired circuit board supporting assembly of the present invention will be described.

[0039] Such as figure 1 As shown, the assembly sheet 1 includes a plurality of suspension boards with circuit 2 as an example of a wired circuit board, a frame body 3, a plurality of connecting parts 4, a plurality of first reinforcing parts 5, and a plurality of second connecting parts 6. And a plurality of 2nd reinforcing parts 7. In addition, in figure 1 In this example, for convenience, the number of suspension boards with circuits 2 is three, but the number of suspension boards with circuits 2 is not particularly limited.

[0040] 1. Suspension board with circuit

[0041] The suspension board with circuit 2 has a substantially flat belt shape extending in a predetermined direction.

[0042] exist figure 1 In the figure, the thickness direction of the paper is the thickness direction of the suspen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com