Life prediction method for fatigue crack growth of high-lock bolted joints based on stress monitoring

A fatigue crack growth and stress monitoring technology, which is applied in the mechanical field, can solve the problems of limitations and inability to predict the fatigue life of parts, and achieve the effects of convenient operation, simple structure and low labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Structure and working process of the present invention are described further below:

[0034] The invention proposes a stress monitoring-based single-detail high-lock bolt connection test piece fatigue test and crack propagation life prediction method. The research work of the present invention provides a new method and idea for independently designing fatigue tests and predicting fatigue crack growth life in my country.

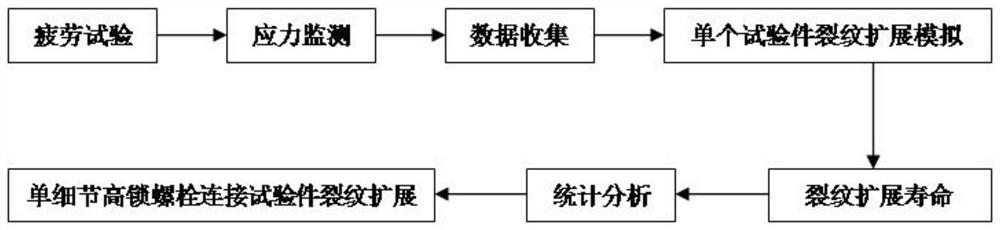

[0035] Such as figure 1 As shown, the fatigue testing machine is set up through the fatigue test control system to apply a constant amplitude load to the high-lock bolt standard test piece, and the foil strain gauge is attached to the hole of the single-detail standard test piece, and the stress monitoring system is used to monitor the stress change of the hole edge of the test piece in real time , the test signal is connected to the NI data collector and sent to the computer for real-time processing, displaying the stress change process with time in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com