Silica sol composite thermal insulation real stone paint

A composite thermal insulation, silica sol technology, applied in the direction of coating, can solve the problems of insufficient heat resistance, poor anti-contamination ability, etc., achieve the effect of improving heat resistance and anti-fouling ability, and significantly promote the application significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

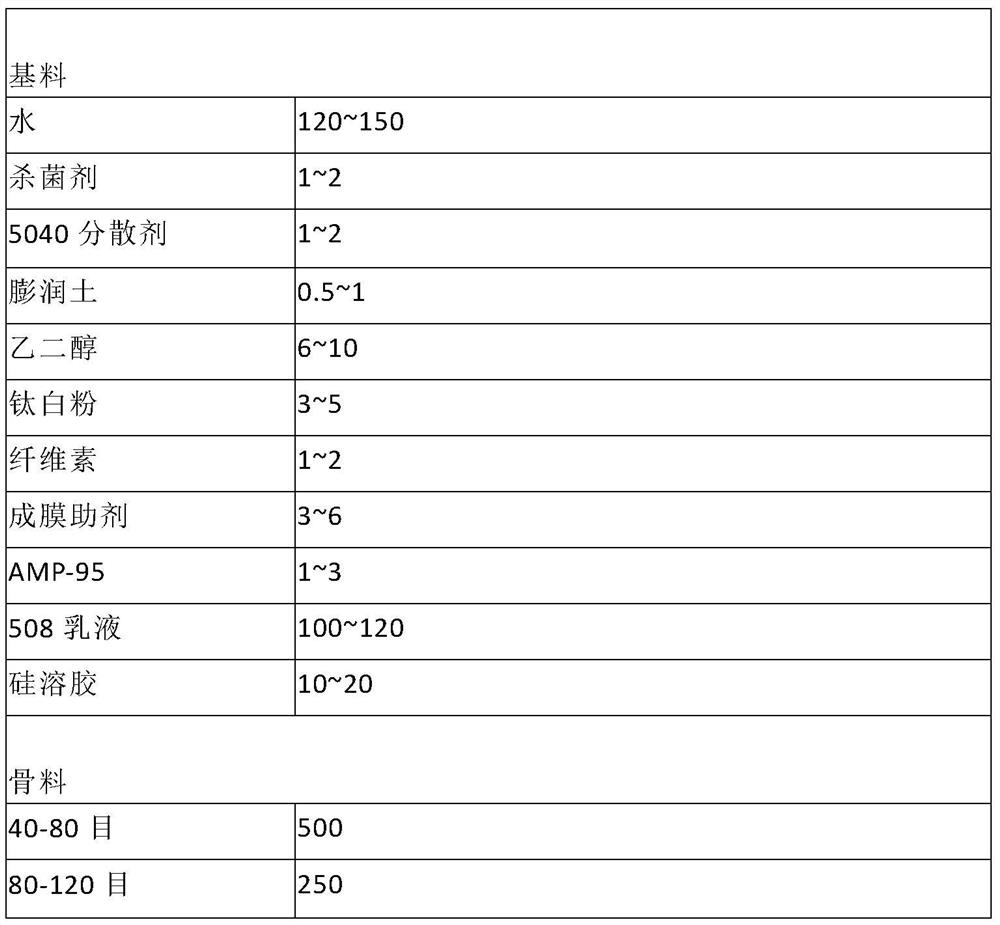

[0019] A silica sol composite thermal insulation real stone paint, the composition of which is as follows in parts by mass: 120 parts of water, 1 part of bactericide, 1 part of 5040 dispersant, 0.5 parts of bentonite, 6 parts of ethylene glycol, 3 parts of titanium dioxide, and 1 part of cellulose , 3 parts of film-forming aid, 1 part of AMPO-95, 100 parts of emulsion, 20 parts of silica sol, 500g of 40-80 mesh white sand, 250g of 80-120 mesh white sand.

[0020] Wherein, after adding the dispersant, stir at low speed for 10 minutes.

[0021] Wherein, after adding titanium dioxide, stir at high speed for 25 minutes.

[0022] Wherein, after adding the silica sol, stir at a low speed for 20 minutes.

[0023] Wherein, cellulose is hydroxyethyl cellulose ether.

[0024] Wherein, the titanium dioxide is rutile type titanium dioxide.

[0025] Wherein, the fungicide is an isothiazolinone fungicide.

[0026] Wherein, the silica sol particle diameter is 20nm, pH=9.5.

Embodiment 2

[0028] A silica sol composite real stone paint, the composition of which is as follows in parts by mass: 120 parts of water, 1 part of bactericide, 1 part of 5040 dispersant, 0.5 parts of bentonite, 6 parts of ethylene glycol, 3 parts of titanium dioxide, 1 part of cellulose, 3 parts of film-forming aid, 1 part of AMPO-95, 90 parts of emulsion, 30 parts of silica sol, 500g of 40-80 mesh white sand, 250g of 80-120 mesh white sand.

[0029] Wherein, after adding the dispersant, stir at low speed for 10 minutes.

[0030] Wherein, after adding titanium dioxide, stir at high speed for 25 minutes.

[0031] Wherein, after adding the silica sol, stir at a low speed for 20 minutes.

[0032] Wherein, cellulose is hydroxyethyl cellulose ether.

[0033] Wherein, the titanium dioxide is rutile type titanium dioxide.

[0034] Wherein, the fungicide is an isothiazolinone fungicide.

[0035] Wherein, the silica sol particle diameter is 20nm, pH=9.5.

Embodiment 3

[0037] A silica sol composite real stone paint, the composition of which is as follows in parts by mass: 120 parts of water, 1 part of bactericide, 1 part of 5040 dispersant, 0.5 parts of bentonite, 6 parts of ethylene glycol, 3 parts of titanium dioxide, 1 part of cellulose, 3 parts of film-forming aid, 1 part of AMPO-95, 80 parts of emulsion, 40 parts of silica sol, 500g of 40-80 mesh white sand, 250g of 80-120 mesh white sand.

[0038] Wherein, after adding the dispersant, stir at low speed for 10 minutes.

[0039] Wherein, after adding titanium dioxide, stir at high speed for 25 minutes.

[0040] Wherein, after adding the silica sol, stir at a low speed for 20 minutes.

[0041] Wherein, cellulose is hydroxyethyl cellulose ether.

[0042] Wherein, the titanium dioxide is rutile type titanium dioxide.

[0043] Wherein, the fungicide is an isothiazolinone fungicide.

[0044] Wherein, the silica sol particle diameter is 20nm, pH=9.5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com