Environment-friendly glass stamp-pad ink capable of becoming dry in one second and preparation method thereof

A technology of instant drying and printing ink, which is applied in the field of environmental protection instant drying glass printing ink and its preparation, which can solve the problems of product quality reduction, construction efficiency reduction, equipment accelerated drying, etc., to improve wettability and drying speed, improve construction efficiency, Harm reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

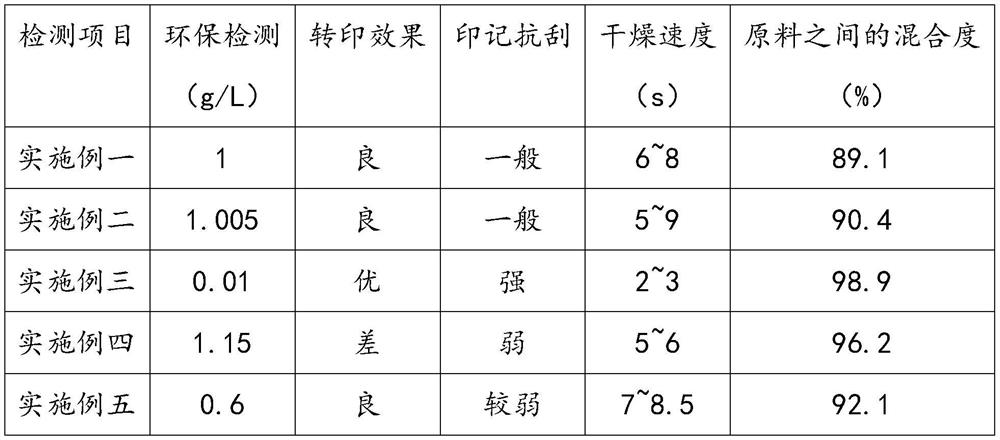

Examples

Embodiment 1

[0024] Step 1: Fully grind each raw material with grinding equipment, and then sieve the particles with a 200-mesh sieve after grinding.

[0025] Step 2: Open the feed port of the reactor, pour 55% ethanol and 16.5% n-butanol into the reactor, then take 2% natural pigment and pour it into the reactor, the stirring temperature of the reactor is 45°C, and the stirring speed is 1200r / min, the stirring time is 10min, to obtain fluid one, then add the water-soluble polymer 4 and phytic acid 0.75 to the fluid one in the reaction kettle in turn, the reaction kettle continues to stir, and the stirring temperature of the reaction kettle is 45°C at this time, stir The speed is 1200r / min, the stirring time is 10min, and fluid 2 is obtained, and then take 0.2% of fluorescent powder, 0.1% of titanate coupling agent, 0.1% of thermal oxygen aging anti-aging agent, and 0.2% of sodium salicylate into the reaction kettle in sequence. In fluid two, the reactor was stirred again. At this time, t...

Embodiment 2

[0029] Step 1: Fully grind each raw material with grinding equipment, and then sieve the particles with a 200-mesh sieve after grinding.

[0030] Step 2: Open the feed port of the reactor, pour 70% of ethanol and 17% of n-butanol into the reactor, and then pour 3% of natural pigment into the reactor, the stirring temperature of the reactor is 100°C, and the stirring speed is 1200r / min, the stirring time is 15min, and fluid 1 is obtained, then 9% of water-soluble polymer and 2% of phytic acid are sequentially added to fluid 1 in the reactor, and the reactor continues to stir, and the stirring temperature of the reactor is 100°C at this time , the stirring speed is 1200r / min, and the stirring time is 15min to obtain fluid 2, then take 1% of fluorescent powder, 0.51% of titanate coupling agent, 1.5% of thermal oxygen aging anti-aging agent, and 1% of sodium salicylate into the reaction kettle in turn In the fluid two in the reactor, the reactor was stirred again. At this time, t...

Embodiment 3

[0034] Step 1: Fully grind each raw material with grinding equipment, and then sieve the particles with a 200-mesh sieve after grinding.

[0035]Step 2: Open the feed port of the reactor, pour 75% of ethanol and 17.45% of n-butanol into the reactor, then take 4% of natural pigment and pour into the reactor, the stirring temperature of the reactor is 45°C, and the stirring speed is 1200r / min, the stirring time is 10min, to obtain fluid one, then add 14% of water-soluble polymer and 2.5% of phytic acid into fluid one in the reactor in turn, the reactor continues to stir, and the stirring temperature of the reactor is 45°C , the stirring speed is 1200r / min, and the stirring time is 10min to obtain fluid 2, then take 1.5% of fluorescent powder, 1% of titanate coupling agent, 2% of thermal oxygen aging anti-aging agent, and 1.5% of sodium salicylate into the reaction kettle in turn In the fluid two in the reactor, the reactor was stirred again. At this time, the stirring temperatu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com