Molten glass stirring control system and method for laboratory

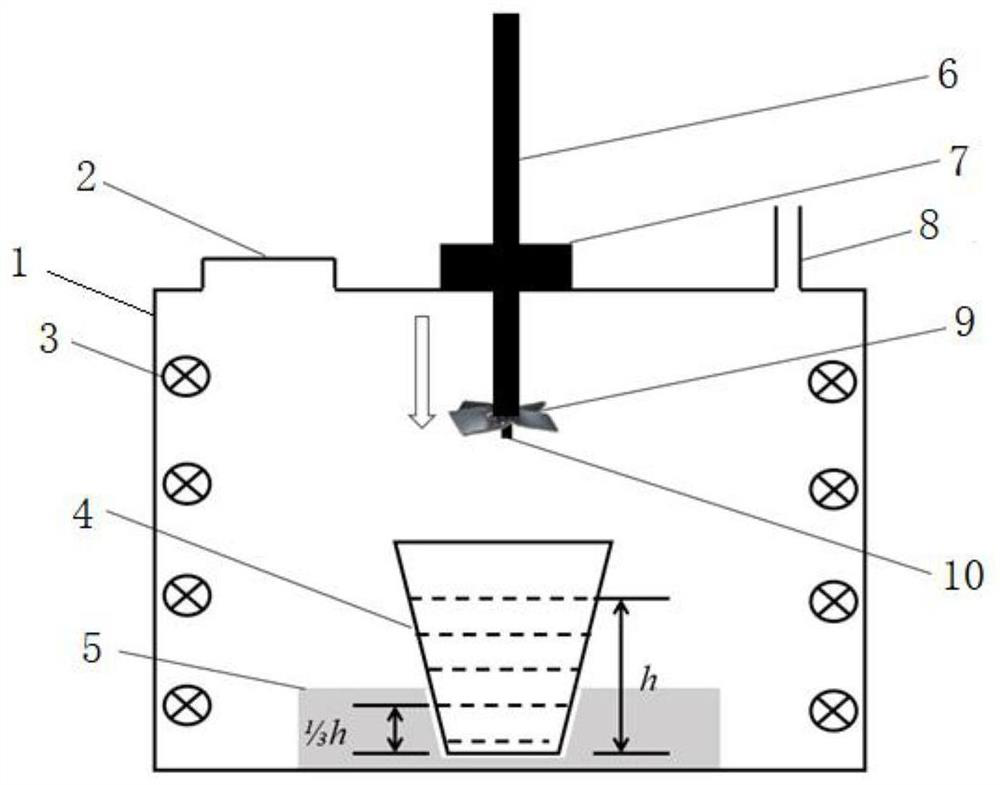

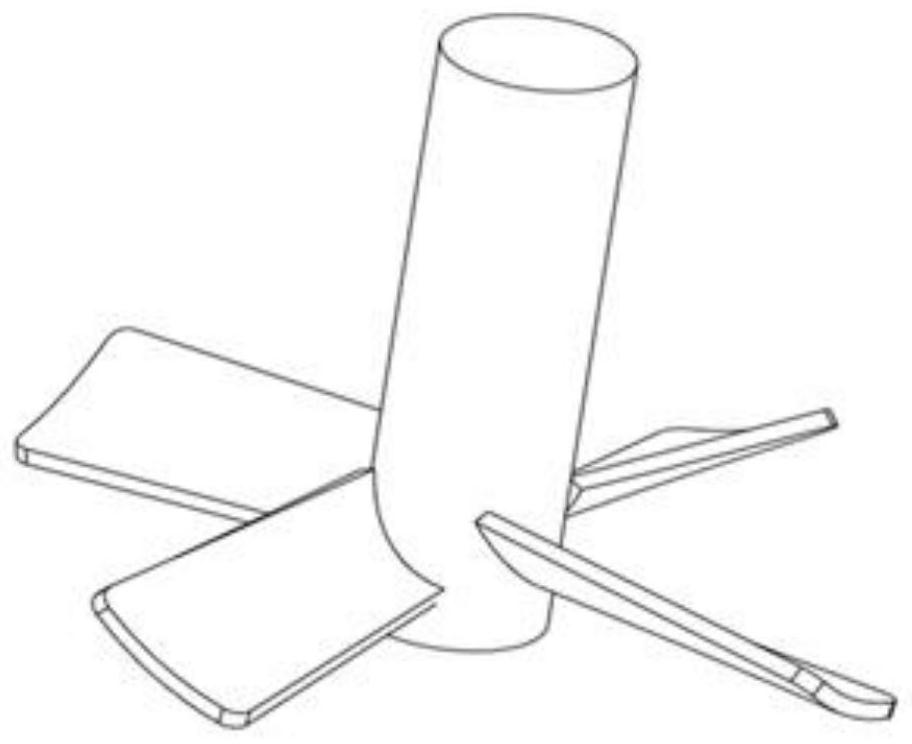

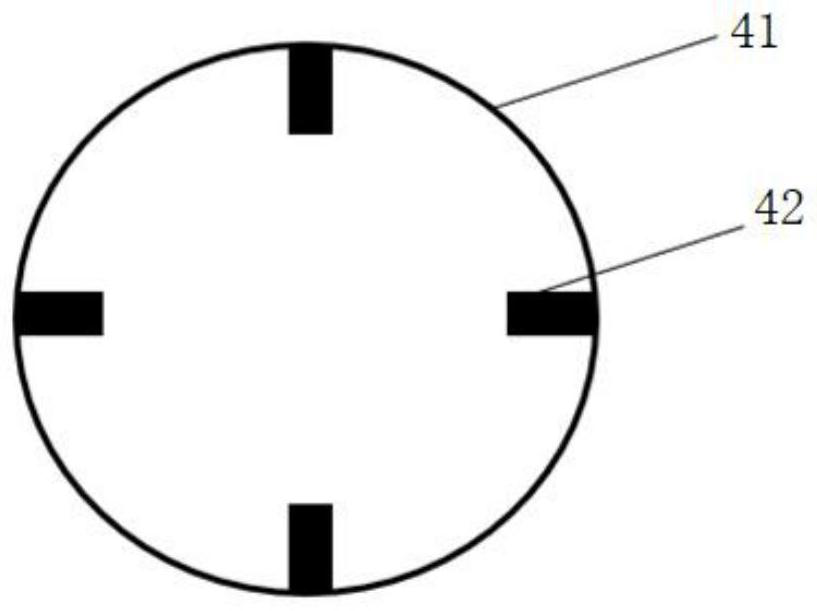

A technology for molten glass and laboratory use. It is applied in glass manufacturing equipment, glass furnace equipment, manufacturing tools, etc. It can solve problems such as uneven stirring, inclusions, and poor sealing of the furnace body, so as to facilitate the distribution of the temperature field and increase the temperature. The degree of mixing and avoiding the effect of poor melting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0061]

[0062]

example 2

[0064]

example 3

[0066]

[0067]

[0068] The molten glass stirring control system and method used in the laboratory of the present invention can realize the measurement and precise control of the temperature of the molten glass during the glass melting process, fully meet the temperature conditions required for melting, and emphatically realize the in-situ control of the molten glass Automatic stirring and homogenization, and the real-time change of the stirring rotation speed through the temperature-linked stirring motor is more conducive to the homogenization effect of the glass liquid. From the comparison between the above three examples and the prior art, it can be seen that the glass prepared by the process of the present invention Visible bubbles and streaks are significantly reduced, and the performance test data at different parts of the same piece of glass fluctuate less and are relatively stable, and glass samples with uniform and stable quality can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com