Full-automatic screen printing equipment

A fully automatic, silk-screen printing technology, applied in screen printing machines, printing, printing machines, etc., can solve the problems of large hydraulic cylinder loss, etc., and achieve the effects of convenient operation, automation, and simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to further explain the technical means and effects that the present invention adopts to achieve the intended invention purpose, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

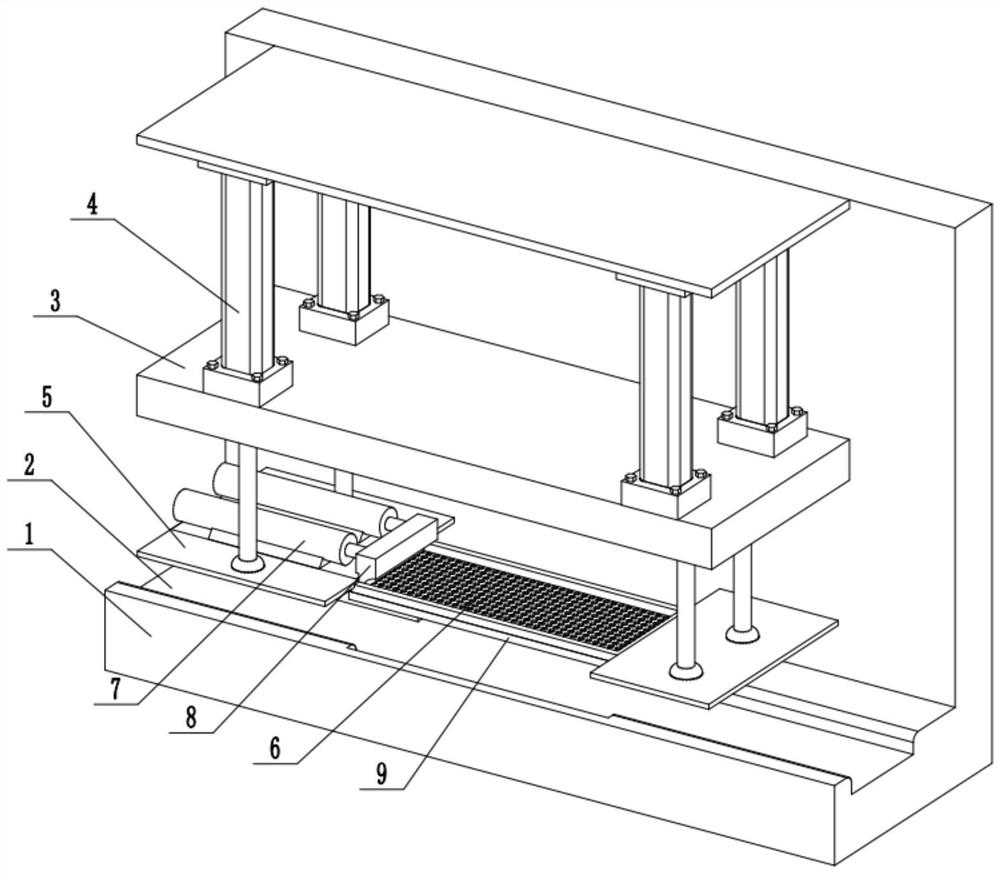

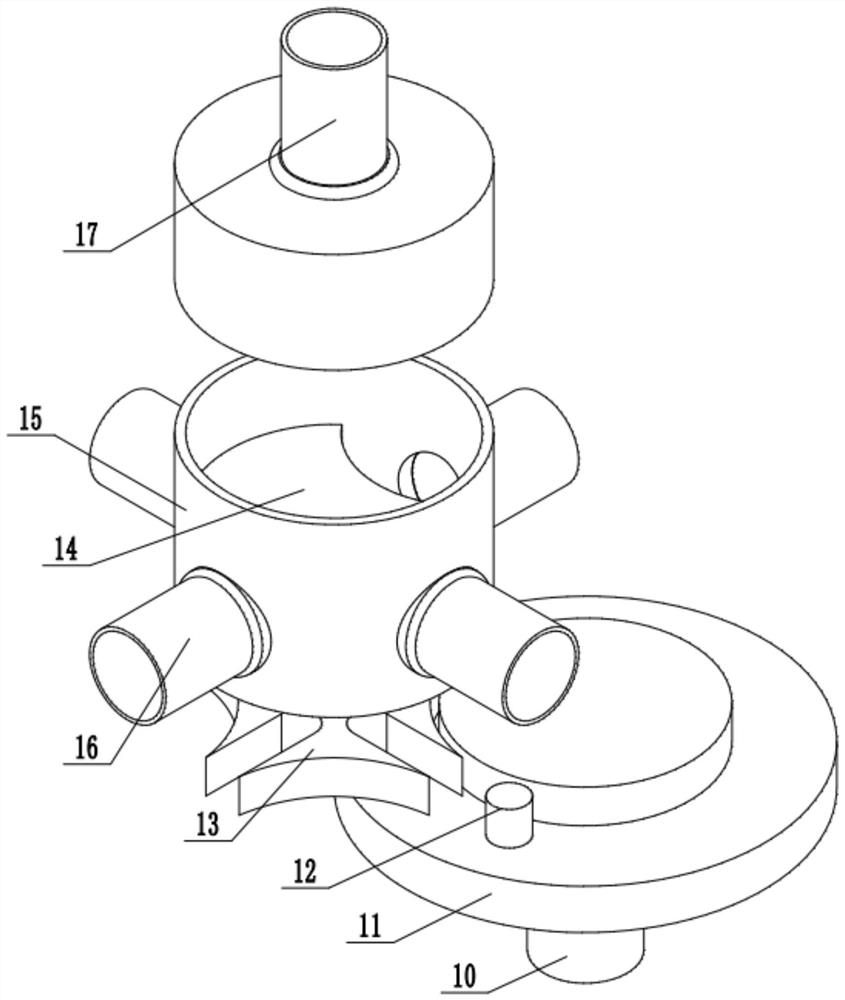

[0028] The reference signs in the drawings of the description include: workbench 1, chute 2, fixed plate 3, first driving mechanism 4, first sealing cylinder 401, first piston plate 402, first piston rod 403, sealing washer 404, Support plate 5, screen printing plate 6, second driving mechanism 7, scraper 8, pressing bar 9, hydraulic motor output shaft 10, first runner 11, slider 12, second runner 13, conversion block 14 , Oil conversion pipe 15, driving oil pipe 16, first oil inlet 1601, second oil inlet 1602, oil outlet pipe 17.

[0029] A kind of automatic screen printing equipment, embodiment such as figure 1 Shown: including workbench 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com