Full-automatic pre-pressing device for flame-retardant shaving board

A fully automatic, particle board technology, applied in home appliances, wood processing appliances, other home appliances, etc., can solve the problems of low hardness and toughness of particle board, and achieve the effect of protecting personal information security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

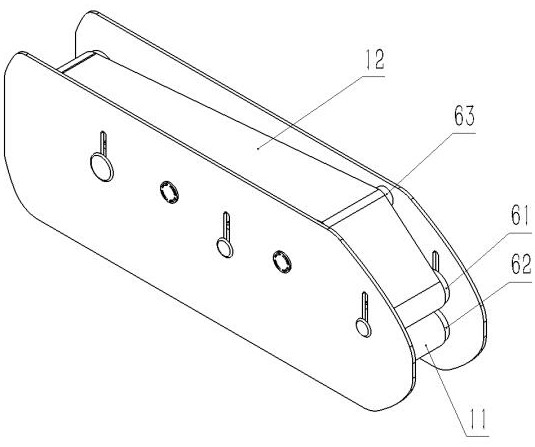

[0025] Examples, see figure 1 , a fully automatic pre-pressing device for flame-retardant particleboard, including: a lower pressure steel belt 11 and an upper pressure steel belt 12. The feature is that: the pre-pressing device is divided into a feed area 2, a light pressure area 3, and a vibration compaction area from front to back. Zone 4, vibration pressurization zone 5, and discharge zone 6.

[0026] 2. A fully automatic pre-pressing device for flame retardant particleboard according to claim 1, characterized in that: an upper driving wheel 21 is arranged in the feeding area 2, and a lower driving wheel 22 is arranged directly below the upper driving wheel.

[0027] Examples, see figure 1 , the light nip zone 3 is provided with a first pressure roller 31, and a first support roller 32 is arranged directly below the first pressure roller 31, and the distance between the first pressure roller 31 and the second support roller 32 is adjustable, and the first pressure roller ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com