Intelligent residue removing device for precision casting product

A technology of precision casting and products, applied in the field of intelligent residue removal devices, can solve the problems of inability to polish products in all directions, and achieve the effect of improving grinding accuracy and grinding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

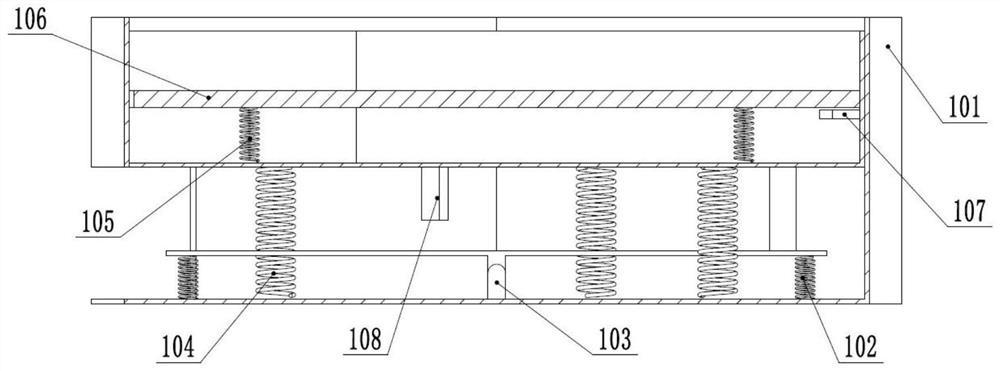

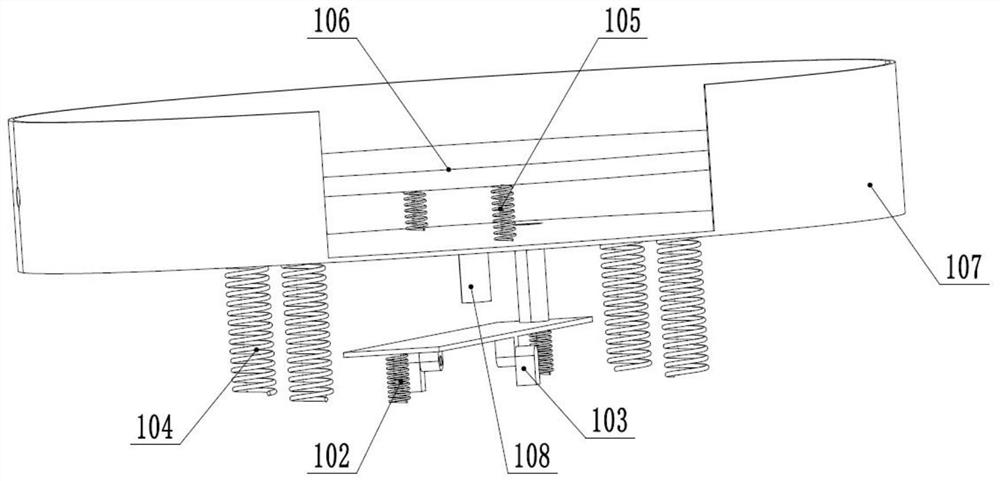

[0025] Example: Reference figure 1 The shown intelligent residue removal device for precision casting products includes a dumping device 1. The dumping device 1 is provided with a twisting device 2 for clamping and grinding the rotating product. The upper end of the twisting device 2 is provided with a surface for grinding the product surface. The grinding device 3 and the hole grinding device 4 for grinding the product holes.

[0026] refer to figure 2 , image 3The shown pouring device 1 includes a casing 101, a bottom spring 102 is fixedly arranged on the casing 101, a rotating plate 103 is fixedly installed on the bottom spring 102, a rotating block is provided at the middle end of the rotating plate 103, and a sliding block is arranged on the casing 101. Weight plate 107, the weight plate 107 is rotated with a material receiving plate 106, and the weight plate 107 is provided with an extrusion spring II 105 to undertake the material receiving plate 106, the lower end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com