Adaptive machining method for leading and trailing edges of aero-engine turbine blades

A technology for aero-engines and turbine blades, which is applied to electric processing equipment, processing electrodes, metal processing equipment, etc., can solve the problems of quality differences in processed blades, small blade curvature radius, and turbulence in the outflow field, so as to eliminate quality differences and ensure The effect of processing quality and flow field stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the technical means, creative features, achievement goals and effects realized by the present invention easy to understand, the present invention will be further described below with reference to the specific embodiments.

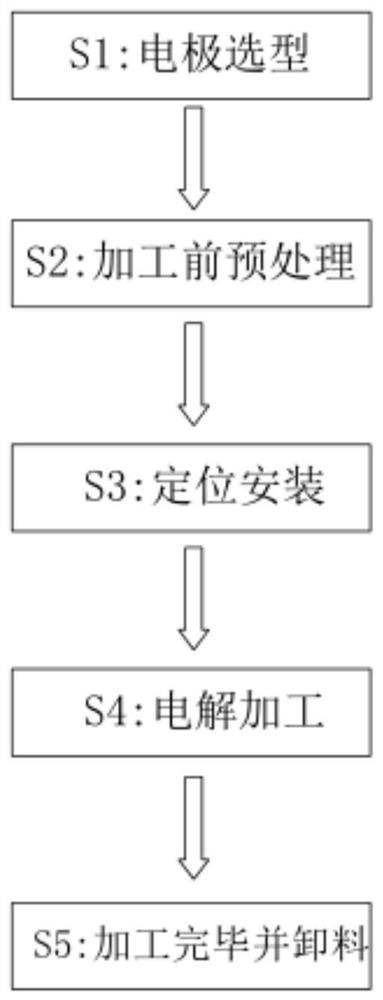

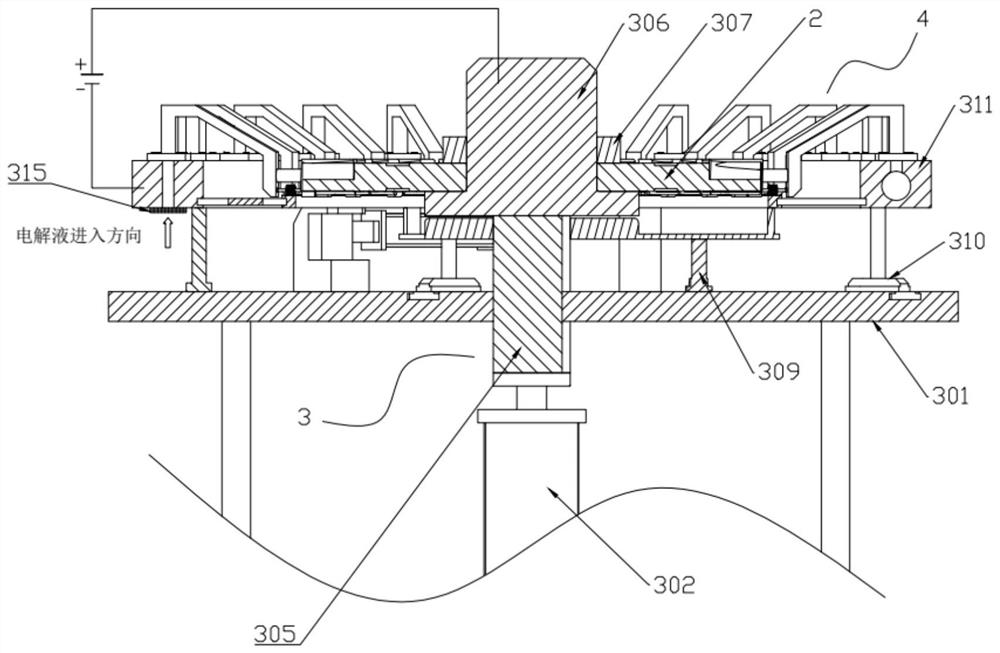

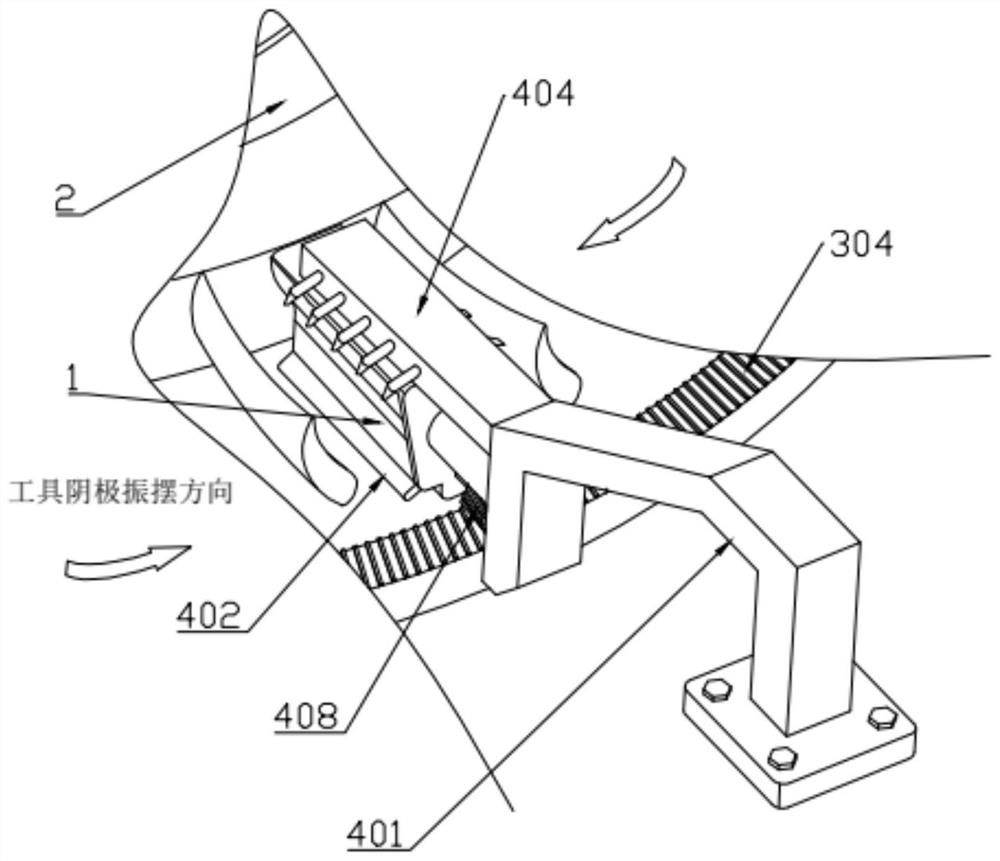

[0031] like Figure 1 to Figure 8 As shown, a method for adaptive processing of leading and trailing edges of aero-engine turbine blades includes the following steps:

[0032] S1: Electrode selection: According to the blade profile on the integral impeller 2 to be precisely machined, select the tool cathode 1, and the two sides of the tool cathode 1 are respectively offset with the blade basin and the blade back of the blade by equal amounts;

[0033] S2: Preprocessing before processing: check whether there are protrusions or depressions on the surface of the variable-section blade of the integral impeller 2, and use absolute ethanol to clean the variable-section blade and tool cathode 1 for the first time after the inspection;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com