Ceramic shutter preparation device with homogenized surface nano coating

A technology for preparing devices and nano-coatings, which is applied to devices, coatings, and special surfaces for coating liquid on the surface, which can solve the problem of aesthetics and other performance degradation, affecting the surface cleaning of pottery louvers, and affecting the formation rate of nano-layers and other problems, to achieve the effect of reducing the phenomenon of hanging liquid, improving the spraying effect and improving the aesthetics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

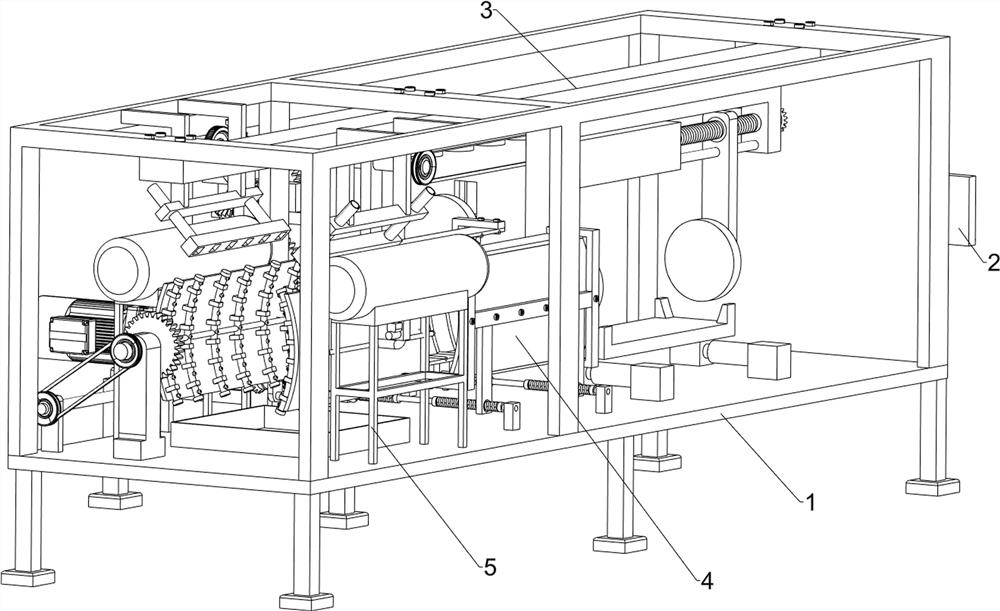

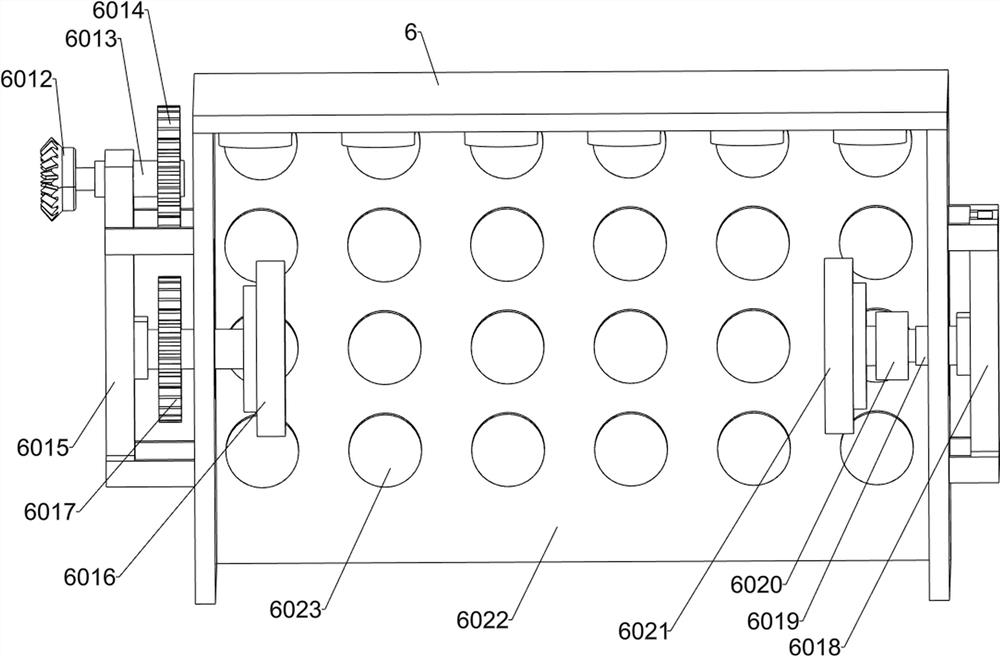

[0031] A pottery louver preparation device for uniform surface nano-coating, such as Figure 1-10 As shown, it includes a support chassis 1, a controller 2, a clamping and conveying system 3, a surface cleaning system 4, a nano-layer spraying system 5 and a drying system 6; the support chassis 1 is connected with the controller 2; the support chassis 1 is sequentially connected with the clamping conveying system 3, surface cleaning system 4 and nano-layer spraying system 5; the support chassis 1 is connected with the drying system 6; the clamping conveying system 3 is connected with the drying system 6; nano-layer spraying System 5 is connected to drying system 6 .

[0032] Working principle: Before the operation of the device, install and fix the support chassis 1 in the device on a stable working place, connect the external power supply, and the operator manually operates the controller 2 to start the device, check the running transmission between the systems, and confirm th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com