A polyvinylidene fluoride separation membrane and its preparation method and application in sewage treatment

A polyvinylidene fluoride and separation membrane technology, applied in the field of membrane separation, can solve the problems of poor hydrophilicity, easy adsorption of organic pollutants, and shortened service life of polyvinylidene fluoride separation membranes, so as to improve hydrophilicity and anti-pollution performance, improve pure water flux, and prolong service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

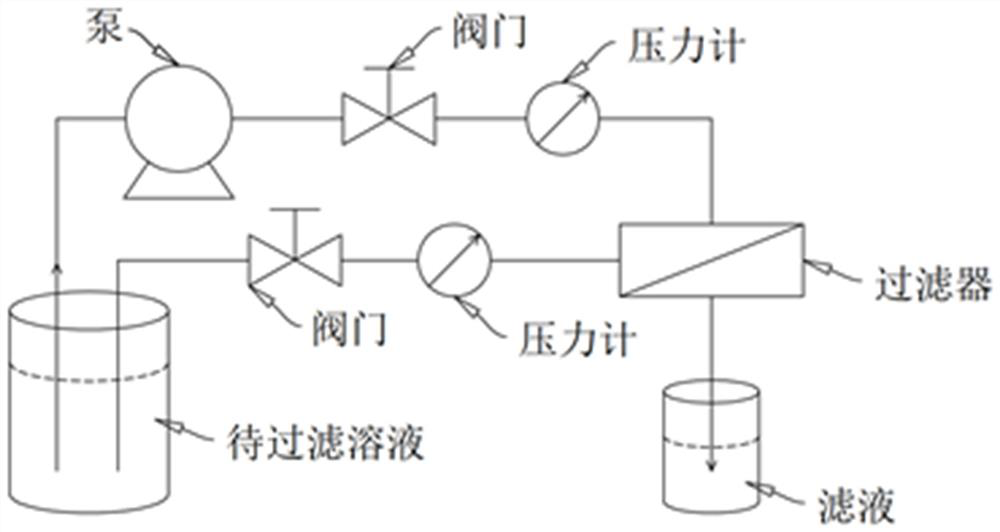

Image

Examples

Embodiment Construction

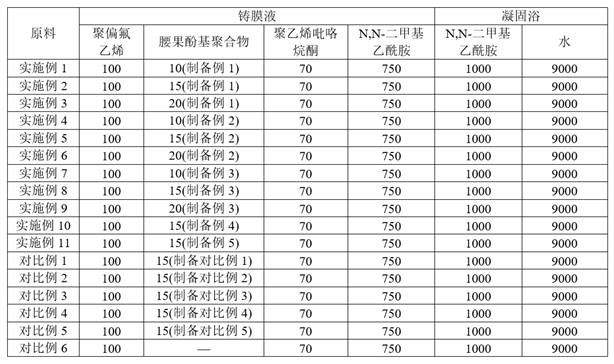

[0024] The present application will be described in further detail below in combination with specific embodiments.

[0025] The polyvinylidene fluoride in the following examples and comparative examples is FR904 polyvinylidene fluoride; the weight percentage concentration of the formaldehyde solution is 37%.

[0026] Preparation example of cardanol-based polymer

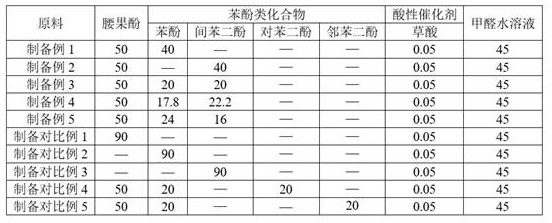

[0027] Table 1 The ingredient list of cardanol-based polymer (unit: g)

[0028]

[0029] The specific preparation method of the above-mentioned cardanol-based polymer is: add cardanol, phenol, oxalic acid to a four-necked round-bottomed flask equipped with a stirrer, a thermometer, a reflux condenser and a dropping funnel, heat to 95 ° C, and then Add dropwise formaldehyde solution with a concentration of 37% by weight within 1 hour, and continue to keep warm for 3 hours after the dropwise addition; cool down to room temperature, soak in water at 50-60°C for 30 minutes and repeat 10 times, and dry to obtain carda...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com