Production method of sulpiride preparation

A production method and sulpiride technology, applied in the production field of sulpiride preparations, can solve problems such as slow dissolution rate, and achieve the effects of good smoothness and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

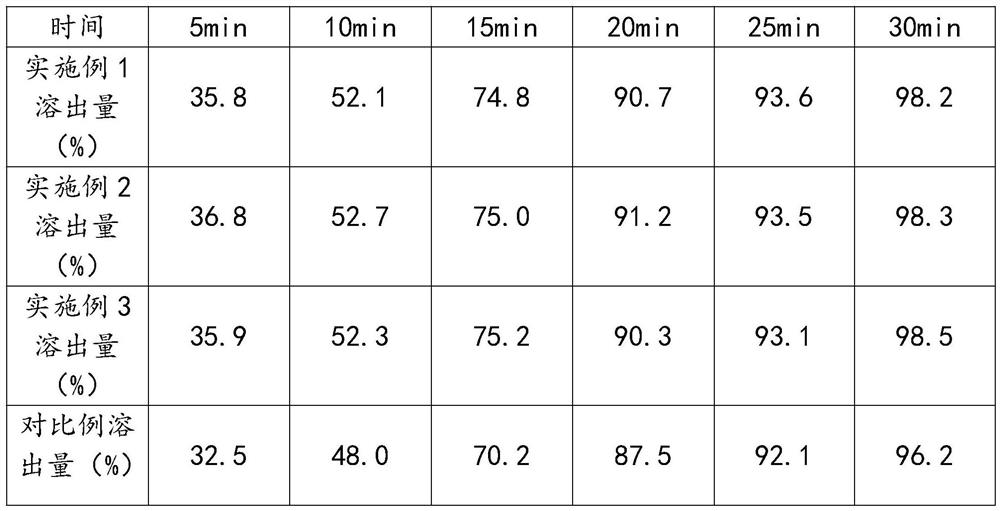

Examples

Embodiment 1

[0026] A production method of a sulpiride preparation, the sulpiride preparation comprises the following raw materials in parts by weight: 5 parts of sulpiride, 3 parts of lactose, 3.17 parts of microcrystalline cellulose, 0.19 parts of croscarmellose sodium, 0.21 parts of a disintegrant, talc 0.15 parts, 0.28 parts of magnesium stearate, 4.95 parts of purified water;

[0027] The production method of this sulpiride preparation comprises the steps:

[0028] Step S1: Weighing: Under the conditions of indoor temperature of 17°C and humidity of 30%, use a platform scale to accurately weigh the raw materials by weight, and wait for use after the weighing is completed;

[0029] Step S2: Prepare the binding solution: add the weighed purified water into the cleaned and dried pulping tank under the conditions of the indoor temperature of 17°C and the humidity of 30%, then add the disintegrating agent into the purified water, at a speed of 200r / min, stirring at a temperature of 20°C ...

Embodiment 2

[0037] A production method of a sulpiride preparation, the sulpiride preparation comprises the following raw materials in parts by weight: 10 parts of sulpiride, 6 parts of lactose, 6.34 parts of microcrystalline cellulose, 0.38 parts of croscarmellose sodium, 0.42 parts of a disintegrant, talc 0.3 parts, 0.56 parts of magnesium stearate, 9.9 parts of purified water;

[0038]The production method of this sulpiride preparation comprises the steps:

[0039] Step S1: Weighing: under the conditions of indoor temperature of 21.5°C and humidity of 50%, accurately weigh the raw materials by weight on a platform scale, and wait for use after the weighing is completed;

[0040] Step S2: Prepare the binding solution: Add the weighed purified water into the cleaned and dried pulping tank under the condition of the indoor temperature of 21.5°C and the humidity of 50%, then add the disintegrating agent into the purified water, at a speed of 200r / min, stirring at a temperature of 25°C unt...

Embodiment 3

[0048] A production method of a sulpiride preparation, the sulpiride preparation comprises the following raw materials in parts by weight: 15 parts of sulpiride, 9 parts of lactose, 9.51 parts of microcrystalline cellulose, 0.57 parts of croscarmellose sodium, 0.63 parts of a disintegrant, talc 0.45 parts, 0.84 parts of magnesium stearate, 14.85 parts of purified water;

[0049] The production method of this sulpiride preparation comprises the steps:

[0050] Step S1: Weighing: Under the conditions of indoor temperature of 27°C and humidity of 70%, use a platform scale to accurately weigh raw materials by weight, and wait for use after the weighing is completed;

[0051] Step S2: Prepare the binding solution: Add the weighed purified water into the cleaned and dried pulping tank under the condition that the indoor temperature is 27°C and the humidity is 70%. / min, stirring at a temperature of 30°C until the disintegrating agent is completely dissolved to obtain a combined sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com