Coffee roasting method, coffee powder and capsule beverage

A roasting method and coffee technology, applied in the field of coffee powder and capsule beverages and coffee roasting, can solve the problems of destroying the purity of coffee, affecting human health, and increasing the cost of equipment investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

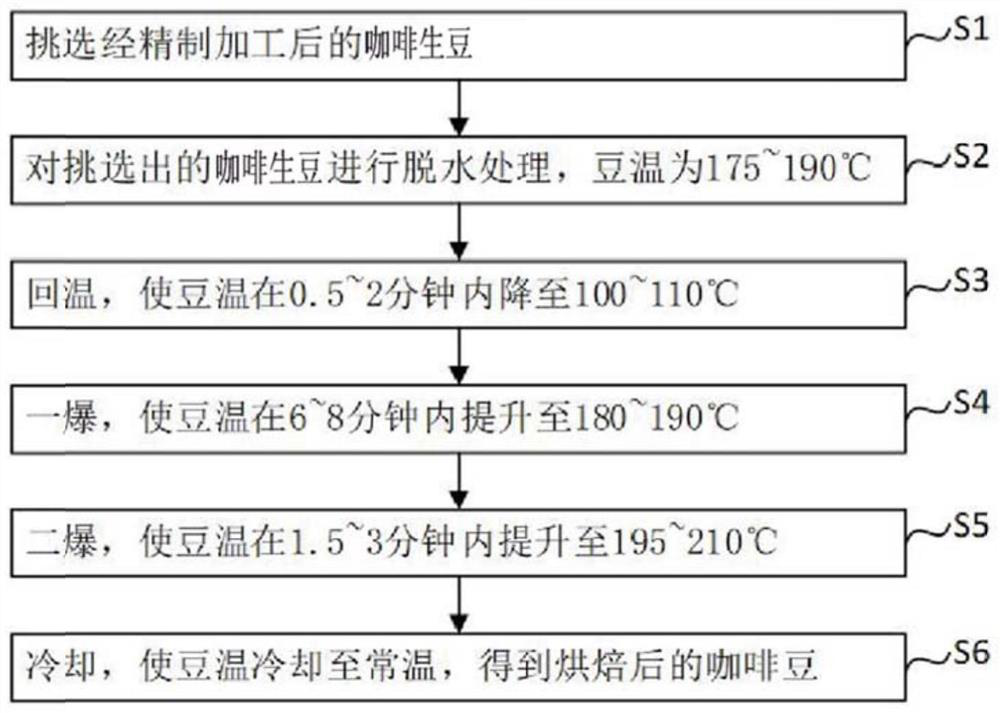

Method used

Image

Examples

Embodiment 1

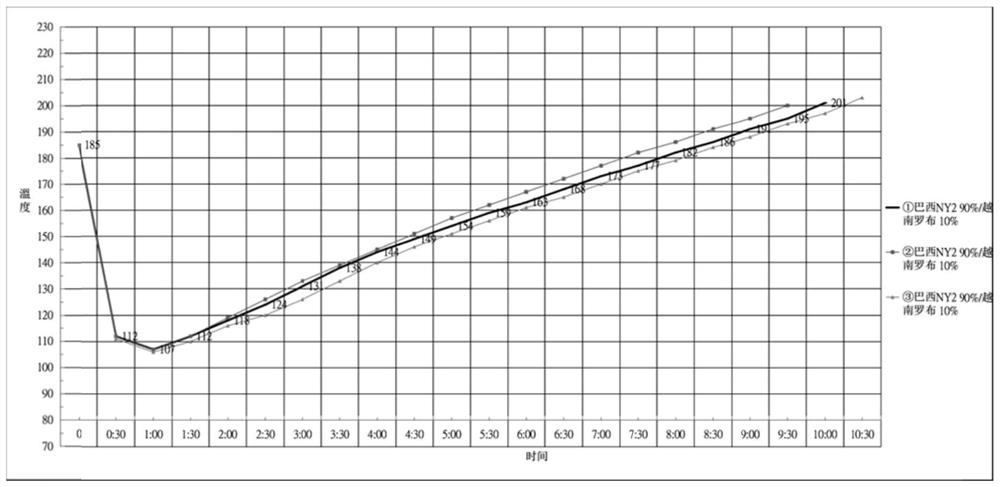

[0080] In this example, the refined and processed Brazilian NY2 green coffee beans and Vietnamese Robe coffee beans were selected; and the Brazilian NY2 green coffee beans and Vietnamese Robe coffee beans were mixed at a weight of 8:1 to 10:1 to obtain Blended green coffee beans. Specifically, in this embodiment, Brazilian NY2 green coffee beans with a weight ratio of 9:1 and Vietnamese Robus green coffee beans are mixed to obtain mixed green coffee beans.

[0081] First, the selected green coffee beans are dehydrated, and the temperature of the beans is 185±2°C, specifically, 185°C.

[0082] Next, warm up the coffee beans so that the temperature of the beans drops to 106-108°C within 1-2 minutes. During the temperature recovery process, the bean temperature dropped rapidly to about 110°C in the first 30 seconds, and then stabilized at around 107°C in the last 30 seconds to 60 seconds, and the temperature recovery was completed at this time.

[0083] Then, directly crack the...

Embodiment 2

[0106] In this example, refined and processed Yunnan AA green coffee beans, Yunnan Sun-dried G1 green coffee beans, New Oriental green coffee beans, Guatemala SHB green coffee beans and Peruvian green coffee beans were selected.

[0107]The Yunnan AA green coffee beans with a weight percentage of 16±2%, the Yunnan sun-dried G1 green coffee beans with a weight percentage of 14±2%, the New Oriental coffee beans with a weight percentage of 24±3%, and a weight percentage of 24±3 % Guatemalan SHB green coffee beans and Peruvian green coffee beans with a weight percentage of 22±2% are mixed to obtain mixed green coffee beans. Specifically, in this embodiment, 16% by weight of Yunnan AA green coffee beans, 14% by weight of Yunnan sun-dried G1 green coffee beans, 24% by weight of New Oriental coffee green beans, and 24% Guatemalan SHB green coffee beans and 22% Peruvian green coffee beans by weight are mixed to obtain mixed green coffee beans.

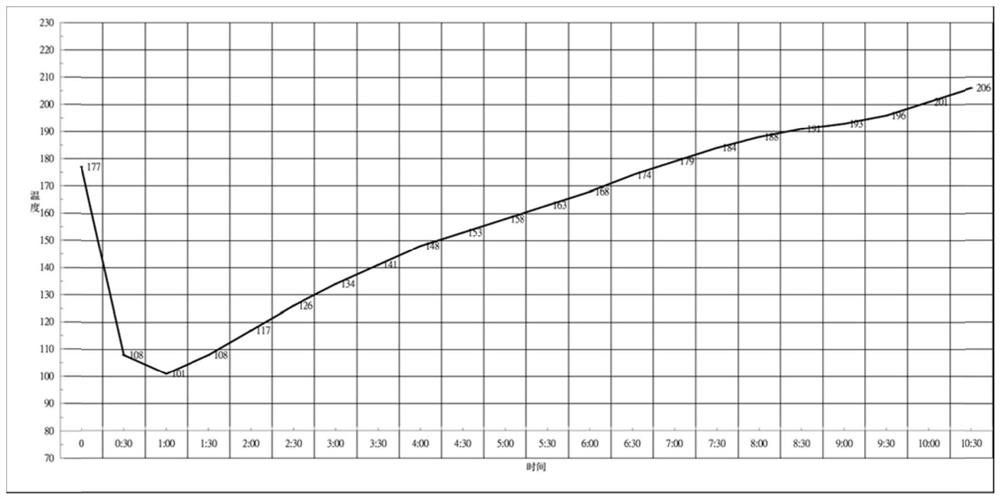

[0108] First, the selected green coffe...

Embodiment 3

[0120] In this embodiment, different from Embodiment 1 and Embodiment 2, the green coffee beans in this embodiment have only one ingredient, which is refined Colombian green coffee beans.

[0121] First, the selected green coffee beans are dehydrated, and the temperature of the beans is 185±2°C, specifically, 185°C.

[0122] Next, warm up the coffee beans so that the temperature of the beans drops to 104-109°C within 1-1.5 minutes. During the temperature recovery process, the bean temperature dropped rapidly to around 110°C in the first 30 seconds, and then stabilized at around 106°C in the last 30 seconds to 60 seconds, and the temperature recovery was completed at this time.

[0123] Then, directly crack the coffee beans at the rewarming temperature to increase the temperature of the beans to 181-185°C within 7-8 minutes. In this embodiment, the temperature rise of the first explosion is a constant speed process, which is stable at 12-14° C. / min. The firepower of the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com