Curable film

A curable, curable composition technology, applied in the direction of electrical solid devices, semiconductor/solid device manufacturing, semiconductor/solid device components, etc., can solve problems such as cracks, poor thermal expansion coefficient, package warpage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0197] Preparation Example 1: Preparation of Support (Preparation of Cellulose Nonwoven Fabric)

[0198] Dilute the slurry of microfiber CELISH KY110N (manufactured by Daicel Co., Ltd.) to 0.2% by weight, and use a paper machine with a decompression device (manufactured by Toyo Seiki Co., Ltd., standard square machine) to filter No.5C Papermaking was carried out as a filter cloth to obtain a cellulose nonwoven fabric in a wet state.

[0199]Blotting papers were stacked on both sides of the obtained cellulose nonwoven fabric in a wet state, and pressed at a pressure of 0.2 MPa for 1 minute. Next, pressurize with a pressure of 0.2 MPa for 1 minute, then paste it on a drum dryer (manufactured by Kumagai Riki Kogyo Co., Ltd.) with a surface temperature of 100° C., and dry for 120 seconds to obtain a cellulose nonwoven fabric ( Porosity: 60vol%, weight per unit area: 9.9g / m 2 , Linear thermal expansion coefficient: 5ppm / K, thickness 25μm).

Embodiment 1~7

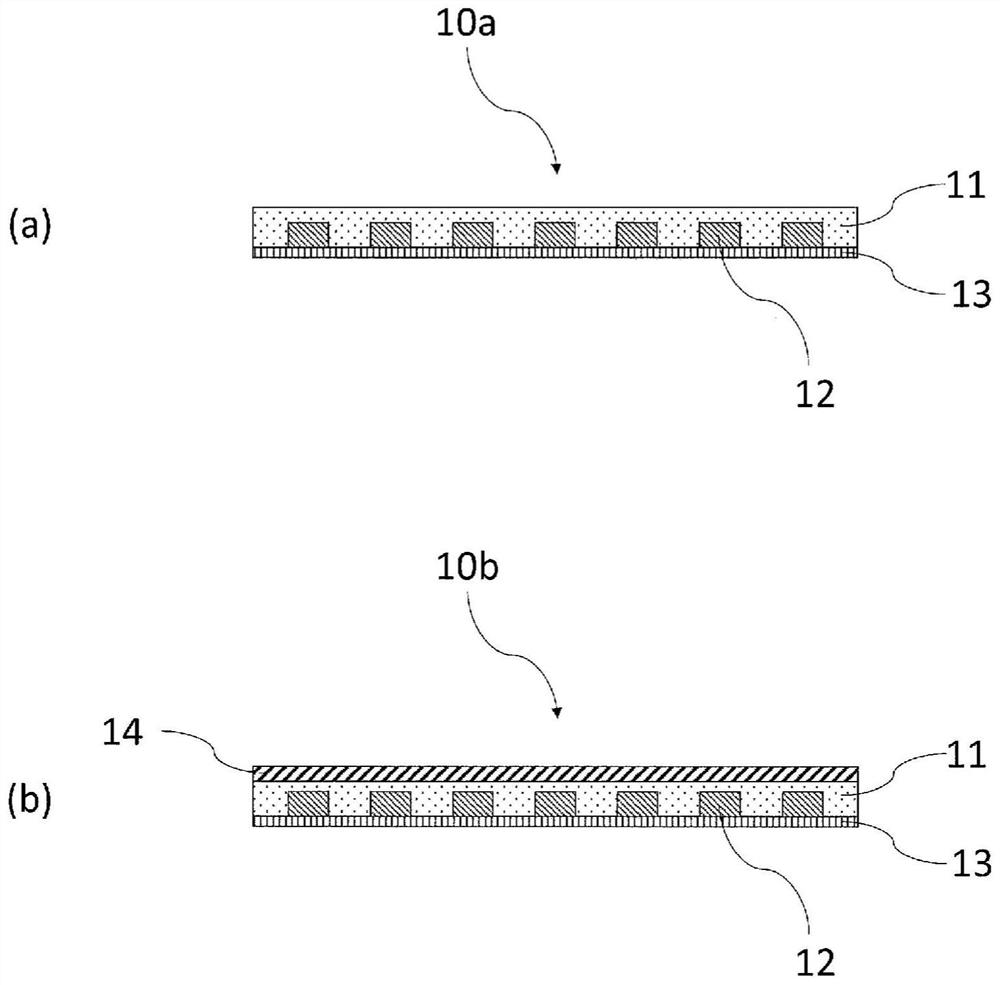

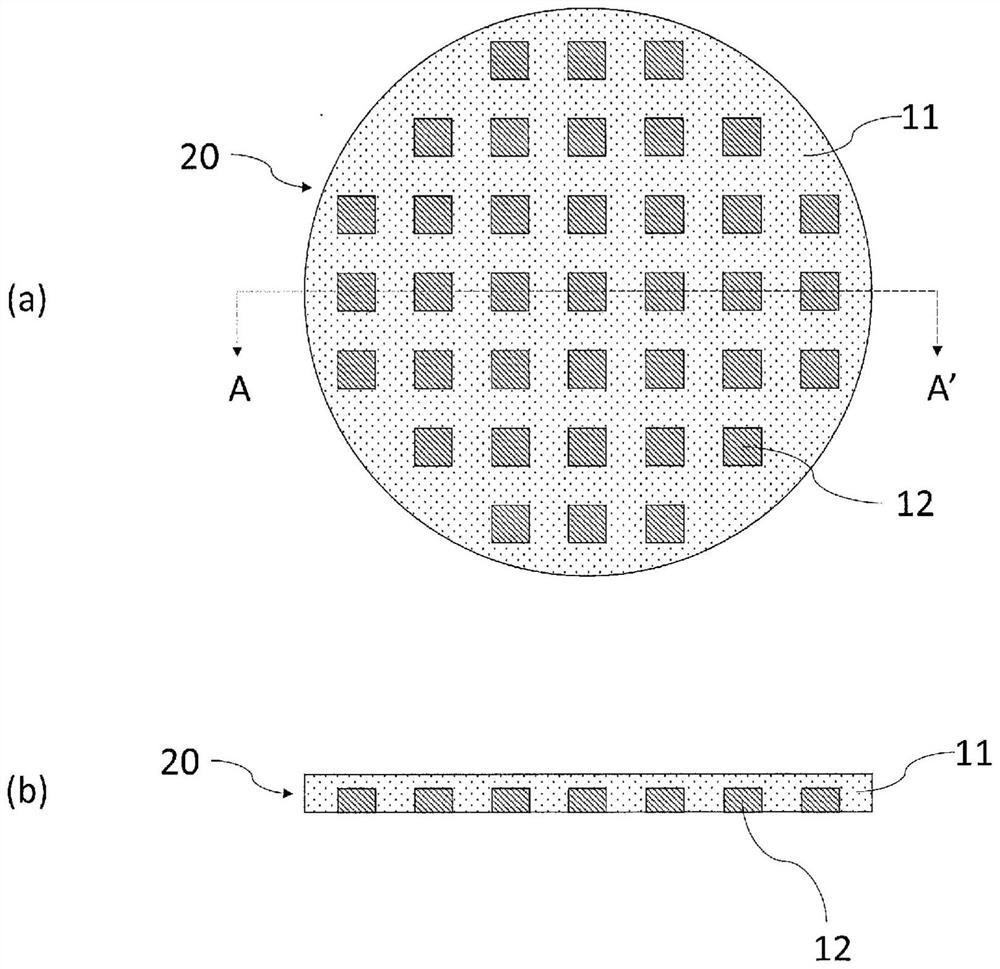

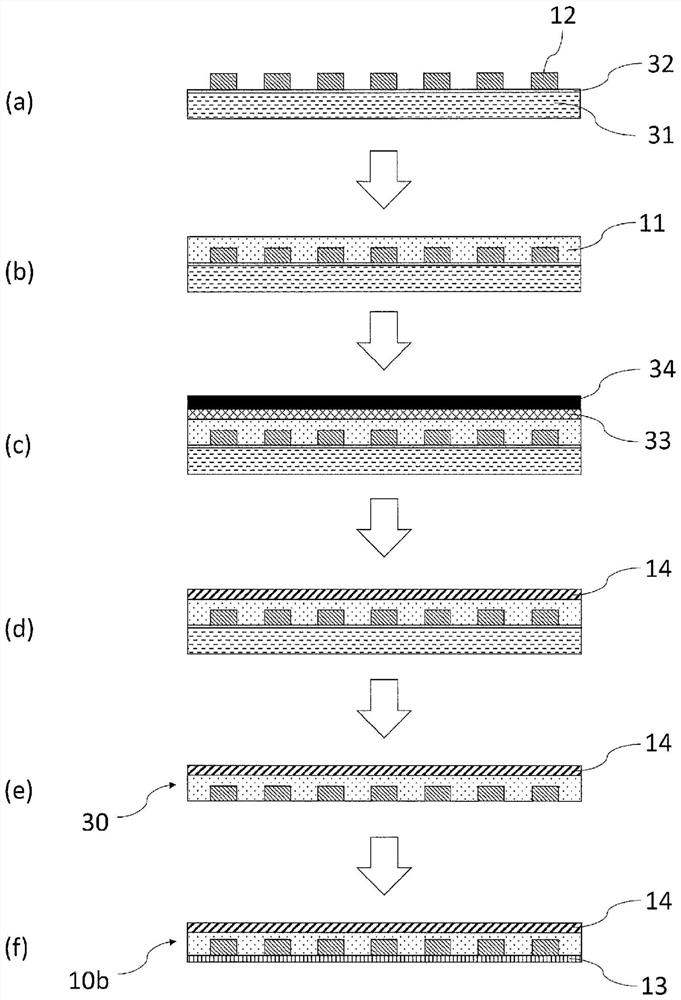

[0201] (Preparation of curable film)

[0202] Curable compositions were prepared according to the recipes described in Table 1.

[0203] After immersing the cellulose nonwoven fabric obtained in Preparation Example 1 in the above-obtained curable composition under reduced pressure, solvent removal under reduced pressure and impregnation with the curable composition again were performed to produce cured permanent film (ratio of curable composition: 65vol%).

[0204] The obtained curable film was cured under the curing conditions shown in Table 1, and the glass transition temperature and linear thermal expansion coefficient of the obtained cured product were measured by the following method. The results are shown in Table 1.

[0205] (production of sealing material)

[0206] Add bisphenol A glycidyl ether (YD128) 100g, RIKACID MH-700F 87g, ethylene glycol 2g and curing accelerator (U-CAT 12XD) 0.5g, use the rotation / revolution vacuum mixer (trade name "Awatori Rentaro", THIN...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

| Porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com