Liquid recoil arc extinguishing and lightning protection method

An arc-extinguishing, liquid-state technology, applied in the field of electronics, can solve problems such as damage to insulator strings and hardware, breakage, and inability to carry out power transmission work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the object, technical solution and advantages of the present invention clearer, preferred embodiments are given to further describe the present invention in detail. However, it should be noted that many of the details listed in the specification are only for readers to have a thorough understanding of one or more aspects of the present invention, and these aspects of the present invention can be implemented even without these specific details.

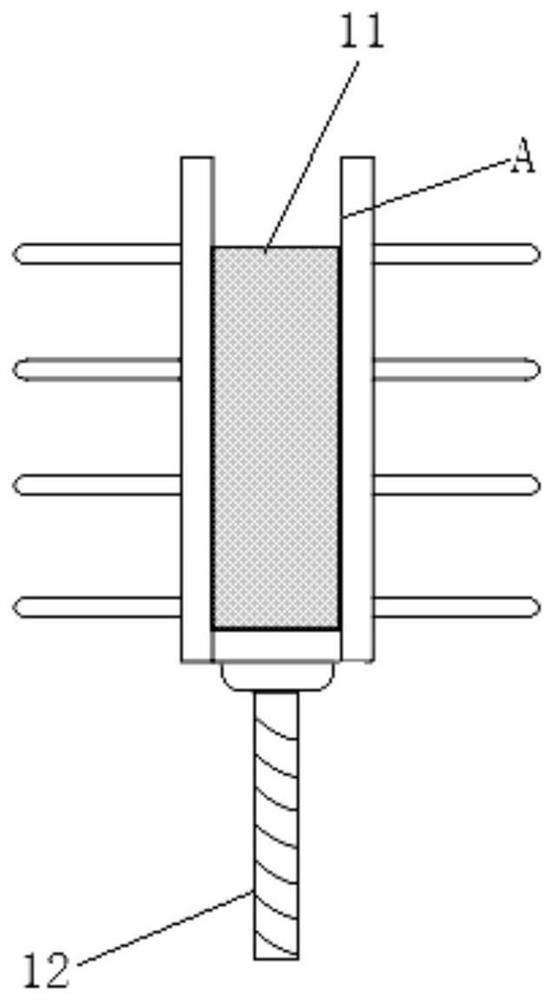

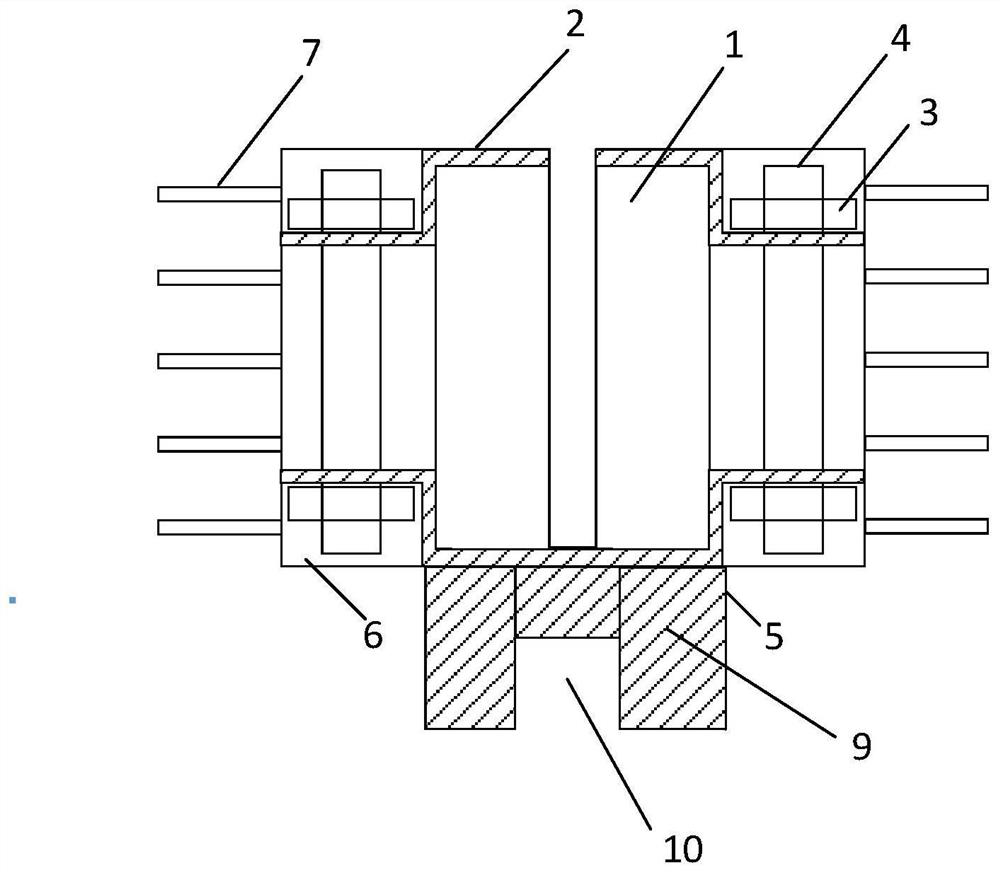

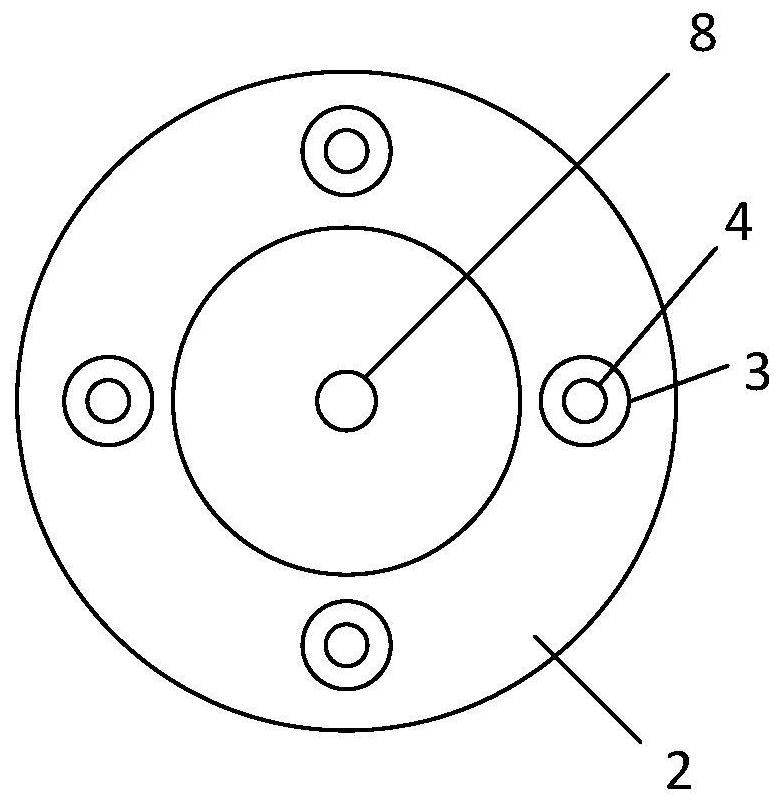

[0028] A liquid recoil arc extinguishing lightning protection method, such as figure 1 As shown, the liquid 11 is placed in the recoil tube A. When the arc enters the recoil tube A, the moment the arc pre-breaks through the liquid 11, due to the extremely short impact time of the lightning arc, the liquid cannot be deformed and displaced instantaneously, and the liquid Electric detonation effect, the recoil arc extinguishing pressure peak is synchronized with the impact steepness arc pre-breakdown time, the impa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com