CSP online die bonder

A die-bonding machine and die-bonding technology, used in electrical components, circuits, semiconductor devices, etc., can solve the problems of equipment jitter, poor stability, and large equipment size, and achieve the effects of reducing vibration, high stability, and reducing operation difficulty.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

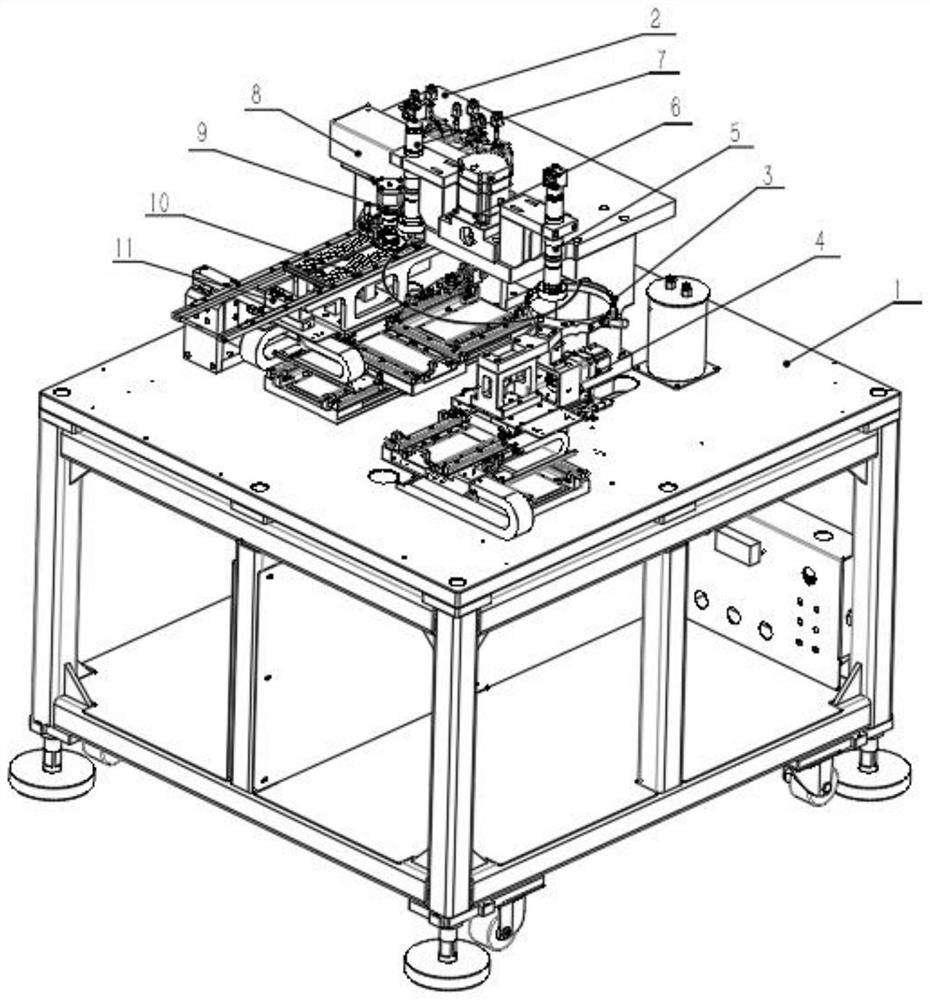

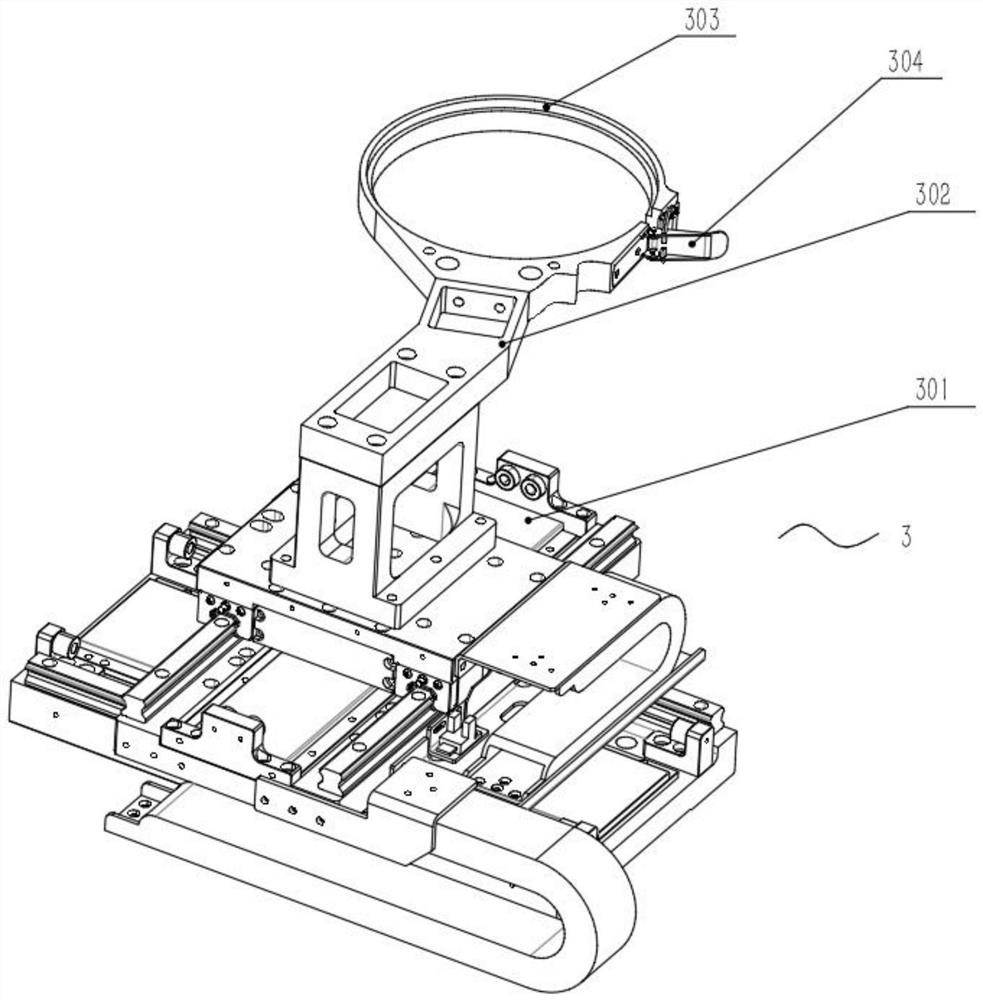

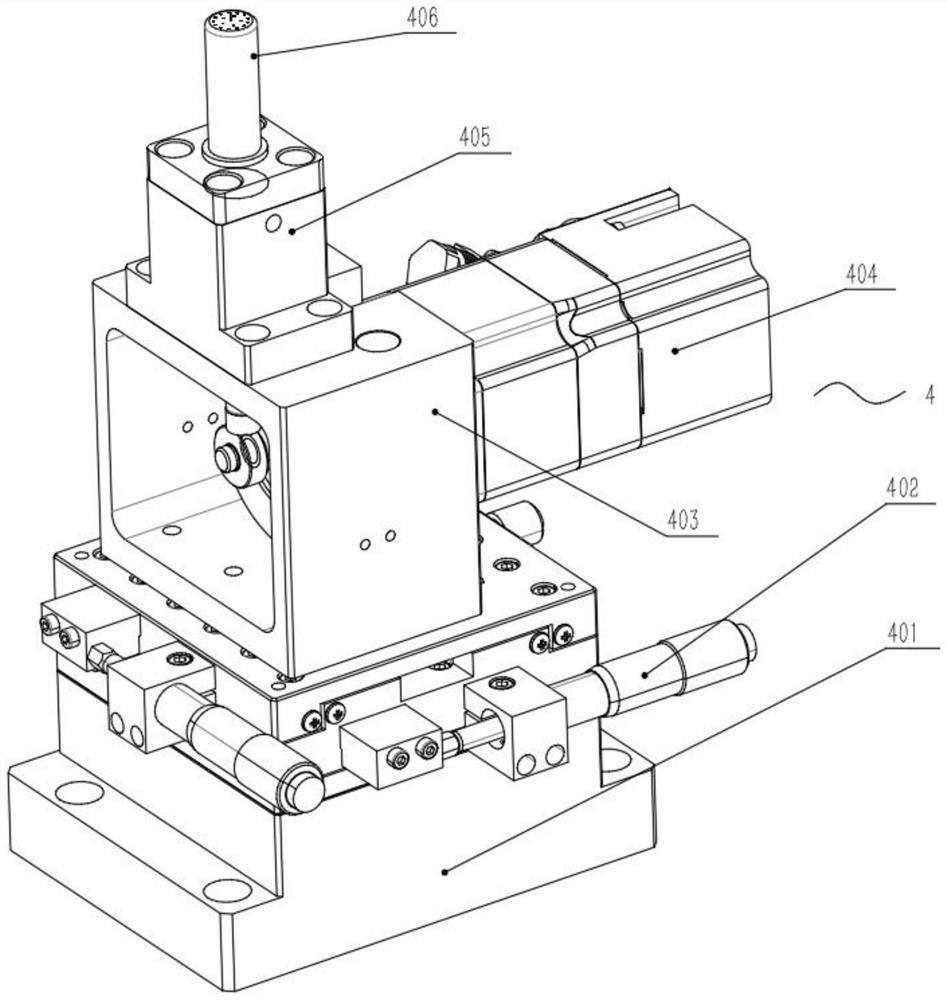

[0045] see Figure 1-11 , in the embodiment of the present invention, the CSP online crystal bonding machine includes a frame 1, a gantry frame 2, a wafer assembly 3, a thimble assembly 4, a feeding vision assembly 5, a swing arm assembly 6, a crystal bonding vision assembly 7, and a dispensing Component 8 , glue supply component 9 , die bonding component 10 and material supply positioning component 11 . The frame 1 plays a supporting role, the gantry 2 is fixed on one side of the top surface of the frame 1 , and the wafer assembly 3 is fixed on the top surface of the frame 1 and is located on one side of the gantry 2 . The thimble assembly 4 is fixed on one side of the wafer assembly 3 . The feeding visual assembly 5 is located above the wafer assembly 3 and is fixedly connected with the gantry 2 . The swing arm assembly 6 is located on one side of the loading vision assembly 5 and is fixedly connected with the gantry 2 . The crystal-bonding visual assembly 7 is located on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com