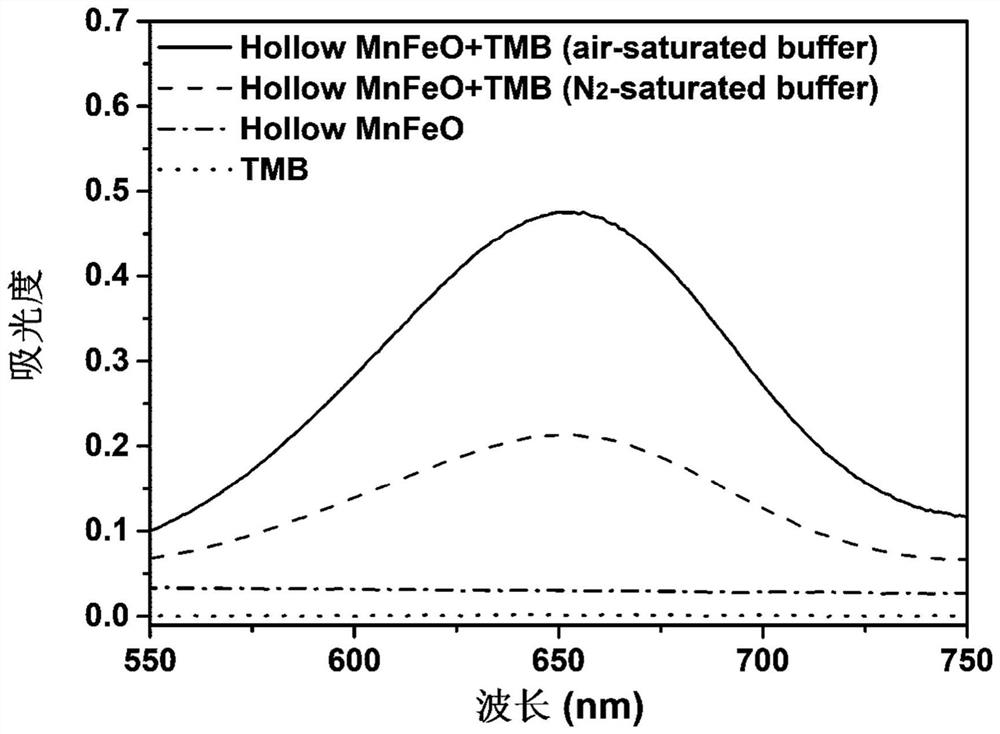

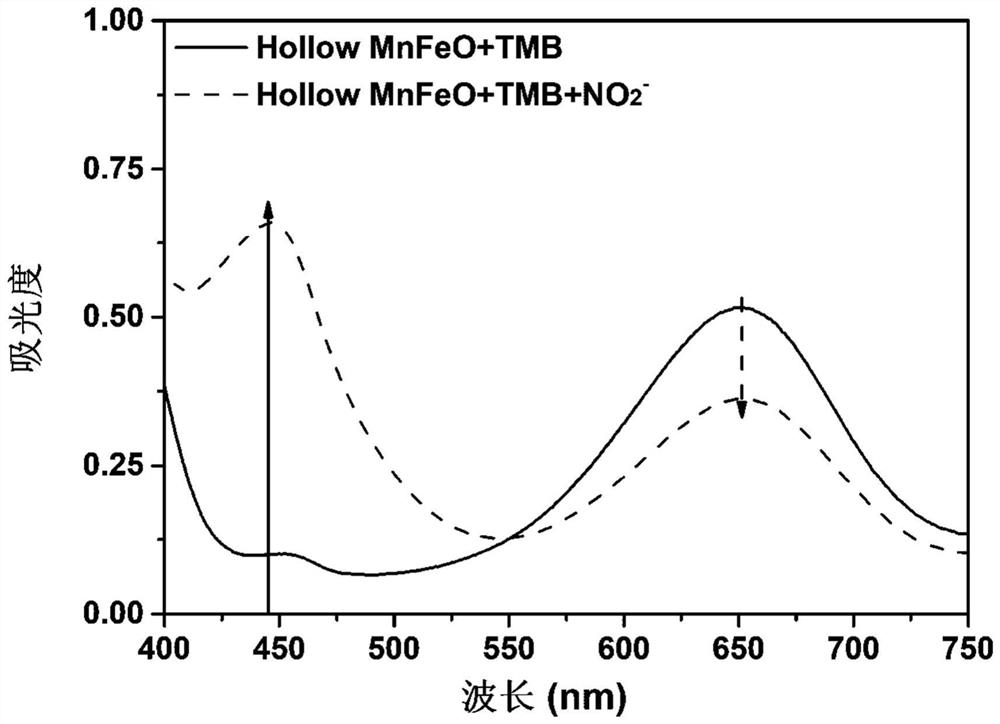

Method for detecting nitrite ions based on ratio-type colorimetry

A nitrite ion, ratio-based technology, applied in the field of analytical chemistry, can solve the problems of expensive detection equipment, complex detection method operation, high cost of detection reagents, etc., and achieve the effect of low detection cost, simple operation and rapid detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] (1) Add 0.0187mmol Fe 2 (SO 4 ) 3 with 0.373mmol MnSO 4 ·H 2 O dissolved in 0.3g PVP, 10mL LC 2 h 5 OH, 10mL deionized water mixed solution, ultrasonic 15min, after stirring for 10min, 10mL20mM K 3 [Fe(CN) 6 ] slowly added dropwise to Fe 2 (SO4) 3 with MnSO 4 ·H 2 In the mixed solution of O, continue to stir at room temperature for 1 h, then centrifuge the mixture at a speed of 8000 r / min, wash with ethanol and deionized water for 3 times, and finally freeze-dry to obtain Mn / Fe PBA;

[0046] (2) Dissolve 0.1g of Mn / Fe PBA in the above step (1) in 15mL of deionized water, add 10mL of 6mM TGA and stir at room temperature for 3h after ultrasonication for 20min, then centrifuge the mixture at a speed of 8000r / min, and then use Wash with ethanol and deionized water three times each, and finally freeze-dry to obtain hollow Mn / Fe PBA;

[0047] (3) Take an appropriate amount of hollow Mn / Fe PBA in step (2) and heat it in a tube furnace at 2.0°C min -1 Raise the tem...

Embodiment 2

[0052] (1) 0.048mmol Fe 2 (SO 4 ) 3 with 0.373mmol MnSO 4 ·H 2 O dissolved in 0.6g PVP, 20mL LC 2 h 5 OH, 20mL deionized water mixed solution, ultrasonic 15min, after stirring for 10min, 20mL 20mM K 3 [Fe(CN) 6 ] Slowly added dropwise to Fe 2 (SO4) 3 with MnSO 4 ·H 2 In the mixed solution of O, continue to stir at room temperature for 1 h, then centrifuge the mixture at a speed of 8000 r / min, wash with ethanol and deionized water for 3 times, and finally freeze-dry to obtain Mn / Fe PBA;

[0053] (2) Dissolve 0.1g of Mn / Fe PBA in the above step (1) in 25mL of deionized water, add 15mL of 6mM TGA after ultrasonication for 20min and stir at room temperature for 6h, then centrifuge the mixture at a speed of 8000r / min, and then use Wash with ethanol and deionized water three times each, and finally freeze-dry to obtain hollow Mn / Fe PBA;

[0054] (3) Take an appropriate amount of hollow Mn / Fe PBA in step (2) and heat it in a tube furnace at 2.0°C min -1 Raise the tempera...

Embodiment 3

[0059] (1) 0.187mmol Fe 2 (SO 4 ) 3 with 0.373mmol MnSO 4 ·H 2 O dissolved in 0.9g PVP, 30mLLC 2 h 5 OH, 30mL deionized water mixed solution, ultrasonic 15min, after stirring for 10min, 30mL 20mM K 3 [Fe(CN) 6 ] slowly added dropwise to Fe 2 (SO4) 3 with MnSO 4 ·H 2 In the mixed solution of O, after continuing to stir at room temperature for 1 h, the mixture was centrifuged at a speed of 8000 r / min, washed with ethanol and deionized water for 3 times, and finally freeze-dried to obtain Mn / Fe PBA;

[0060] (2) Dissolve 0.1g of Mn / Fe PBA in the above step (1) in 35mL of deionized water, add 20mL of 6mM TGA after ultrasonication for 20min and stir at room temperature for 9h, then centrifuge the mixture at a speed of 8000r / min, and then use Wash with ethanol and deionized water three times each, and finally freeze-dry to obtain hollow Mn / Fe PBA;

[0061] (3) Take an appropriate amount of hollow Mn / Fe PBA in step (2) and heat it in a tube furnace at 2.0°C min -1 Raise ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com