Quick-frozen ball production equipment

A technology for producing equipment and quick-freezing balls, applied in lighting and heating equipment, ice manufacturing, ice making, etc., can solve the problems of increased product cost, complicated production process of freeze-dried balls, and large demand for personnel, and achieves consistency, Ingenious design and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

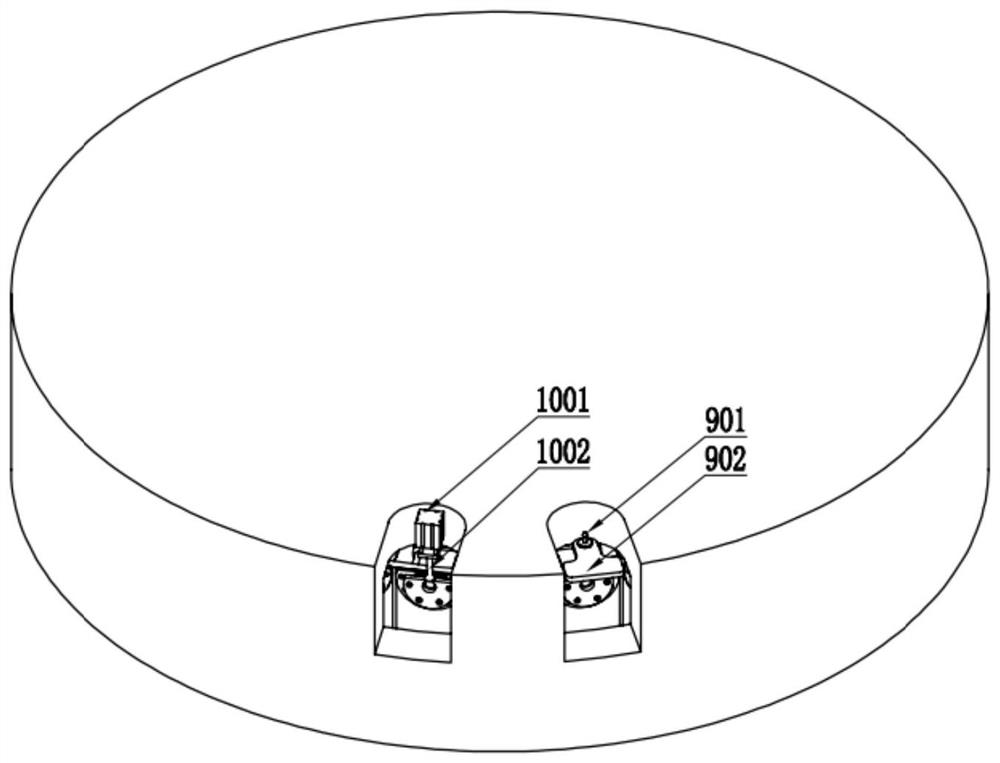

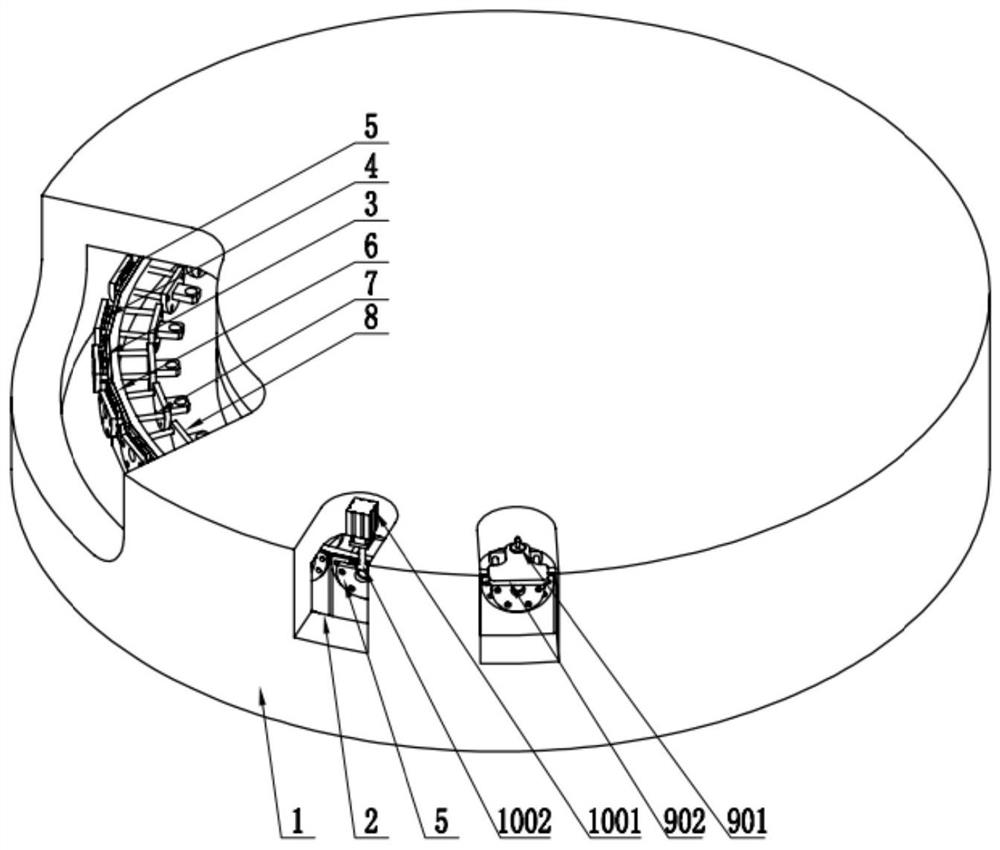

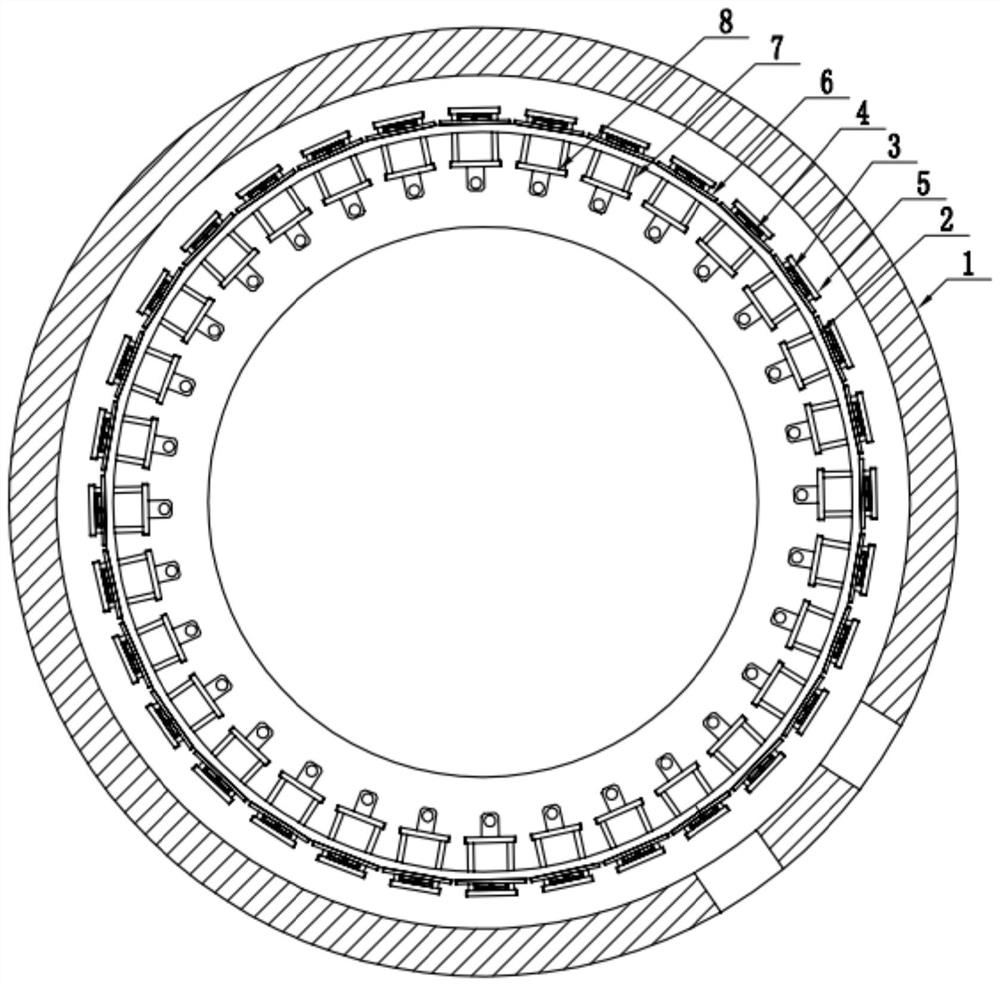

[0022] This embodiment is a frozen pellet production equipment, such as figure 2 Shown, including a frozen box; rotating platform (or mesh belt; guide, etc.) 2; front mold 3; 4 after mold; front mounting plate 5; rear mounting plate 6; die pusher 7; 8 fixed plate; filling means 9; 10 to push the ball mechanism.

[0023] Rotating platform (or mesh belt, rails, etc.) installed in the frozen tank 2 1, and can turn in a frozen box; frozen ball mold 2 mounted on a rotating platform.

[0024] When the current mold 3 and mold 4 is moved to the filling position, the push rod 7 causes the mold before the mold die 4, and 3 were combined, two hemispherical recesses 301, 401 form a spherical cavity of the mold, filling the needle before 901, the cutout 302, 402 of the mold cavity is formed is spherical liquid filling, after filling the mold with the rotating platform (or mesh belt, rails, etc.) to the second rotating tank a cavity frozen, frozen box an internal low-temperature gas, after fill...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com