On-site grouting system and method for reinforcing flocculated sludge by combining vacuum preloading and grouting

A grouting system and on-site technology, applied in the field of geotechnical engineering and hydraulic engineering research, can solve problems such as complex construction, long time, and reduced vacuum preloading effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be described in further detail below with reference to the accompanying drawings and embodiments. Wherein the same parts are denoted by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to directions in the drawings, and the words "bottom" and "top" "Face", "inner" and "outer" refer to directions toward or away from the geometric center of a particular part, respectively.

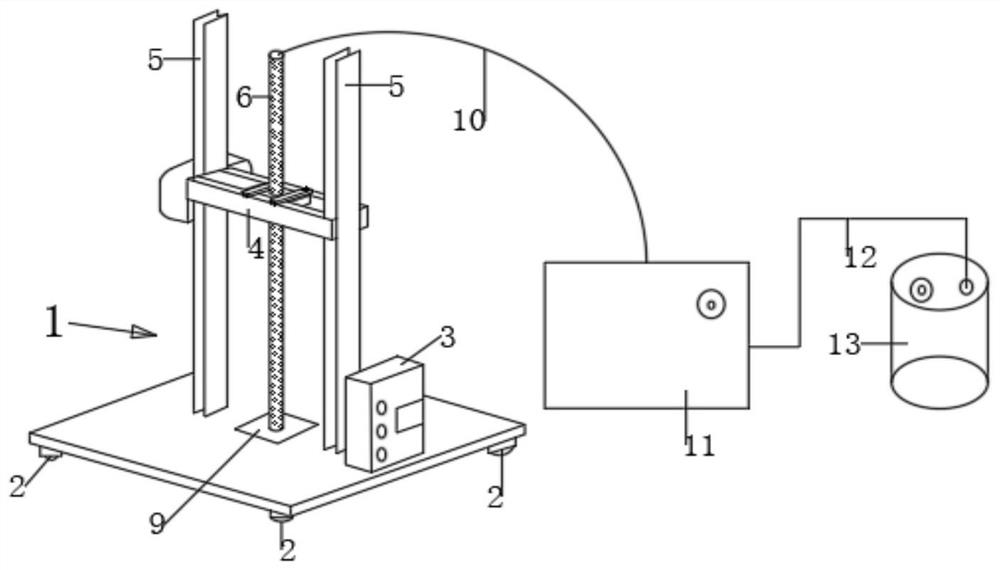

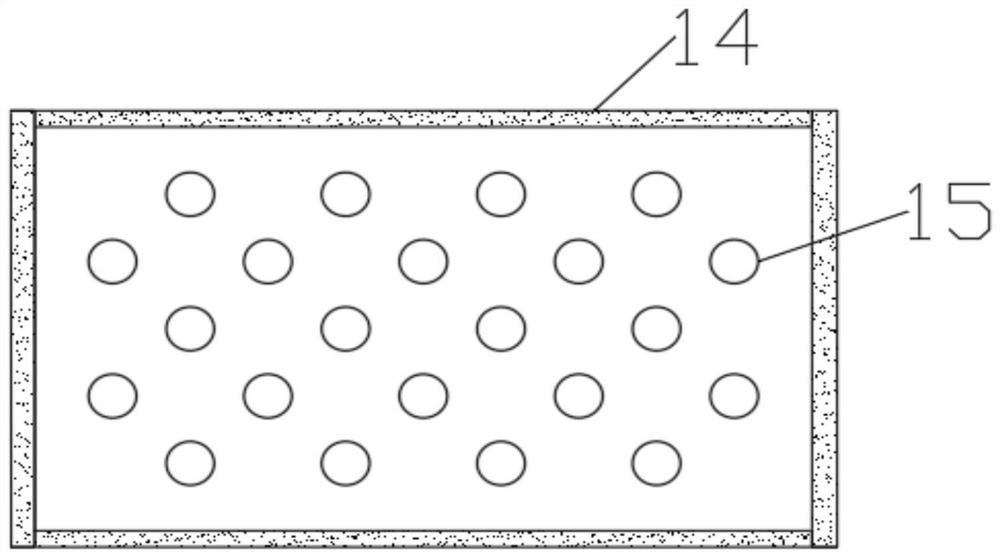

[0043] refer to Figure 1-4 As shown, the on-site grouting system provided in Embodiment 1 of the present invention includes a movable construction machinery vehicle 1, a flocculant pump 11 and a flocculant stirring tank 13, and the construction machinery vehicle 1 includes a mobile platform 1a with a driving wheel 2, A platform grouting port 9 is arranged in the middle of the mobile platform 1a, and a loading frame is arranged on the mobile platform 1a. The loading ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com