Denim flexible warp sizing slurry and method

A warp sizing and fabric flexibility technology, applied in the direction of wear-resistant fiber, plant fiber, fiber treatment, etc., can solve the problems of high cost and environmental protection, and achieve high uniformity, desizing energy saving, water saving, and stable viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

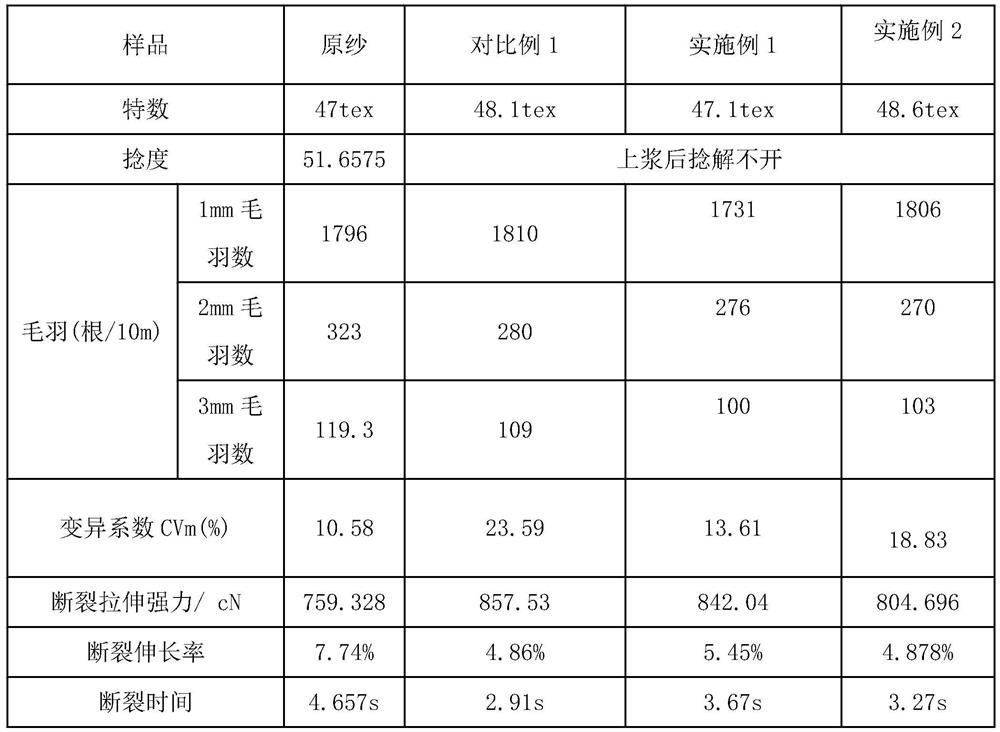

Embodiment 1

[0019] Yarn variety: Zhongchao Textile 968 of Zhonghua Spinning Mill, color: SG extra dark blue, yarn count 9.8S Zhonghua Slub, total yarn count 4400, total length 15300m, speed 25.8m / min.

[0020] The technological process is yarn cooking → multi-cylinder indigo dyeing and oxidation → multiple washings → sizing → drying → yarn separation → reel (finished product). Among them, in the multi-cylinder indigo dyeing and oxidation, two dipping and two padding methods are used for sizing, that is, dyeing and then padding, and then dyeing and padding again, repeating twice. Sizing temperature: 95°C, size tank volume 1100L.

[0021] The base slurry is 1100L. The raw materials include 135kg starch and 109.5kg multi-component copolymer rubber compound. In addition, it also includes 4KG wax oil, 6KG palmitic acid and water. The preparation method of the base slurry includes the following steps: the processing requires 1 / 2 of the water, adding Starch, multi-component copolymer rubber, wa...

Embodiment 2

[0027] With reference to Example 1, the difference is that the yarn color is blue-gray.

[0028] The technological process is yarn cooking→multi-cylinder dyeing and oxidation→multiple washing→sizing→drying→separating yarn→spool (finished product).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com