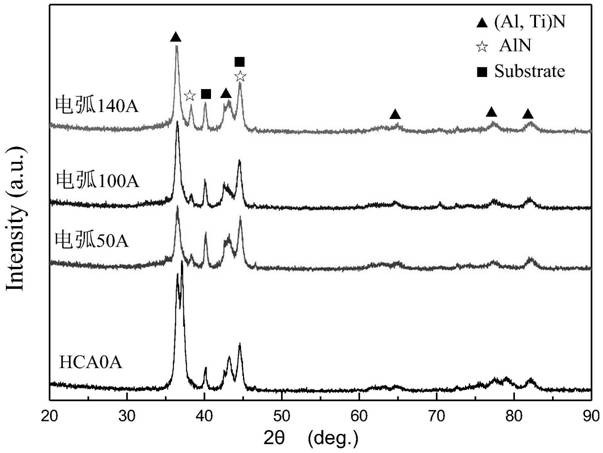

Multi-arc ion plating preparation method of AlTi target discharge AlTiN/AlN composite phase coating

A multi-arc ion plating and composite phase technology, applied in ion implantation plating, coating, metal material coating technology, etc., can solve the problem of low Al content in the coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0032] Embodiment 1: This embodiment is a multi-arc ion plating preparation method of an AlTi target discharge AlTiN / AlN composite phase coating, which is completed according to the following steps:

[0033] The multi-arc ion plating preparation method of a kind of AlTi target discharge AlTiN / AlN composite phase coating described in the present invention, it comprises the following steps:

[0034] 1. Select AlTi alloy and Ti metal as the multi-arc ion plating target, adjust the anode position of the auxiliary gas vacuum arc discharge, clean the sample with ultrasonic alcohol for 10-60 minutes, take it out and dry it, and then put it on the turntable in the vacuum chamber. less than 5×10 -3 Pa;

[0035] 2. Perform bias plasma discharge bombardment cleaning on the samples in the vacuum chamber;

[0036] The cleaning time described in step 2 is 5 to 50 minutes;

[0037] 3. Turn on the heating device to heat the vacuum chamber to 200-550°C, feed the working gas into the vacuum ...

specific Embodiment approach 2

[0047] Specific embodiment 2: This embodiment further explains Embodiment 1. The element ratio of the AlTi alloy described in Step 1 is 67 / 33; the auxiliary gas vacuum arc discharge anode described in Step 1 is respectively located in front of the AlTi target and in the center of the vacuum chamber. on the base.

specific Embodiment approach 3

[0048] Embodiment 3: This embodiment further explains Embodiment 1. The bias plasma discharge bombardment cleaning described in step 2 includes workpiece glow cleaning, auxiliary gas vacuum arc discharge cleaning, and the electrode on the base in the center of the vacuum chamber as an auxiliary Anode for gas vacuum arc discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com